Preparation method and application of glycosyl metal porous coordination polymer

A porous coordination and polymer technology, applied in the direction of ion exchange water/sewage treatment, etc., can solve the problems of difficult large-scale preparation, low synthesis cost, and small equipment investment, and achieve a green synthesis method, good stability and safety , easy to enlarge the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

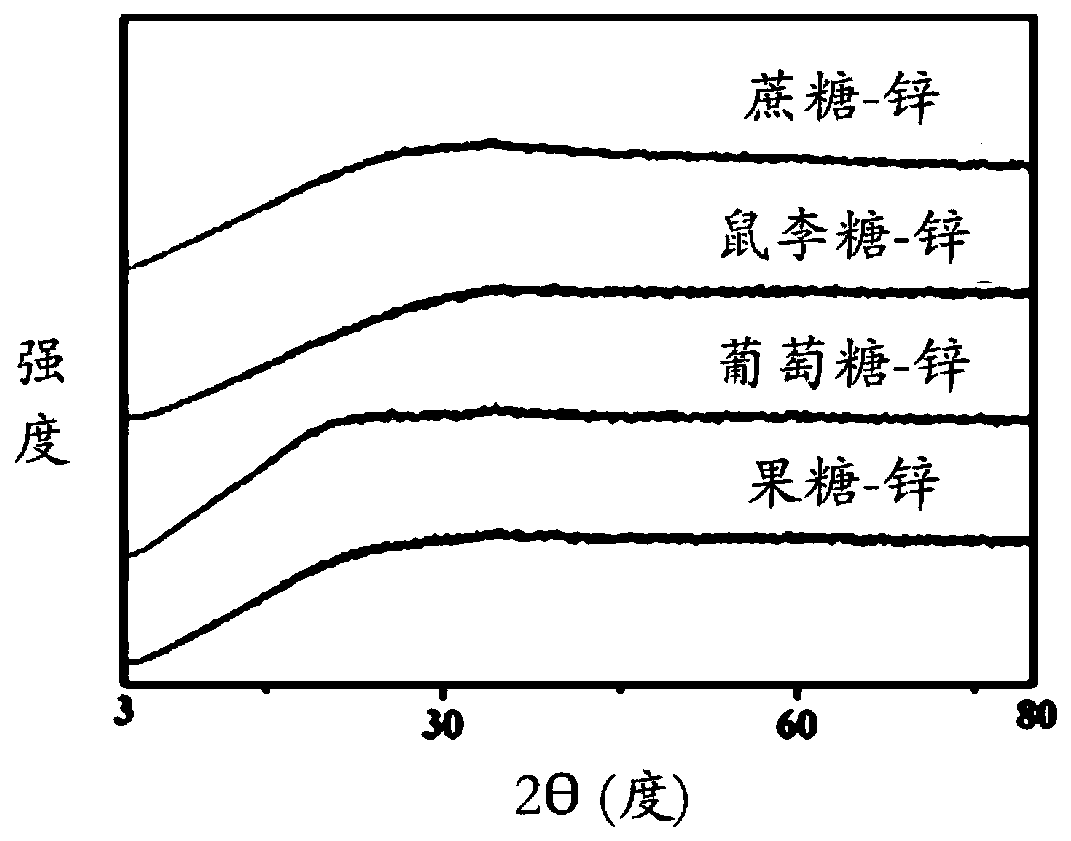

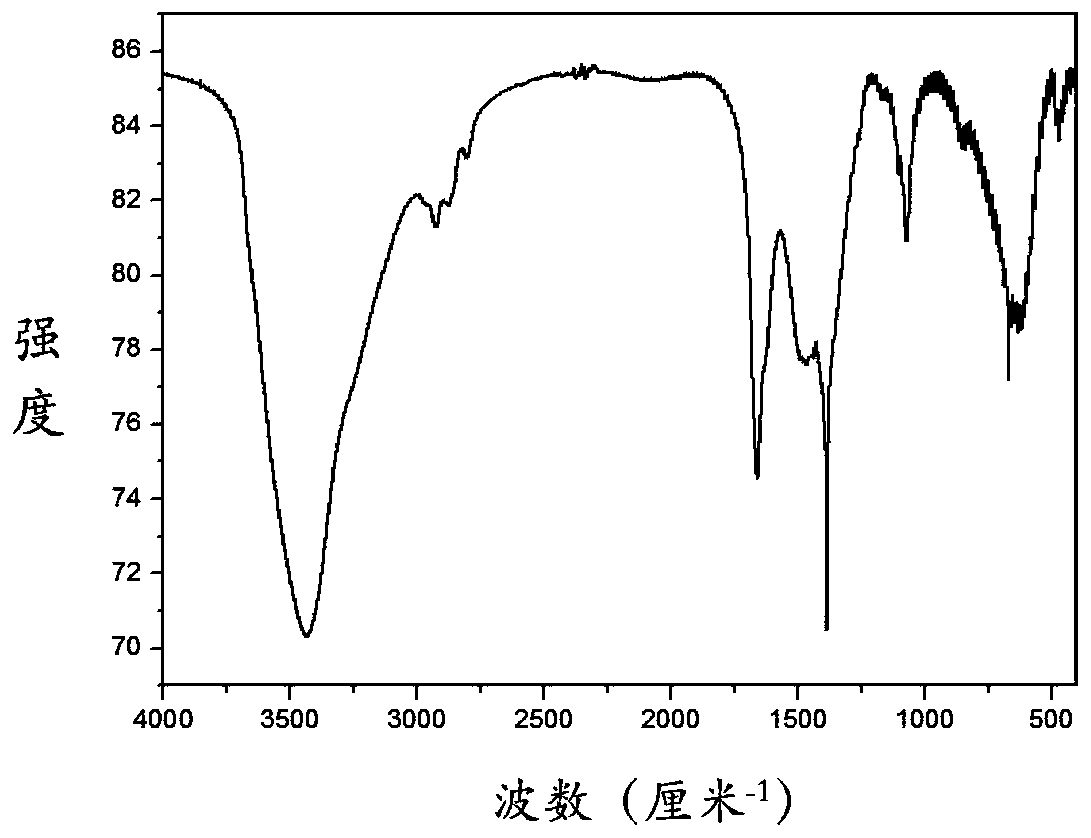

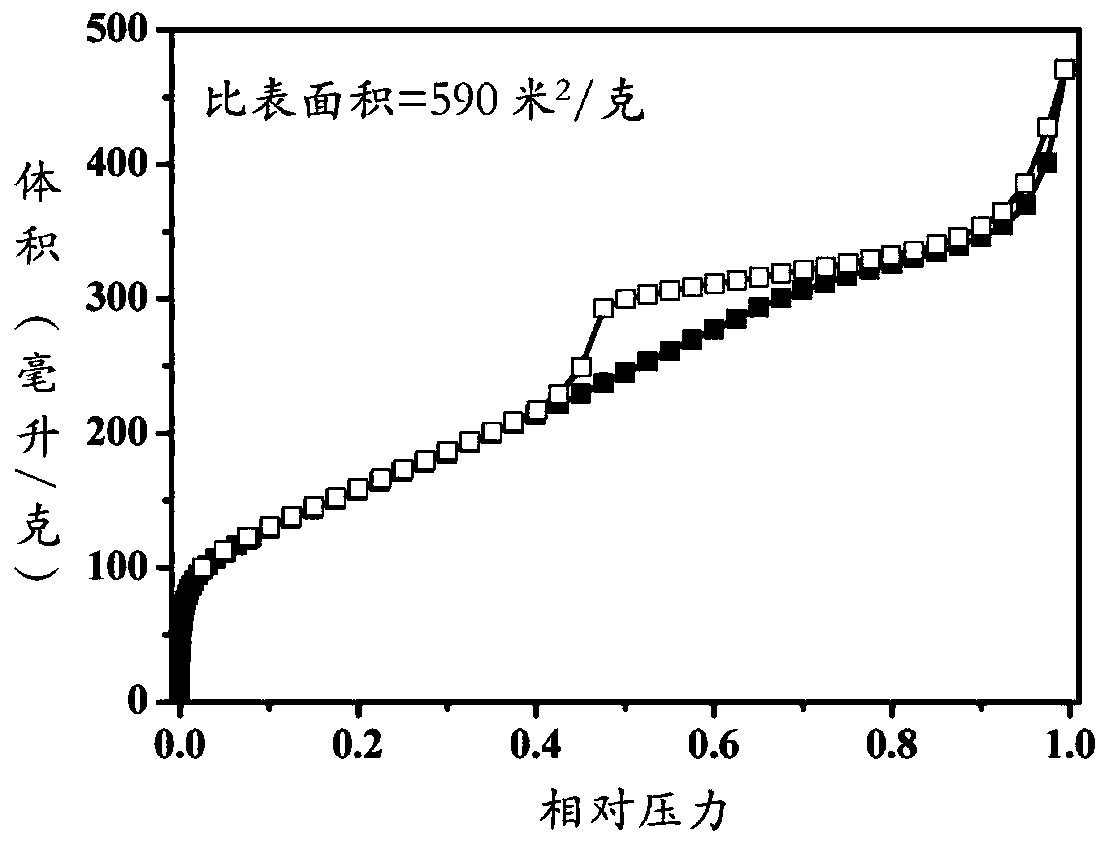

[0032] (1) Take sucrose (600mg), zinc acetate (Zn(OAC) 2 , 300mg) and potassium carbonate (1200mg) were added in a clean ball mill jar, weighed and added to the ball mill jar, and a coordination reaction occurred in a ball mill on a planetary ball mill for 20min to prepare a porous coordination polymer containing sucrose-Zn. The final porous coordination polymer was rinsed three times with deionized water repeatedly. X-ray diffraction characterization showed that the porous coordination polymers prepared from polysaccharide metals belonged to amorphous materials. Infrared data indicated that the glycosyl ligands and metal ions were successfully coordinated. The gas adsorption test shows that the obtained coordination polymer has a porous structure and a high specific surface area.

Embodiment 2

[0034] (1) Fructose (600mg), zinc acetate (Zn(OAC) 2 , 300mg) and potassium carbonate (1200mg) were added in a clean ball mill jar, weighed and added to the ball mill jar, and a coordination reaction occurred in a ball mill on a planetary ball mill for 20min to prepare a porous coordination polymer containing sucrose-Zn. The final porous coordination polymer was rinsed three times with deionized water repeatedly.

[0035] (2) Add the polymer prepared in step (1) to potassium hydroxide (KOH) according to different mass ratios (1:0, 1:1, 1:2, etc.) Carry out carbonization in an inert gas, heat up from room temperature to 400-800 °C at 2-5 °C / min, keep warm for 2 hours, and cool to room temperature to obtain a black solid. The resulting black solid was acid-washed (1M HCl), washed overnight, and then washed twice with pure water to remove potassium salts. Then vacuum-dry at 80° C. overnight to obtain the porous carbon material based on the porous coordination polymer of the pre...

Embodiment 3

[0037](1) Add maltose (600mg), nickel acetate (Ni(OAC)2, 300mg) and potassium carbonate (1200mg) into a clean ball mill jar, weigh them into the ball mill jar, and ball mill on a planetary ball mill for 20 minutes to form a compound The maltose-Ni porous coordination polymer was prepared through a site reaction, and the reacted porous coordination polymer was washed with deionized water for 3 times.

[0038] (2) Add the polymer prepared in step (1) to potassium hydroxide (KOH) according to different mass ratios (1:0, 1:1, 1:2, etc.) Carry out carbonization in an inert gas, heat up from room temperature to 400-800 °C at 2-5 °C / min, keep warm for 2 hours, and cool to room temperature to obtain a black solid. The resulting black solid was acid-washed (1M HCl), washed overnight, and then washed twice with pure water to remove potassium salts. Then vacuum-dry at 80° C. overnight to obtain the porous carbon material based on the porous coordination polymer of the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com