Molecular sieve encapsulated rhodium heterogeneous core-shell catalyst for olefin hydroformylation, and catalytic method thereof

A heterogeneous catalyst, catalyst technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as difficult industrial production, achieve easy recycling, improve sintering resistance and catalytic activity, High temperature sintering stability and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

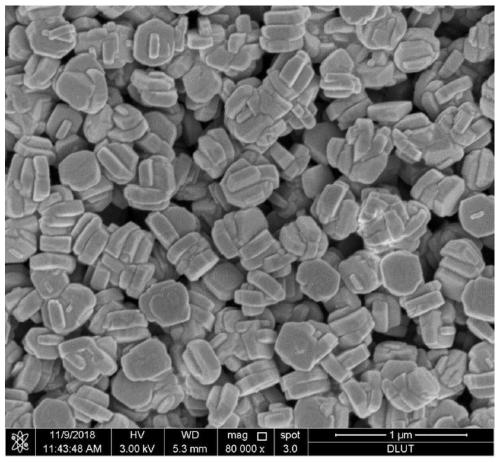

[0029] (1) Thiolation treatment of S-1 seed crystal

[0030] Take 0.2 g of self-made S-1 seed crystals with a size of about 150 nm, disperse them into 20 mL of ethanol, and add 2.86 mmol of 3-mercaptopropyltrimethoxysilane dropwise. The seed crystal suspension was stirred at 60° C. for 6 h to obtain S-1 seed crystals that had undergone mercaptolation treatment. The self-made S-1 seed crystal in this step can be prepared by any method known in the art, such as the preparation of the S-1 seed crystal mentioned in Chinese invention patent application CN107442155A.

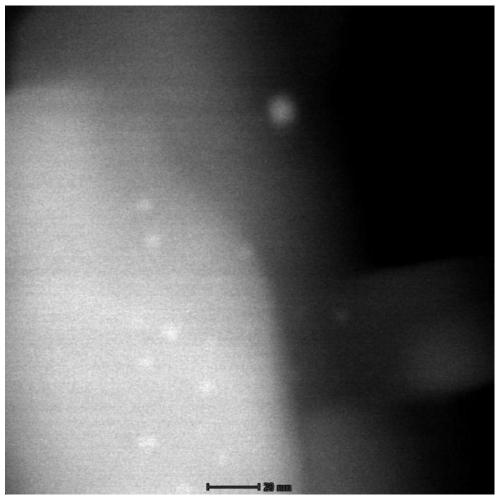

[0031] (2) Loading of rhodium precursor solution

[0032] Disperse the mercapto-treated S-1 seed crystals obtained in step (1) into 15 mL of deionized water to obtain mixture A; take 0.005 g of RhCl 3 The powder was dissolved in 5mL deionized water to obtain solution B. Add B into A, stir at room temperature for 4h, and obtain S-1 seed crystals supported by rhodium ions (Rh 3+ / S-1).

[0033] (3) Rh 3+ / S-1 epit...

Embodiment 2

[0038] (1) The thiolation treatment of the S-1 seed crystal is the same as that in Example 1.

[0039] (2) The loading of the rhodium precursor solution is the same as in Example 1.

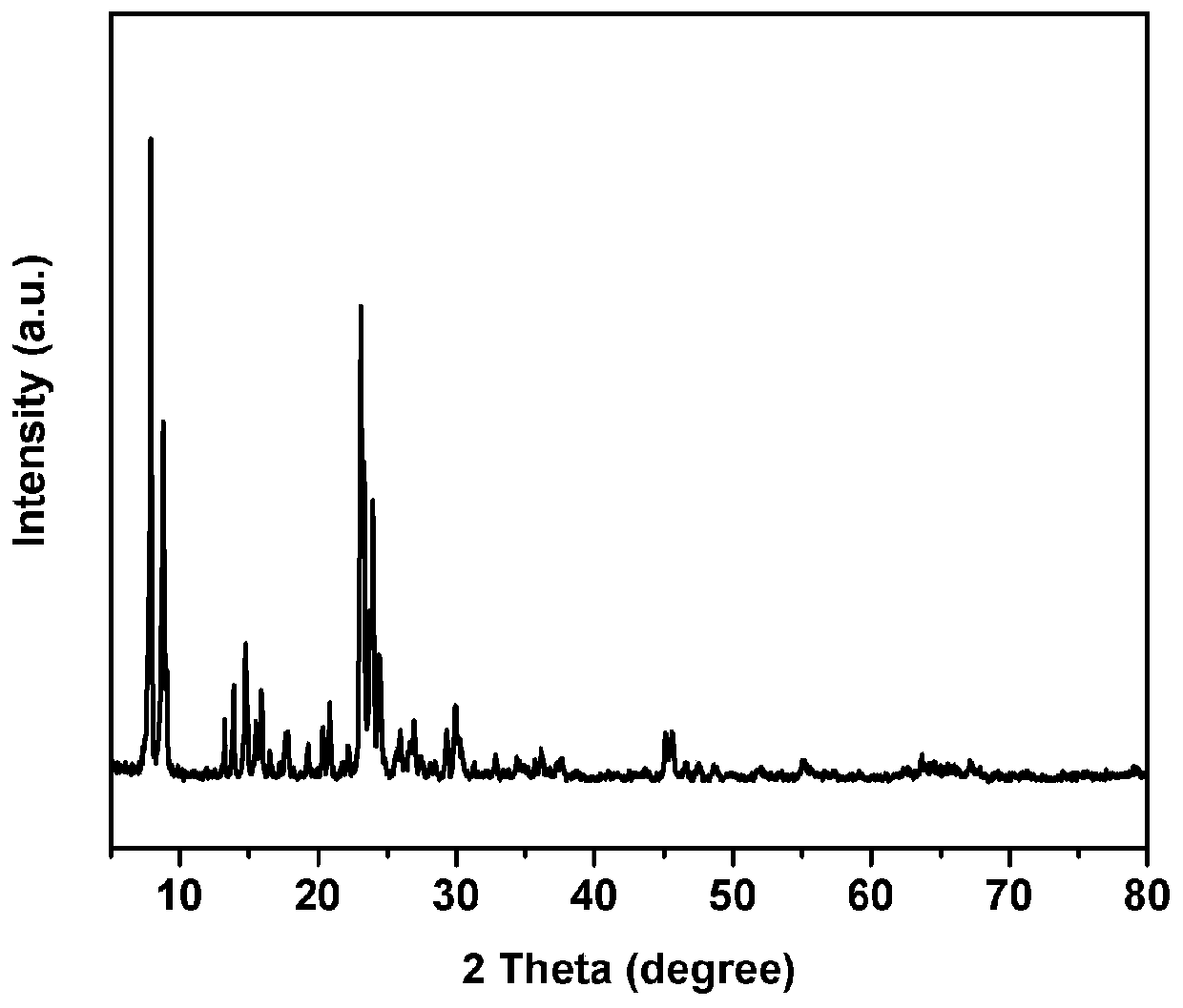

[0040] (3) Rh 3+ / S-1 epitaxial growth of S-1 shell

[0041] According to TEOS:TPAOH:H 2 The molar ratio of O=40:10:20000 is used to prepare the S-1 shell layer synthesis solution, and the Rh obtained in step (2) 3+ / S-1 seed crystals were added to the synthesis solution and aged for 2 hours at room temperature. After the aging, the synthetic solution was put into a synthesis kettle with a polytetrafluoroethylene liner, and hydrothermally synthesized at 170° C. for 24 hours in a rotary oven at a speed of 3 r / min. After the synthesis is completed, the mixed liquid in the polytetrafluoroethylene lining is centrifuged in a high-speed centrifuge, and the solid product is taken for drying, and roasted in a muffle furnace at 550 ° C for 6 hours, and finally the S-1 zeolite molecular sieve encapsula...

Embodiment 3

[0045] (1) The thiolation treatment of the S-1 seed crystal is the same as that in Example 1.

[0046] (2) The loading of the rhodium precursor solution is the same as in Example 1.

[0047] (3) Rh 3+ The / S-1 epitaxially grown S-1 shell is the same as in Example 2.

[0048] (4) Application of Rh@S-1 core-shell catalyst in hydroformylation process

[0049] Weigh the Rh@S-1 catalyst and reactants with a molar ratio of metal rhodium and 1-hexene of 1:6400, and disperse them in 8 mL of toluene solvent. CO and H in a 1:1 volume ratio 2 As a reaction gas, after purging the reaction device 4 times, the reaction was carried out at 80° C. for 12 hours under a pressure of 5 MPa. After the reaction, the catalyst and feed liquid are centrifuged, and the solid catalyst is dried and recovered, and the liquid product is detected by gas chromatography (chromatographic column: SE-30, FID).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com