A method for efficiently eliminating the wrinkles of graphene by chemical vapor deposition

A technology of chemical vapor deposition and graphene, which is applied in chemical instruments and methods, graphene, inorganic chemistry, etc., can solve the problems of uneven mass distribution of graphene film, reduce the oxidation resistance of graphene, etc., and achieve less defects and better surface Ultra-flattening, wrinkle-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

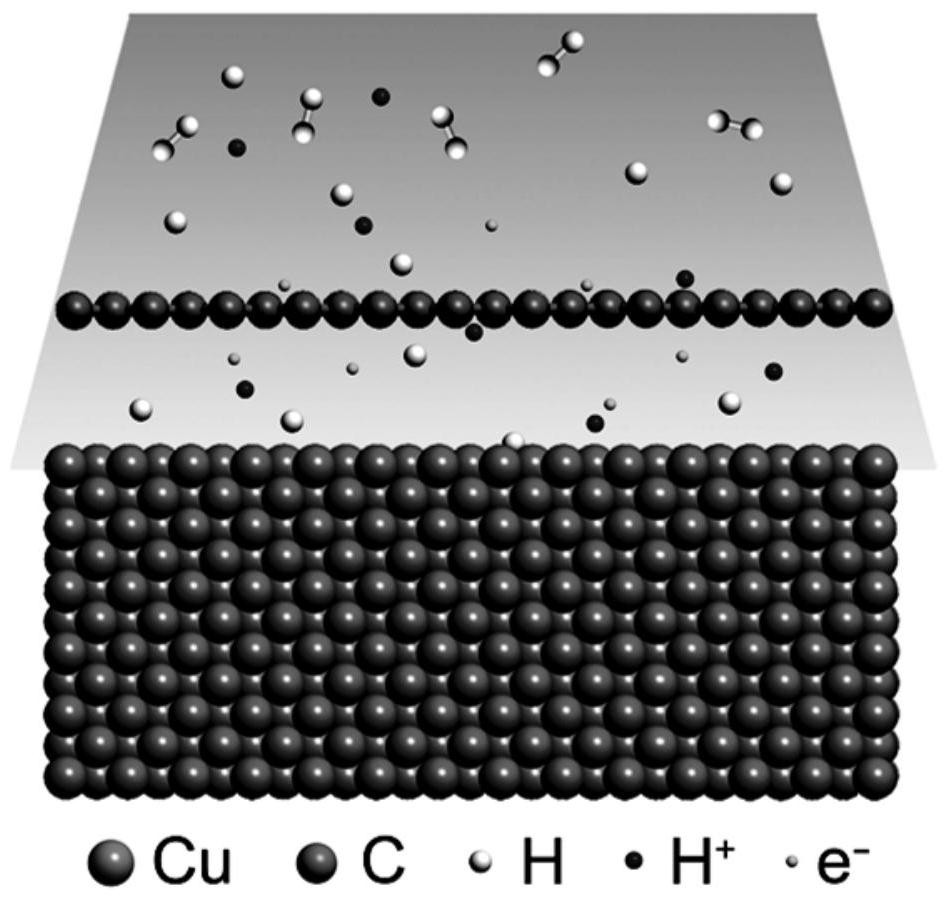

Method used

Image

Examples

Embodiment 1

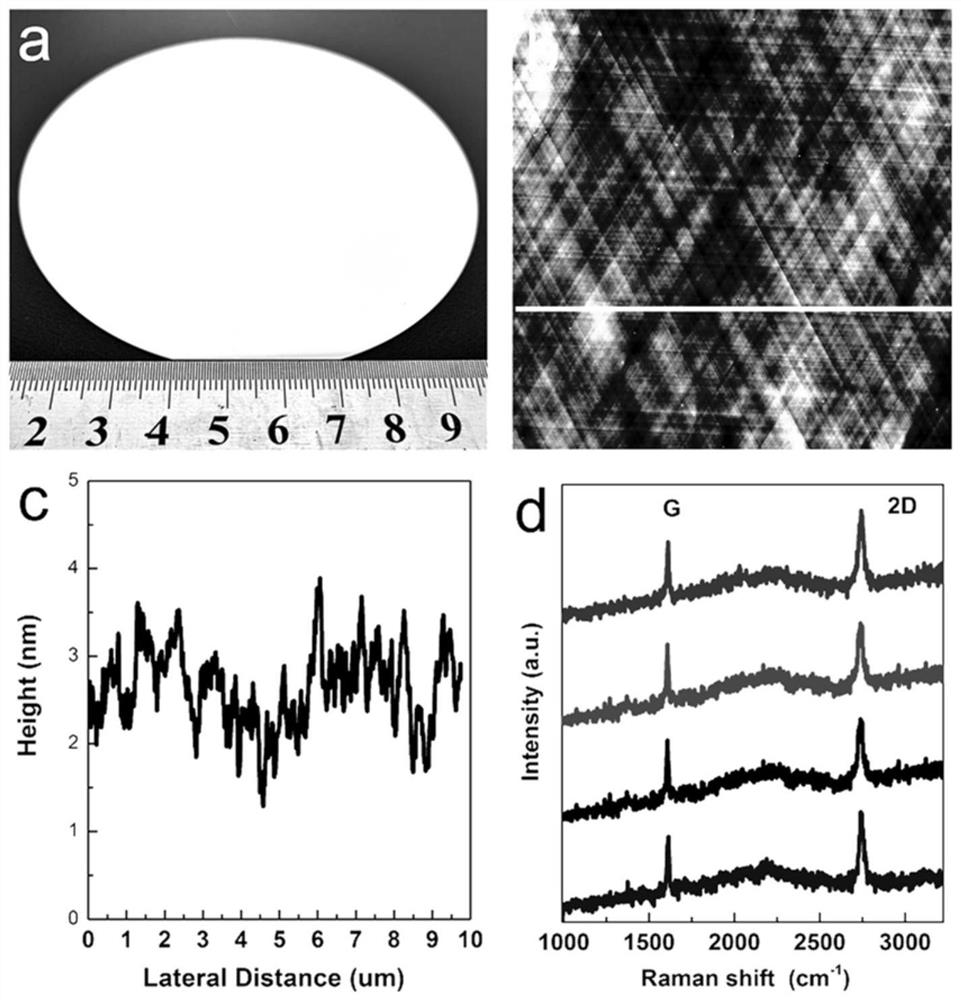

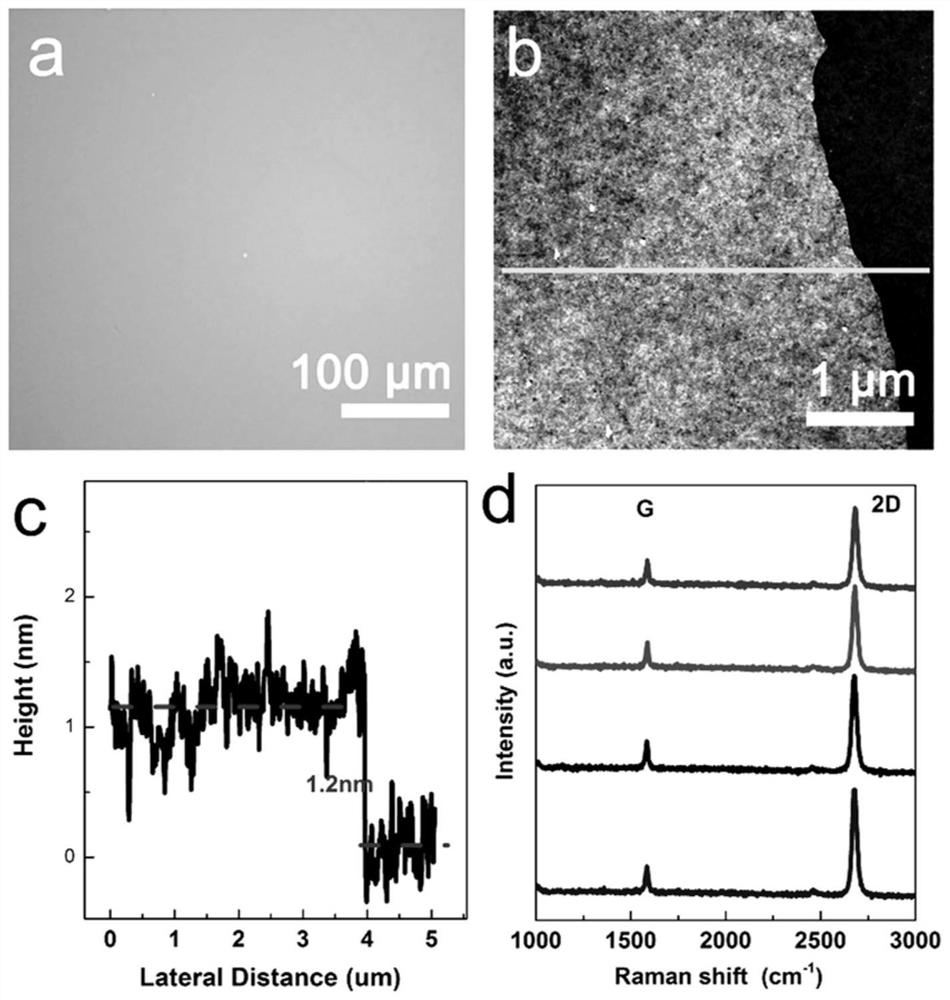

[0038] Grown wrinkle-free graphene on a copper substrate by plasma assistance, specifically: a smooth copper film (plated on sapphire), placed in a tube furnace and heated to 1000 ° C and maintained for 40 minutes to obtain relatively smooth copper surface. Put the copper substrate into the plasma-assisted chemical vapor deposition system, pass hydrogen and methane in the ratio of 20:1 (total gas flow is 200sccm), stabilize the pressure of the reaction chamber to 10Pa through the pressure regulating valve, and heat it to 500~800℃ , and keep it for 1 to 10 minutes. Start the inductively coupled plasma generator, adjust the power to 10-50W, and control the grain size and growth rate of the graphene film by changing the plasma power and time. Generally, a single-layer, wrinkle-free film can be obtained after 2-5 minutes of growth. Graphene film. After the growth is completed, cool down naturally, and turn off the gas when the temperature drops to near room temperature.

[0039...

Embodiment 2

[0041] The difference from Example 1 is that:

[0042] Grown wrinkle-free graphene on a copper substrate by plasma assistance, specifically: a smooth copper film (plated on sapphire), placed in a tube furnace and heated to 1000 ° C and maintained for 40 minutes to obtain relatively smooth copper surface. Put the copper substrate into the plasma-assisted chemical vapor deposition system, feed hydrogen and methane in a ratio of 20:1 (in this embodiment, the total gas flow can be 50-1000sccm), and stabilize the pressure of the reaction chamber through a pressure regulating valve is 10Pa, heated to 500-800°C, and kept for 30m minutes (in this embodiment, the keeping time can be between 5min-2h). Start the inductively coupled plasma generator, adjust the power to 10-50W, and control the grain size and growth rate of the graphene film by changing the plasma power and time. Generally, a single-layer, wrinkle-free film can be obtained after 2-5 minutes of growth. Graphene film (in t...

Embodiment 3

[0045] The difference from Example 1 is that:

[0046] Grown wrinkle-free graphene on a nickel substrate by plasma assistance (in this embodiment, the substrate uses nickel, platinum, gold, silver, rhodium, iridium, ruthenium and other metal and alloy thin films, taking nickel as an example) , specifically: a smooth nickel film (plated on sapphire), placed in a tube furnace and heated to 1000° C. and maintained for 40 minutes to obtain a relatively smooth nickel surface. Put the nickel substrate into the plasma-assisted chemical vapor deposition system, pass hydrogen and methane in a ratio of 40:1 (total gas flow is 200sccm), stabilize the pressure of the reaction chamber to 10Pa through a pressure regulating valve, and heat it to 500-800℃ , and keep it for 1 to 10 minutes. Start the inductively coupled plasma generator, adjust the power to 10-50W, and control the grain size and growth rate of the graphene film by changing the plasma power and time. Generally, a single-layer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com