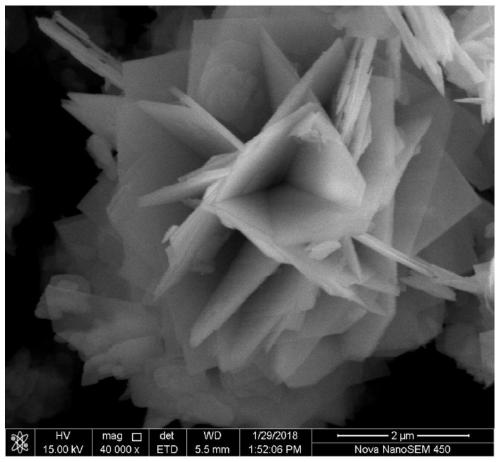

Preparation method of sheet-shaped g-C3N4 composite petal-shaped BiOBr photocatalytic material

A photocatalytic material, g-c3n4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as low photocatalytic efficiency, achieve good crystallinity, and the method is simple and easy to operate. , the effect of improving the ability to degrade dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] g-C 3 N 4 Preparation of:

[0023] (1) Weigh 2g of melamine and put it into a ceramic crucible, cover the ceramic crucible with a lid, and place it in a tubular heating furnace to raise the temperature to 550°C; the heating rate is 5°C / min, and the heating time is 4h to obtain a light yellow color g-C 3 N 4 (Graphite-like phase C 3 N 4 ), which is ground for later use;

[0024] BiOBr / g-C 3 N 4 Preparation of:

[0025] (2) Weigh 89.75mg of cetyltrimethylammonium bromide and place it in a small beaker, measure 16ml of ethylene glycol with a measuring cylinder and pour it into the beaker, stir for 60min, as solution A; at the same time take 119.25mg of nitric acid pentahydrate Put bismuth in another 50ml small beaker, add 12ml nitric acid (2M), stir for 1h, as solution B; pour solution B into solution A, then weigh 300mg of g-C obtained in step (1) 3 N 4 Add to the mixed solution, ultrasonic 10min;

[0026] (3) Place the suspension obtained in step (2) in a 50m...

Embodiment 2

[0029] g-C 3 N 4 Preparation of:

[0030] (1) is identical with the step (1) of embodiment 1;

[0031] BiOBr / g-C 3 N 4 Preparation of:

[0032] (2) Weigh 359mg of cetyltrimethylammonium bromide and place it in a small beaker, measure 16ml of ethylene glycol with a graduated cylinder and pour it into the beaker, stir for 60min, as solution A; at the same time, take 477mg of bismuth nitrate pentahydrate and put In another 50ml small beaker, add 12ml of nitric acid (2M), stir for 1h, as solution B; pour solution B into solution A, then weigh 300mg of g-C obtained in step (1) 3 N 4 Add to the mixed solution, ultrasonic 10min;

[0033] (3) Place the suspension obtained in step (2) in a 50ml reaction kettle, and react at 160 degrees Celsius for 12h;

[0034](4) After the reaction in step (3) is completed, centrifuge the resulting product to obtain a precipitate, then wash it three times with deionized water and absolute ethanol, and dry the cleaned precipitate in a vacuum dr...

Embodiment 3

[0036] g-C 3 N 4 Preparation of:

[0037] (1) is identical with the step (1) of embodiment 1;

[0038] BiOBr / g-C 3 N 4 Preparation of:

[0039] (2) Weigh 1.436g of cetyltrimethylammonium bromide and place it in a small beaker, measure 16ml of ethylene glycol with a measuring cylinder and pour it into the beaker, stir for 60min, as solution A; at the same time, take 1.9308g of nitric acid pentahydrate Put bismuth in another 50ml small beaker, add 12ml nitric acid (2M), stir for 1h, as solution B; pour solution B into solution A, then weigh 300mg of g-C obtained in step (1) 3 N 4 Add to the mixed solution, ultrasonic 10min;

[0040] (3) Place the suspension obtained in step (2) in a 50ml reaction kettle, and react at 160 degrees Celsius for 12h;

[0041] (4) After the reaction in step (3) is completed, centrifuge the resulting product to obtain a precipitate, then wash it three times with deionized water and absolute ethanol, and dry the cleaned precipitate in a vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com