Two-layer coated modified ternary cathode high-nickel material and preparation method thereof

A double-layer coating, high-nickel technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high residual alkali content, a large amount of gas and heat, instability and other problems, and achieve the improvement of the first discharge specific capacity, The effect of improving electrochemical stability and less demanding production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the preparation method of the above-mentioned double-layer coating modified ternary positive high-nickel material, comprising the following three steps:

[0033] Step 1, the precursor nickel-cobalt-manganese hydroxide is mixed with manganese salt to obtain a precursor coated with manganese salt;

[0034] Step 2, the product of step 1 is mixed with lithium salt, and sintered to obtain a ternary positive high-nickel material coated with manganese oxide;

[0035] In step 3, the product obtained in step 2 is mixed with metal oxide and sintered to obtain a double-layer coated ternary positive high-nickel material.

[0036] Above-mentioned preparation method comprises the following steps:

[0037] Step 1, the manganese salt is uniformly dissolved in the solvent I first, then the precursor nickel cobalt manganese hydroxide is added, stirred, heated, and the solvent I is removed to obtain a ternary cathode material precursor coated with the ...

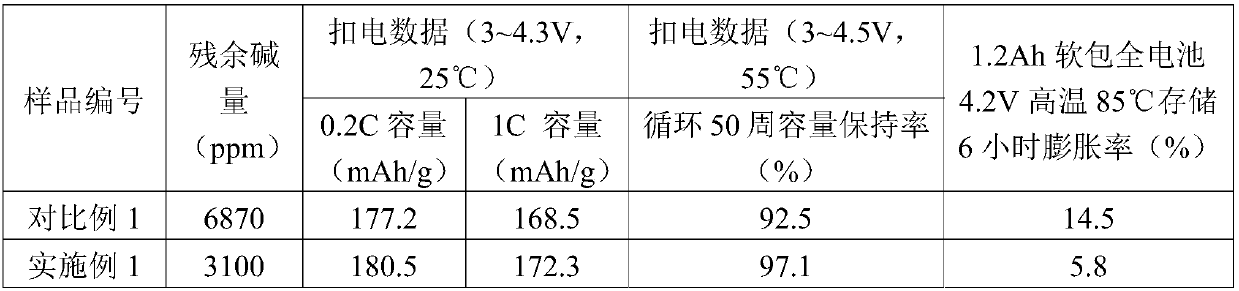

Embodiment 1

[0077] First, ultrasonically dissolve 20g of manganese acetate in 400g of ethanol solvent, and then slowly add high-nickel ternary cathode material precursor Ni 0.65 co 0.20 mn 0.15 (OH) 2 1000g,

[0078] After stirring at 500rpm for 30min, heat at 70°C until the solvent is completely evaporated to obtain a precursor of manganese acetate;

[0079] Then the precursor of manganese acetate bag that obtains is pulverized, crosses 300 mesh sieves, weighs 800g again, weighs required lithium carbonate 332g by lithium proportioning 1.05 again. After ball milling and mixing evenly, sintering at a high temperature of 870°C for 15 hours in a muffle furnace with 45% oxygen, and after natural cooling, a ternary positive high-nickel material coated with manganese oxide is obtained;

[0080] Pass the obtained manganese oxide-coated ternary positive high-nickel material through a 300-mesh sieve, then weigh out 700g, then accurately weigh 1.4g of nano-alumina and mix it with it, and use a ...

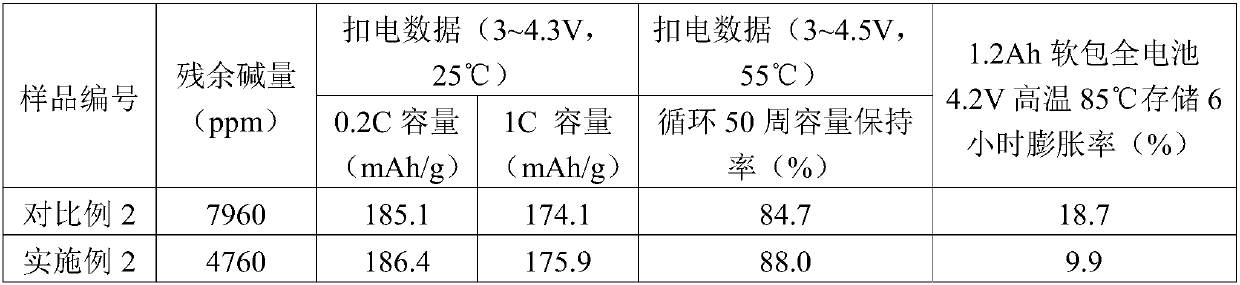

Embodiment 2

[0082] Dissolve 25g of manganese acetate uniformly in 400g of water solvent, then slowly add Ni 0.70 co 0.20 mn 0.10 (OH) 2 1000g, after stirring at 500rpm for 30min, heat at 70°C until the solvent is completely evaporated to obtain a precursor of manganese acetate;

[0083] Then the precursor of the bag manganese acetate that obtains is pulverized, crosses 300 mesh sieves, then weighs the precursor 800g of the bag manganese acetate that obtains, weighs required lithium carbonate 332g by lithium proportioning 1.05 again. After mixing uniformly by ball milling, sintering at 840°C for 15 hours in a muffle furnace with 45% oxygen, and after natural cooling, a ternary positive high-nickel material coated with manganese oxide is obtained;

[0084] The ternary anode high-nickel material of cladding manganese oxide obtained is passed through a 300 mesh sieve, and then weighed and taken out 700g. Accurately weigh 1.4g of nano-titanium oxide additive, then mix the titanium oxide ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com