Bio-based wood-plastic composite and preparation method thereof

A wood-plastic composite material, bio-based technology, applied in the field of wood-plastic composite materials, can solve the problems of easy deformation buckling, poor product strength and color fastness, poor heat resistance, etc., to improve the elongation at break, Excellent anti-UV properties, enhance the effect of enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

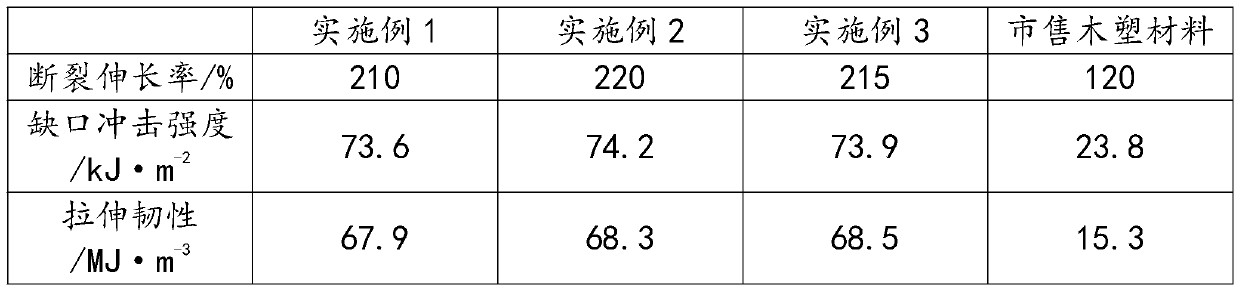

Examples

preparation example Construction

[0050] The preparation method of the bio-based wood-plastic composite material comprises the following steps:

[0051] Step 1. Weigh the raw materials according to the parts by weight, and dry the PLA resin, modified lignin, modified filler, and flame retardant in an air-blast drying oven at 80°C for 6-7 hours;

[0052] Step 2: Dissolve the PLA resin in methylene chloride, add the modified lignin to the methylene chloride solution of PLA, stir magnetically for 4 hours at room temperature, disperse evenly, and slowly volatilize the solvent at room temperature for 12-15 hours, then Put it in a vacuum oven at 40°C and dry for 10 hours to obtain the wood-plastic base material;

[0053] By blending the modified lignin and the PLA resin in the dichloromethane solvent, the contact area between the two can be increased, so that the modified lignin and the PLA resin can be mixed evenly, and the degree of dispersion of the modified lignin in the PLA resin can be improved. ;

[0054] S...

Embodiment 1

[0057] The bio-based wood-plastic composite material is made of the following raw materials in parts by weight: 50 parts of PLA resin, 100 parts of methylene chloride, 15 parts of modified lignin, 8 parts of modified filler, 1 part of flame retardant, and 1 part of antioxidant 0.5 part of lubricant, 0.3 part of stabilizer, 0.1 part of processing aid;

[0058] The bio-based wood-plastic composite material is made by the following steps:

[0059] Step 1. Weigh the raw materials according to the parts by weight, and dry the PLA resin, modified lignin, modified filler, and flame retardant in an air-blast drying oven at 80°C for 6-7 hours;

[0060] Step 2: Dissolve the PLA resin in methylene chloride, add the modified lignin to the methylene chloride solution of PLA, stir magnetically for 4 hours at room temperature, disperse evenly, and slowly volatilize the solvent at room temperature for 12 hours, then place Dry in a vacuum oven at 40°C for 10 hours to obtain the wood-plastic b...

Embodiment 2

[0064] The bio-based wood-plastic composite material is made of the following raw materials in parts by weight: 55 parts of PLA resin, 110 parts of methylene chloride, 17.5 parts of modified lignin, 10 parts of modified filler, 1.5 parts of flame retardant, and 1.5 parts of antioxidant part, 0.7 part of lubricant, 0.4 part of stabilizer, 0.15 part of processing aid;

[0065] The bio-based wood-plastic composite material is made by the following steps:

[0066] Step 1. Weigh the raw materials according to the parts by weight, and dry the PLA resin, modified lignin, modified filler, and flame retardant in an air-blast drying oven at 80°C for 6-7 hours;

[0067] Step 2: Dissolve the PLA resin in methylene chloride, add the modified lignin to the methylene chloride solution of PLA, stir magnetically for 4 hours at room temperature, disperse evenly, and slowly volatilize the solvent at room temperature for 12-15 hours, then Put it in a vacuum oven at 40°C and dry for 10 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com