Preparation method and application of biochar by enriching copper element in ciliate desert grass

A technology of centipede grass and biochar, applied in the direction of non-metal elements, chemical instruments and methods, carbon compounds, etc., can solve the problems of limited metal content, high cost, and low level of plant biomass, and achieve low production cost and high chemical efficiency. and biological stability, the effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

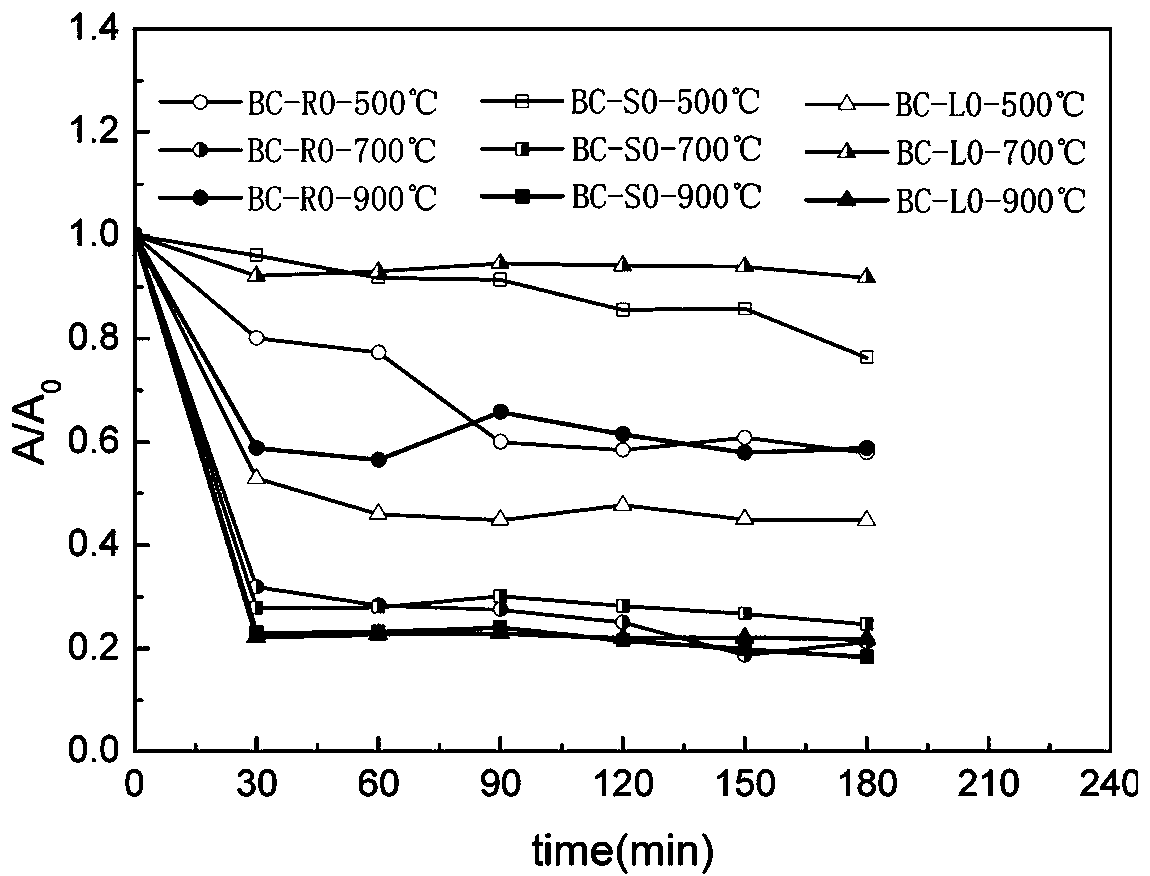

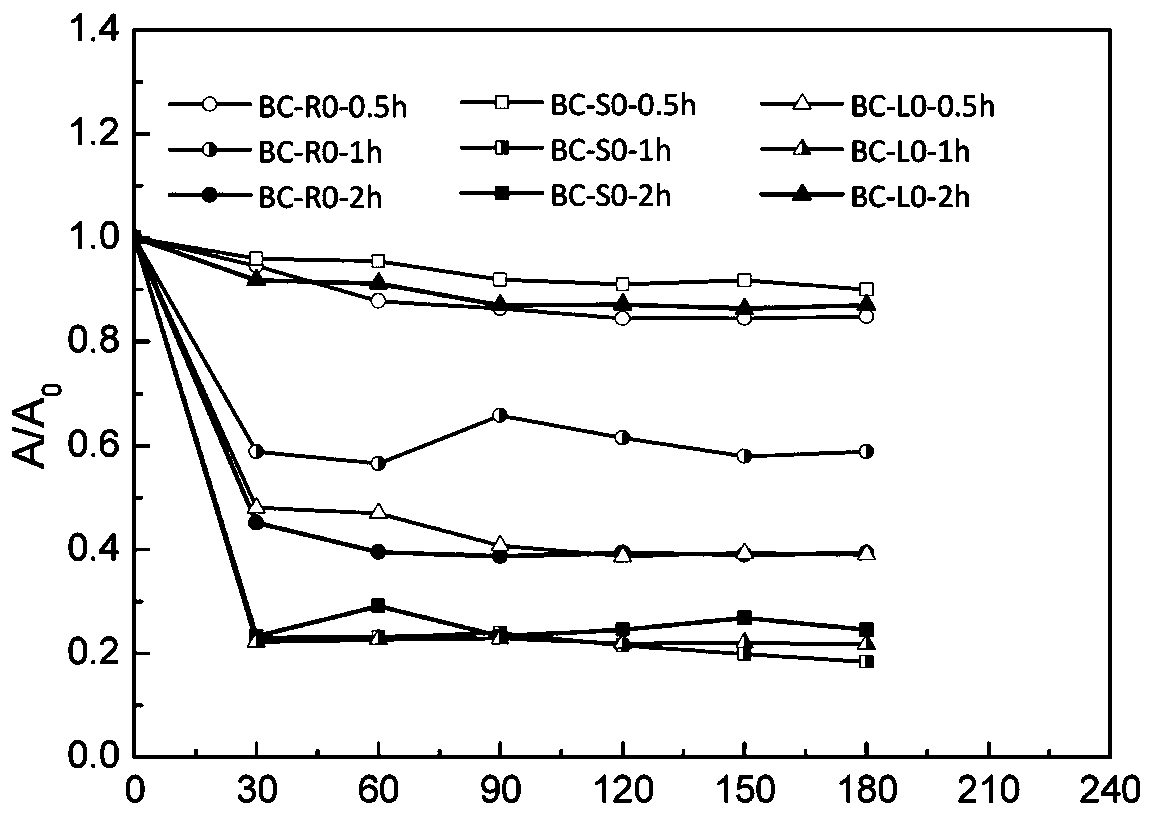

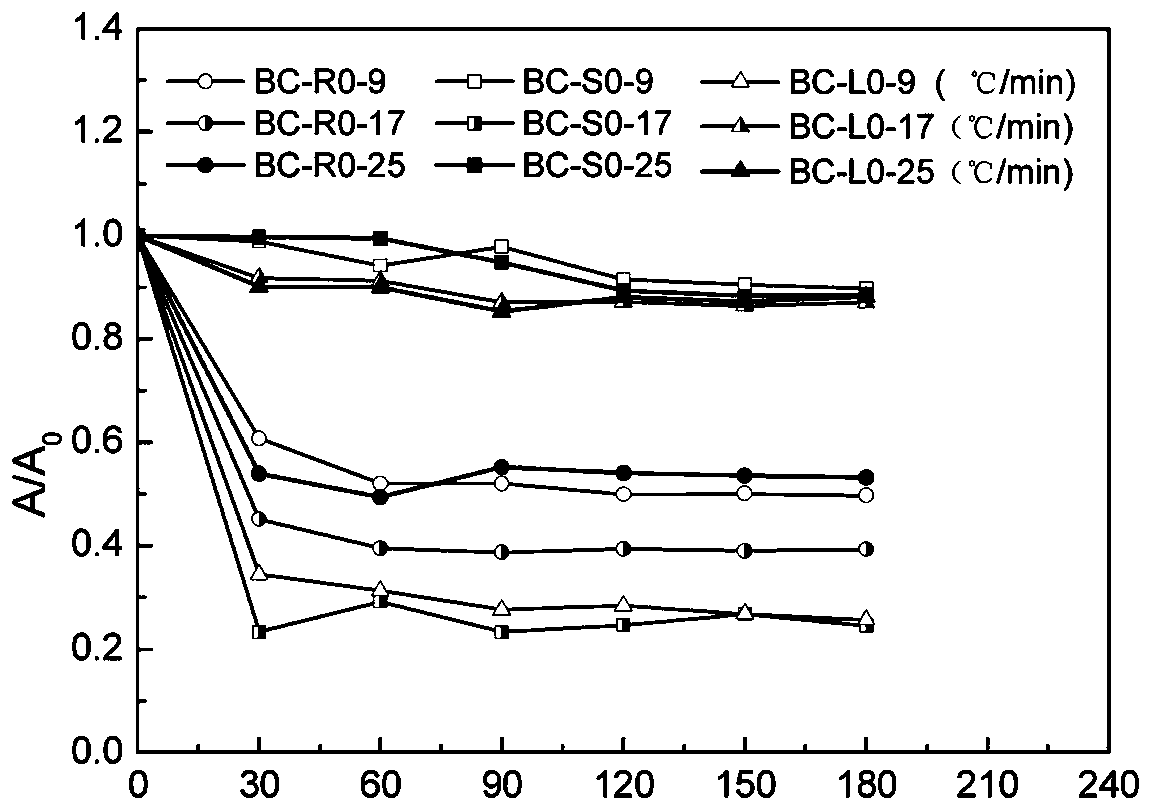

Image

Examples

Embodiment 1

[0048] Experimental equipment: electric heating constant temperature blast drying oven (DGG-9123A type, Shanghai), tubular resistance furnace (Hubei Yingshan County Jianli Electric Furnace Manufacturing Co., Ltd., model: SK2), KSW-4D-11A type temperature controller, high speed Centrifuge (TG16W, Changsha), vacuum pump (Yuhua Instrument, SHZ-DⅢ), XL30 scanning electron microscope (Philips, Netherlands), JW-BK112 specific surface area pore size analyzer (BET, Beijing Jingwei Gaobo Science and Technology Co., Ltd. ), Autosorb-1 type N 2 Physical adsorption instrument (Quantachrome, the United States), photoreactor (XPA series photochemical reaction instrument, XPA series-7 multi-tube stirring instrument), UV-1800PC ultraviolet-visible spectrophotometer (Hitachi, Japan), CHA-S constant temperature oscillation (Guohua Enterprise), D / max2500 type ray diffractometer (Rigaku, Japan), Delta320pH meter (Mettler-Toledo, Shanghai Co., Ltd.), Pinnacle 900TPerkinElmer type atomic absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com