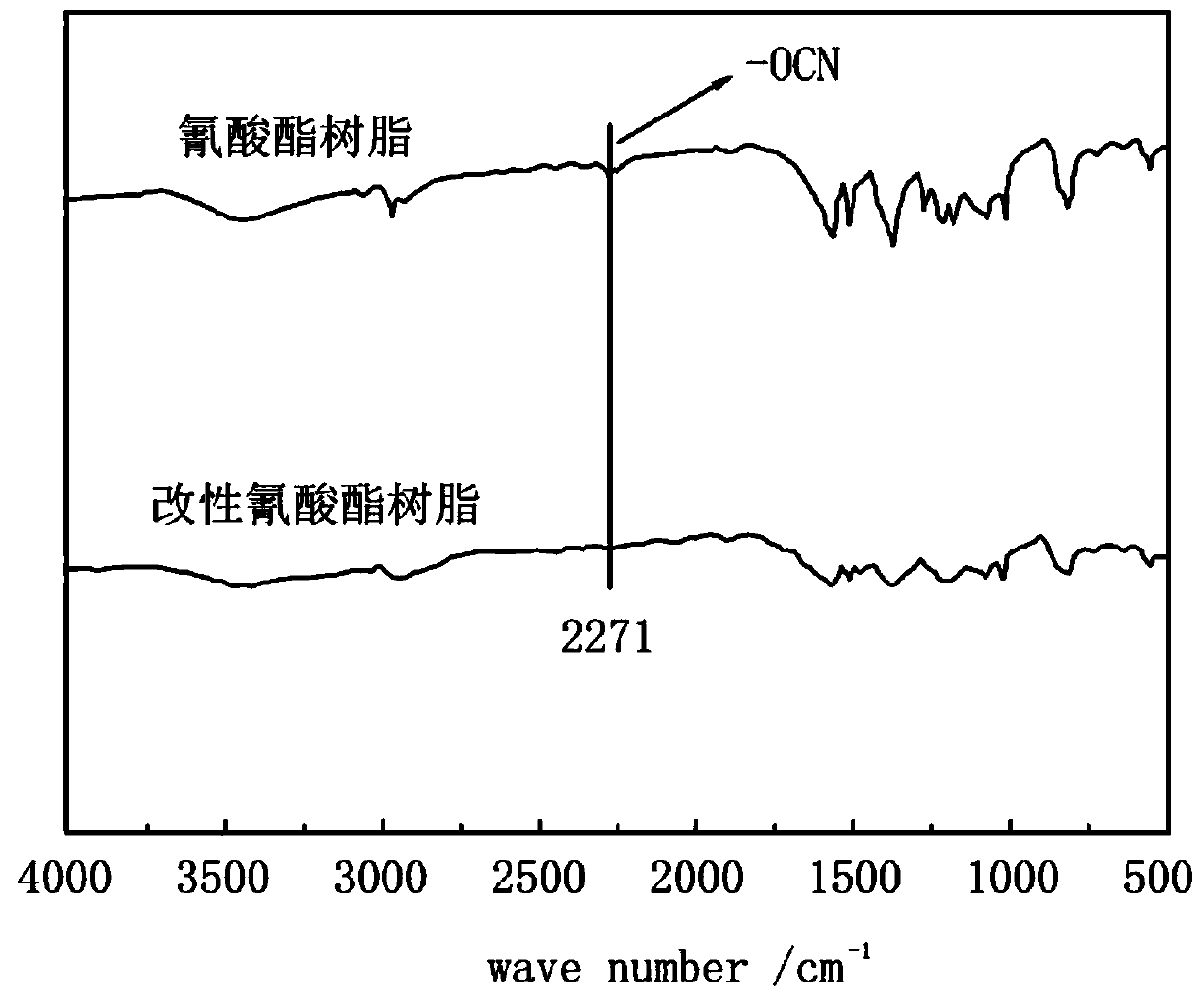

Polyphenyl ether modified cyanate resin copper-clad plate and preparation method thereof

A technology of cyanate resin and polyphenylene ether resin, applied in the field of polyphenylene ether modified cyanate resin copper clad laminate and its preparation, can solve the problems of product corrosion of fine wiring, generation of harmful compounds, halide dissociation, etc. , to achieve good market prospects and economic benefits, reduce production costs, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A polyphenylene ether modified cyanate resin copper clad laminate and a preparation method thereof, wherein the polyphenylene ether modified cyanate resin composition comprises the following components by weight: 100 parts by weight of polyphenylene ether resin, cyanate ester 300 parts of resin, 4 parts of epoxy resin, 15 parts of polyolefin resin, 20 parts of bisphenol A, 4 parts of accelerator, 50 parts of filler, 10 parts of flame retardant, some alkali-free glass fiber cloth, solvent, silane coupling agent .

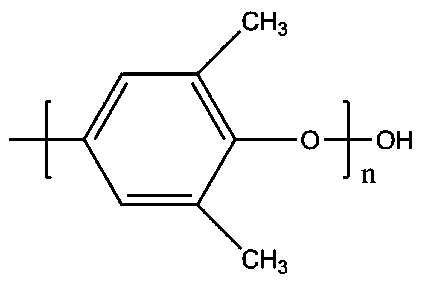

[0046] Further, the structural formula of the polyphenylene ether resin is as follows:

[0047]

[0048] In the formula, n is an integer of 1-30.

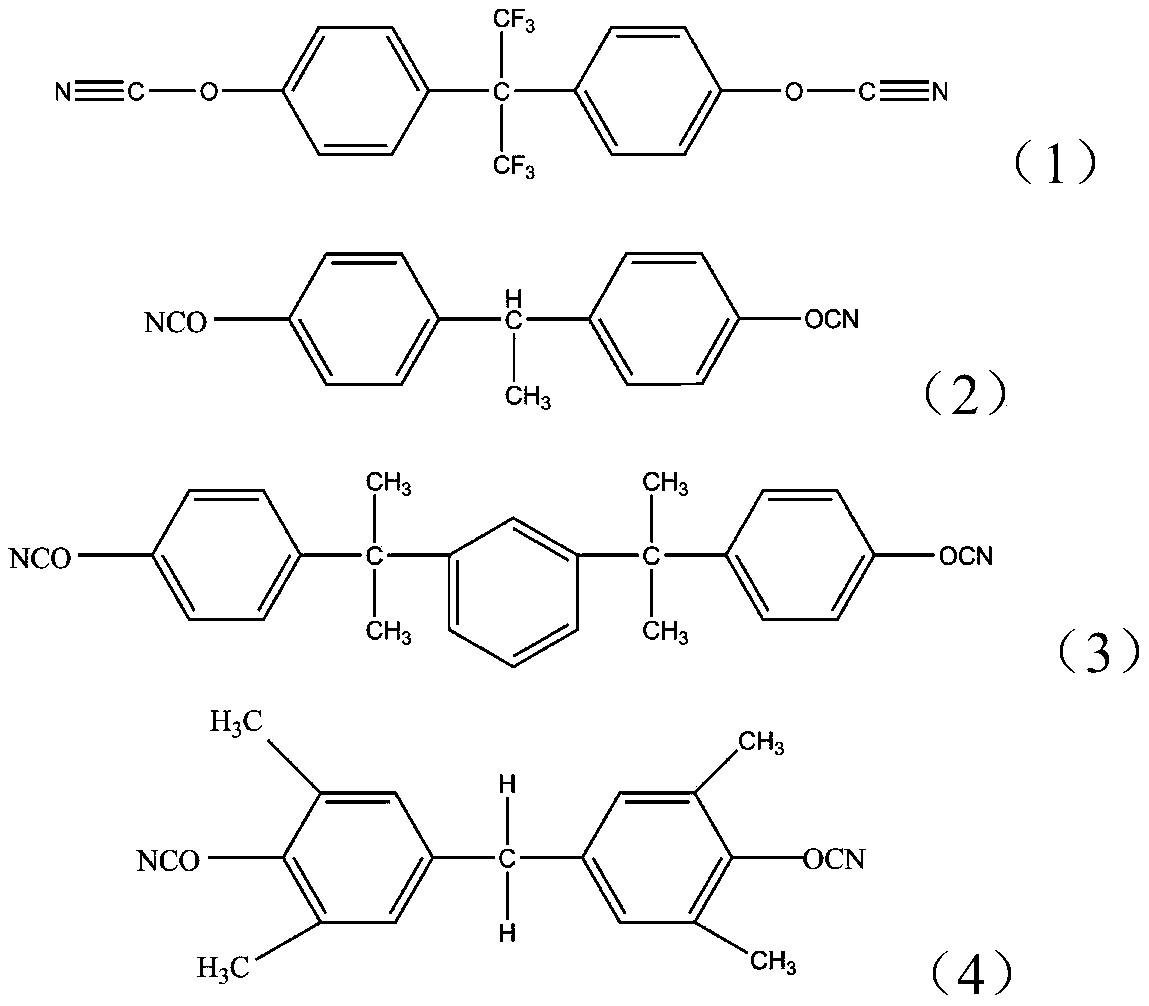

[0049] Further, the cyanate resin is a bisphenol E type cyanate, and the structural formula of the cyanate resin is as follows:

[0050]

[0051] Further, the polyolefin resin is a styrene-butadiene copolymer.

[0052] Further, the solvent includes toluene, methanol, deionized water, ethanol and dichlorome...

Embodiment 2

[0071] A polyphenylene ether modified cyanate resin copper clad laminate and a preparation method thereof, wherein the polyphenylene ether modified cyanate resin composition comprises the following components by weight: 100 parts by weight of polyphenylene ether resin, cyanate resin 400 parts, 2.5 parts of epoxy resin, 10 parts of polyolefin resin, 20 parts of bisphenol A, 4 parts of accelerator, 50 parts of filler, 12 parts of flame retardant, some alkali-free glass fiber cloth, solvent, silane coupling agent.

[0072] Further, the structural formula of the polyphenylene ether resin is as follows:

[0073]

[0074] In the formula, n is an integer of 1-30.

[0075] Further, the cyanate resin is tetramethyl bisphenol F type cyanate resin, and the structural formula of the cyanate resin is as follows respectively:

[0076]

[0077] Further, the polyolefin resin is a styrene-butadiene-divinylbenzene copolymer.

[0078] Further, the solvent includes toluene, methanol, deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com