Heat transfer printing foaming ink and preparation method thereof and application of heat transfer printing foaming ink in plastic products

A technology of foaming ink and defoaming agent, which is applied in the direction of copying/marking, ink, printing, etc., can solve the problems of insufficient adhesion, low foaming ratio, and environmental pollution, and achieve bright colors and high tear strength , good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

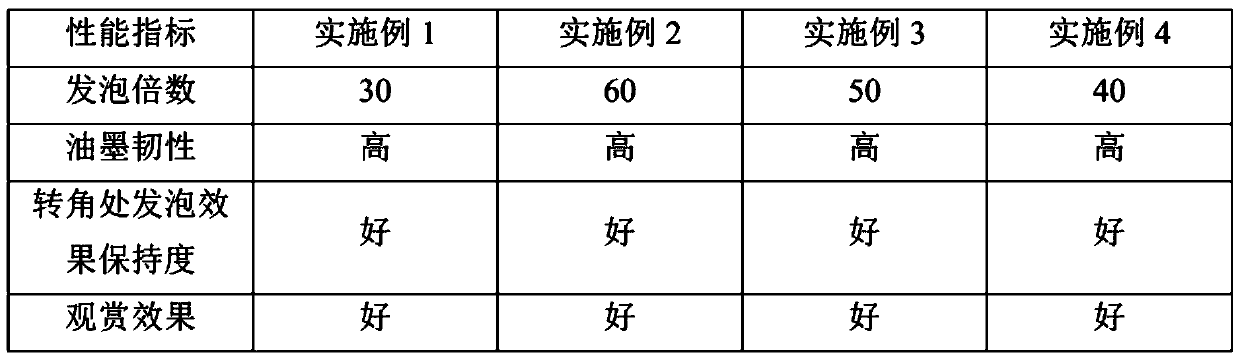

Examples

Embodiment 1

[0039] (1) Add 0.02kg of K12, 0.5kg of polyvinyl alcohol, 2kg of n-hexane, 6kg of γ-chloropropyl trichlorosilane, 3kg of methyl methacrylate, 2kg of butyl acrylate, 0.2kg of KH570 and 15kg of water into the reaction vessel , and stir evenly to obtain a pre-emulsion.

[0040] (2) Take a pre-emulsion with 30% of the total mass of the pre-emulsion obtained in step (1), quickly add 0.07 kg of ammonium persulfate at one time, stir, and react in a closed manner at 40° C. for 1 h.

[0041] (3) Keep the mixing system of step (2) at 40°C, drop the remaining pre-emulsion therein, and then add dropwise the aqueous solution of ammonium persulfate (mixed 0.14kg ammonium persulfate and 1kg deionized water) ), the two-step dropwise addition takes a total of 1.0h, and after the dropwise addition, keep the mixture under airtight insulation at 50°C for 2.5h.

[0042] (4) Cool the mixing system of step (3) to room temperature, add ammonia water with a mass concentration of 1% to adjust the pH v...

Embodiment 2

[0045] (1) Add 0.05kg of K12, 1kg of polyvinyl alcohol, 8kg of n-hexane, 8kg of methyl chlorosilane, 5kg of methyl methacrylate, 4kg of butyl acrylate, 1kg of KH570 and 25kg of water into the reaction vessel, and stir evenly to obtain a pre-emulsion .

[0046] (2) Take a pre-emulsion with 30% of the total mass of the pre-emulsion obtained in step (1), quickly add 0.16 kg of ammonium persulfate at one time, stir, and react in a closed manner at 50° C. for 0.5 h.

[0047] (3) The mixing system of step (2) is kept at 50 DEG C, and the remaining pre-emulsion is added dropwise thereto, and then the aqueous solution of ammonium persulfate is added dropwise (0.32kg ammonium persulfate is mixed with 0.5kg deionized water to into), the two-step dropwise addition takes a total of 1.5h, and after the dropwise addition is completed, it is sealed and kept at 55°C for 1.5h.

[0048] (4) Cool the mixing system of step (3) to room temperature, add ammonia water with a mass concentration of 1...

Embodiment 3

[0051] (1) Add 0.04kg of K12, 0.6kg of polyvinyl alcohol, 6kg of n-hexane, 7kg of vinyltrichlorosilane, 4kg of methyl methacrylate, 3kg of butyl acrylate, 0.5kg of KH570 and 20kg of water into the reaction vessel, and stir well Get a pre-emulsion.

[0052] (2) Take a pre-emulsion with 30% of the total mass of the pre-emulsion obtained in step (1), quickly add 0.1 kg of ammonium persulfate at one time, stir, and react in a closed manner at 45° C. for 0.7 h.

[0053] (3) Keep the mixing system of step (2) at 45°C, add the remaining pre-emulsion successively to it, and then add the aqueous solution of ammonium persulfate (mixed 0.3kg ammonium persulfate and 1kg deionized water) ), the two-step dropwise addition takes a total of 1.0h, and after the dropwise addition, it is kept at 50°C for 2.0h in an airtight manner.

[0054] (4) Cool the mixing system of step (3) to room temperature, add ammonia water with a mass concentration of 1% to adjust the pH value of the system to 6.5 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com