High-nickel positive electrode material for non-aqueous electrolyte secondary battery and preparation method for high-nickel positive electrode material

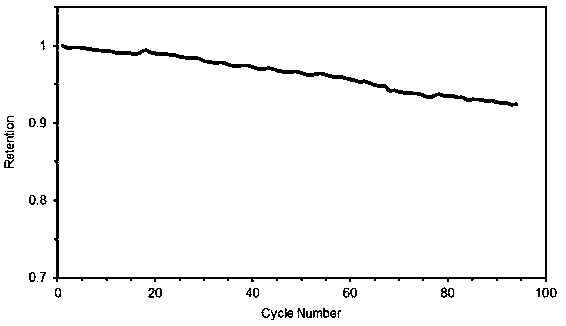

A non-aqueous electrolyte and positive electrode material technology, which is applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problem of poor contact between materials and conductive agents and binders, poor consideration of small particle sizes and electrolyte reactions, and increased Problems such as large material and electrolyte interface area can improve electrochemical performance, reduce lithium-nickel mixed discharge, improve cycle performance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of the high-nickel positive electrode material for the non-aqueous electrolyte secondary battery of the present embodiment is as follows:

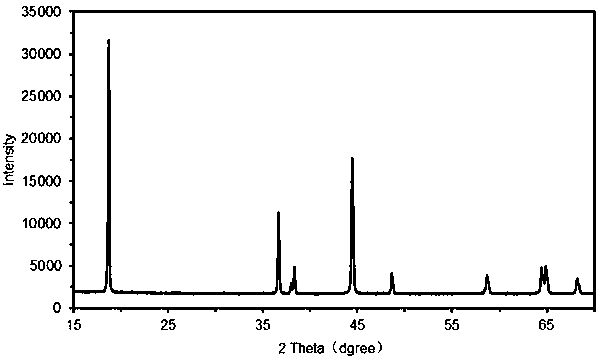

[0018] (1) Ni with D50 of 12 μm 0.80 co 0.10 mn 0.10 (OH) 2 The precursor, the lithium source is lithium hydroxide monohydrate, and the molar ratio is Li / (Ni+Co+Mn)=1.03. The additive is 20nm nano-magnesium oxide, and the proportion of magnesium added is 0.005mol. After mixing evenly with a ball mill, roast in an oxygen atmosphere at 780°C for 12 hours, crush the roasted product through a 200-mesh screen, wash with pure water and dry, take a certain amount of samples, and the additives are nano boron oxide, boron The proportion of the added element is 0.005mol. After mixing evenly, it is roasted at 450°C for 5 hours in an oxygen atmosphere and then sieved to obtain 12 μm Li 1.03 Ni 0.80 co 0.10 mn 0.10 Mg 0.005 B 0.005 o 2 Material;

[0019] (2) Ni with D50 of 3 μm 0.80 co 0.15 mn 0.05 (OH) 2 Th...

Embodiment 2

[0023] The preparation method of the high-nickel positive electrode material for the non-aqueous electrolyte secondary battery of the present embodiment is as follows:

[0024] (1) Ni with D50 of 13 μm 0.83 co 0.08 mn 0.09 (OH) 2 The precursor, the lithium source is lithium hydroxide monohydrate, and the molar ratio is Li / (Ni+Co+Mn)=1.04. The additive is 20nm nano-tungsten oxide, and the proportion of tungsten element added is 0.008mol. After mixing evenly with a ball mill, roast for 12 hours under an oxygen atmosphere at 770°C, crush the roasted product through a 200-mesh screen, wash with pure water and dry, take a certain amount of samples, and the additives are nano-tungsten oxide, tungsten The proportion of the added element is 0.005mol. After mixing evenly, it is roasted at 500°C for 5 hours under an oxygen atmosphere and sieved to obtain 13 μm Li 1.04 Ni 0.83 co 0.08 mn 0.09 W 0.013 o 2 Material;

[0025] (2) Ni with D50 of 4 μm 0.83 co 0.12 mn 0.05 (OH) 2...

Embodiment 3

[0029] The preparation method of the high-nickel positive electrode material for the non-aqueous electrolyte secondary battery of the present embodiment is as follows:

[0030] (1) Ni with D50 of 14 μm 0.65 co 0.15 mn 0.20 (OH) 2 The precursor, the lithium source is lithium carbonate, and the molar ratio is Li / (Ni+Co+Mn)=1.05. The additive is 20nm nano-zirconia, and the Zr element is added in a proportion of 0.01mol. It is mixed with a ball mill After homogenization, it was calcined at 860°C for 12 hours in an oxygen-air atmosphere, and the calcined product was crushed through a 200-mesh sieve to obtain 15 μm Li 1.05 Ni 0.65 co 0.15 mn 0.20 Zr 0.01 o 2 Material;

[0031] (2) Ni with D50 of 4 μm 0.65 co 0.20 mn 0.15 (OH) 2 The precursor, the lithium source is lithium carbonate, and the molar ratio is Li / (Ni+Co+Mn)=1.05. The additive is 20nm nano-zirconia, and the Zr element is added in a proportion of 0.01mol. It is mixed with a ball mill After uniformity, it was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com