Method for catalyzing propylene epoxidation in micro-channel by utilizing metalloporphyrin loaded titanium silicate molecular sieve

A titanium-silicon molecular sieve and metalloporphyrin technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of increasing the input cost of propylene oxide production, restricting the industrialization process, and high explosion-proof requirements, and achieves Screening and optimization of process conditions, high reaction selectivity and safety, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

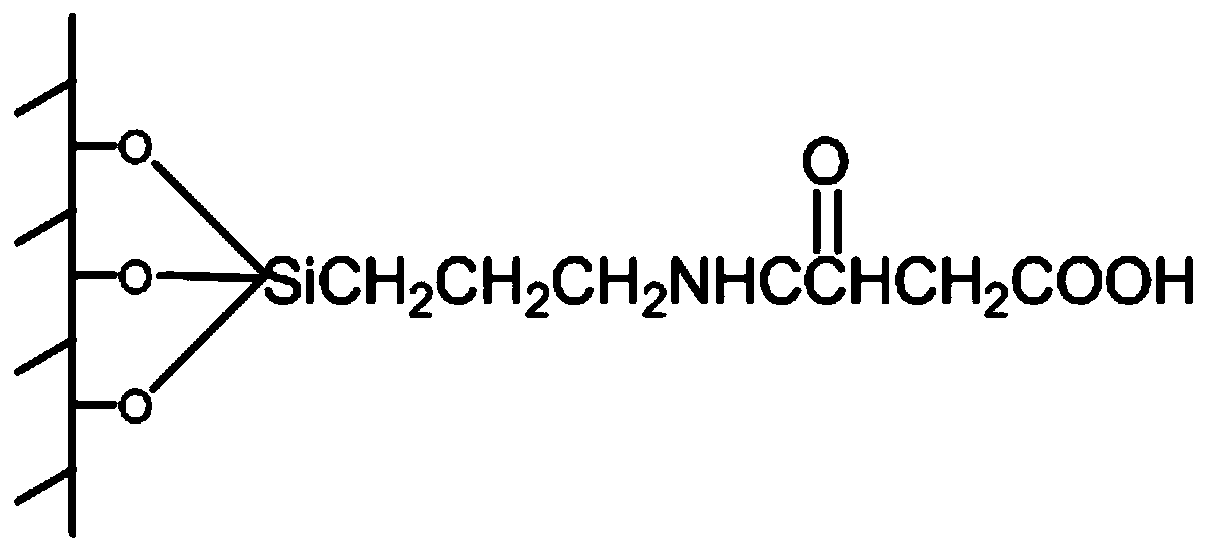

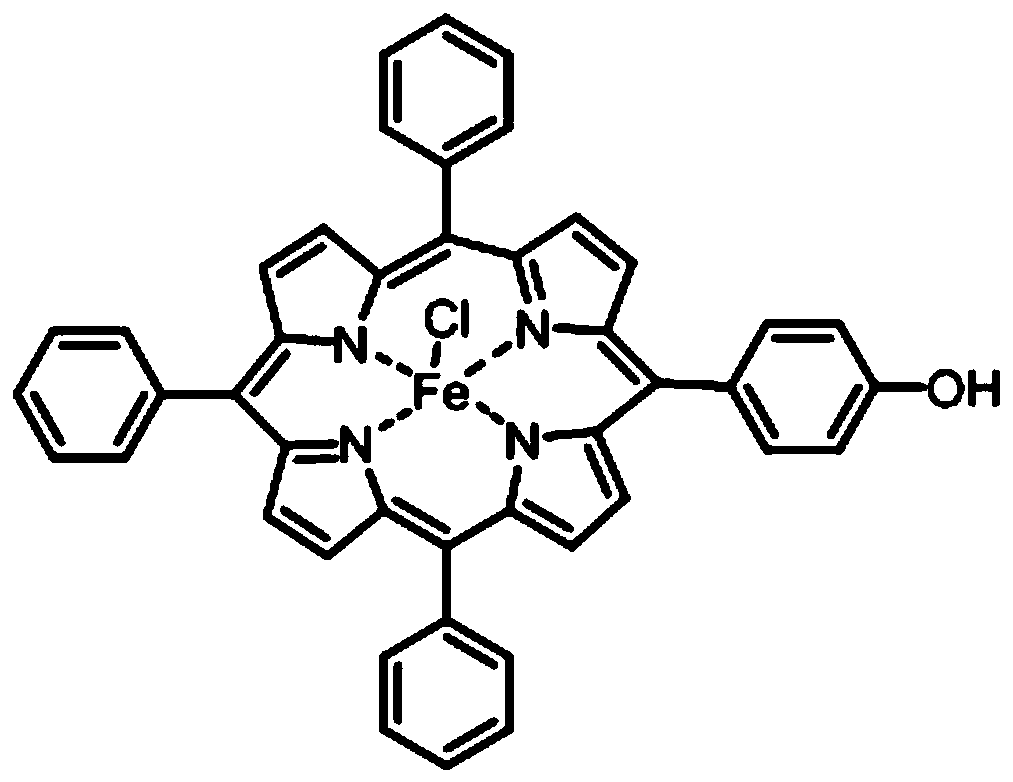

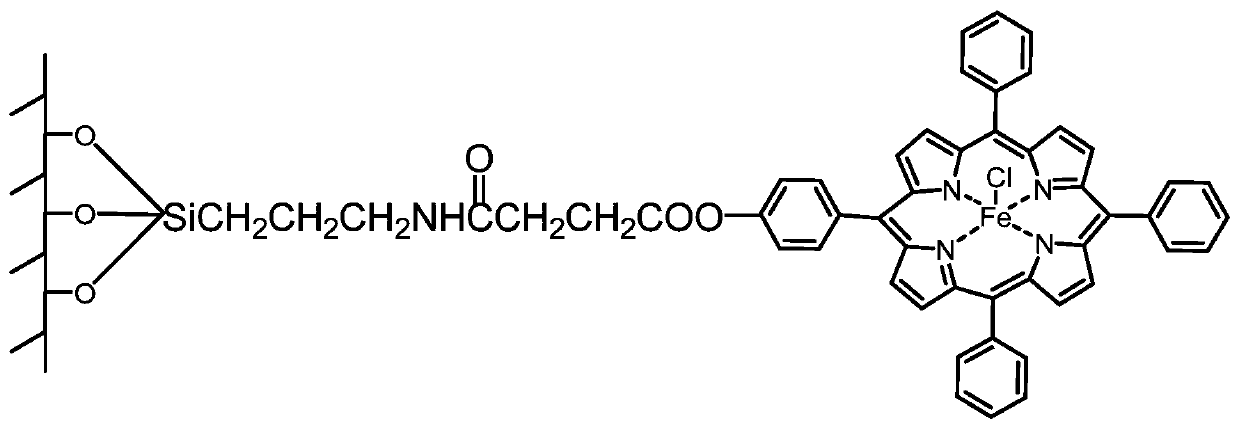

[0041] Weigh 1.2g TS-1, add 100mL 0.1mol / L chloroform solution of 3-aminopropyltrimethoxysilane and mix, N 2 Stir mechanically at room temperature for 12 hours during protection, filter, and wash with chloroform and dichloromethane several times until the washing liquid has no characteristic UV-visible absorption peak of porphyrin, and dry to obtain modified TS-1*; weigh 1.3g TS-1*, add dry 10mL pyridine, 40mg DMAP, 2mL triethylamine, 6g succinic anhydride, mechanically stir at room temperature for 20h, filter, wash with pyridine, dichloromethane and diethyl ether successively, and dry to obtain the new catalyst Ⅰ, which structure is like figure 1 shown.

[0042] Measure 100mL of propionic acid into a flask, heat and control the temperature of the oil bath to about 140°C, make the propionic acid slightly boil, add 1.17g of p-hydroxybenzaldehyde (9.57mmol), 2.67mL of benzaldehyde (26.3mmol) in sequence, and stir to make it Dissolve, and drop 2.43mL double-distilled pyrrole (3...

Embodiment 2

[0046] Weigh 1.2g TS-1, add 100mL 0.1mol / L chloroform solution of 3-aminopropyltrimethoxysilane and mix, N 2 Stir mechanically at room temperature for 12 hours during protection, filter, and wash with chloroform and dichloromethane several times until the washing liquid has no characteristic UV-visible absorption peak of porphyrin, and dry to obtain modified TS-1*; weigh 1.3g TS-1*, add dry 10mL pyridine, 40mg DMAP, 2mL triethylamine, 6g succinic anhydride, mechanically stir at room temperature for 20h, filter, wash with pyridine, dichloromethane and diethyl ether successively, and dry to obtain the new catalyst Ⅰ.

[0047] Measure 100mL of propionic acid into a flask, heat and control the temperature of the oil bath to about 140°C, make the propionic acid slightly boil, add 1.17g of p-hydroxybenzaldehyde (9.57mmol), 2.67mL of benzaldehyde (26.3mmol) in sequence, and stir to make it Dissolve, and drop 3.02mL double-distilled pyrrole (45mmol) in 5 minutes in the way of constant...

Embodiment 3

[0051] Weigh 1.2g TS-1, add 100mL 0.1mol / L chloroform solution of 3-aminopropyltrimethoxysilane and mix, N 2 Stir mechanically at room temperature for 12 hours during protection, filter, and wash with chloroform and dichloromethane several times until the washing liquid has no characteristic UV-visible absorption peak of porphyrin, and dry to obtain modified TS-1*; weigh 1.3g TS-1*, add dry 10mL pyridine, 40mg DMAP, 2mL triethylamine, 6g succinic anhydride, mechanically stir at room temperature for 20h, filter, wash with pyridine, dichloromethane and diethyl ether successively, and dry to obtain the new catalyst Ⅰ.

[0052] Measure 100mL of propionic acid into a flask, heat and control the temperature of the oil bath to about 140°C, make the propionic acid slightly boil, add 1.17g of p-hydroxybenzaldehyde (9.57mmol), 2.67mL of benzaldehyde (26.3mmol) in sequence, and stir to make it Dissolve, and drop 2.43mL double-distilled pyrrole (35mmol) in 5 minutes in the way of constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com