High-performance polyisatin aromatic hydrocarbon with long side chain ammonium salt, anion exchange membrane and preparation method thereof, and preparation method and application of anion exchange membrane

A technology of polyisatin arene and isatin arene, which is applied in the field of polyisatin arene and its anion exchange membrane and its preparation, can solve the problems of poor chemical stability, low conductivity, and low fuel cell performance, and achieve high alkali resistance Effects of properties, antioxidation, and high ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

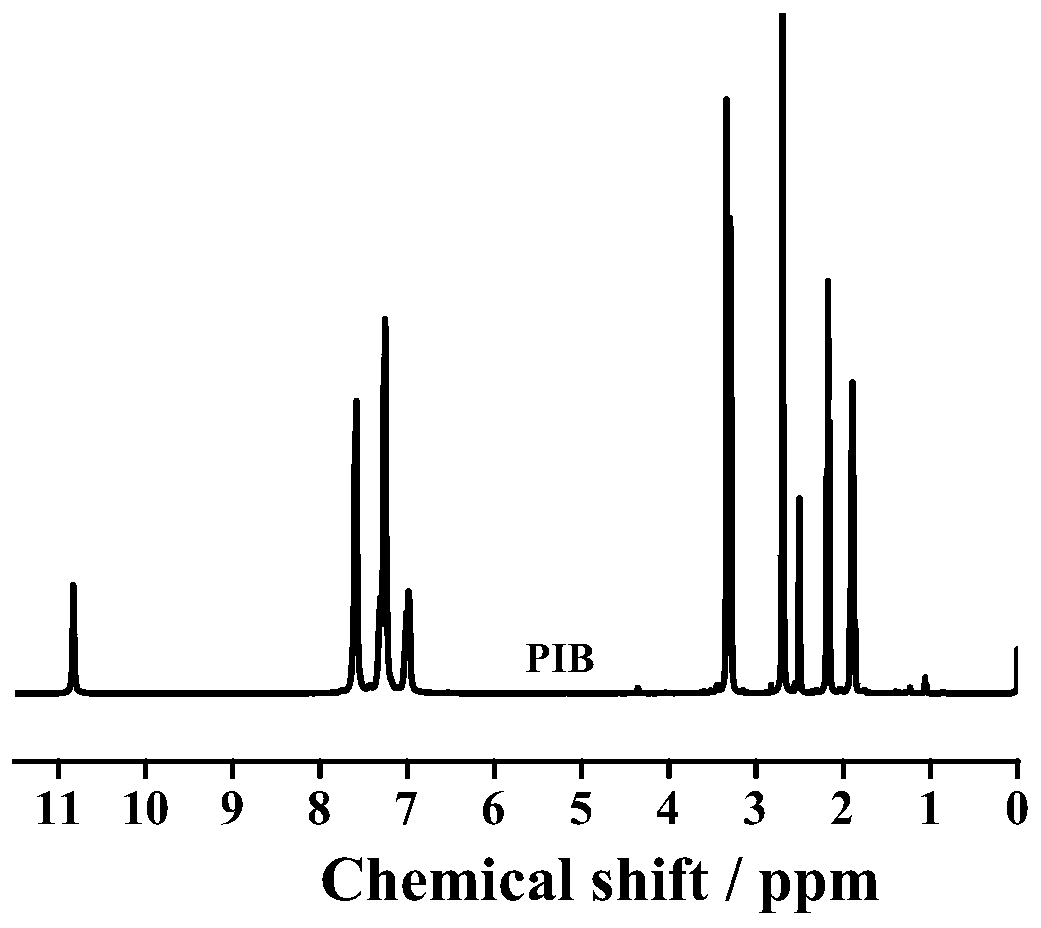

Image

Examples

preparation example Construction

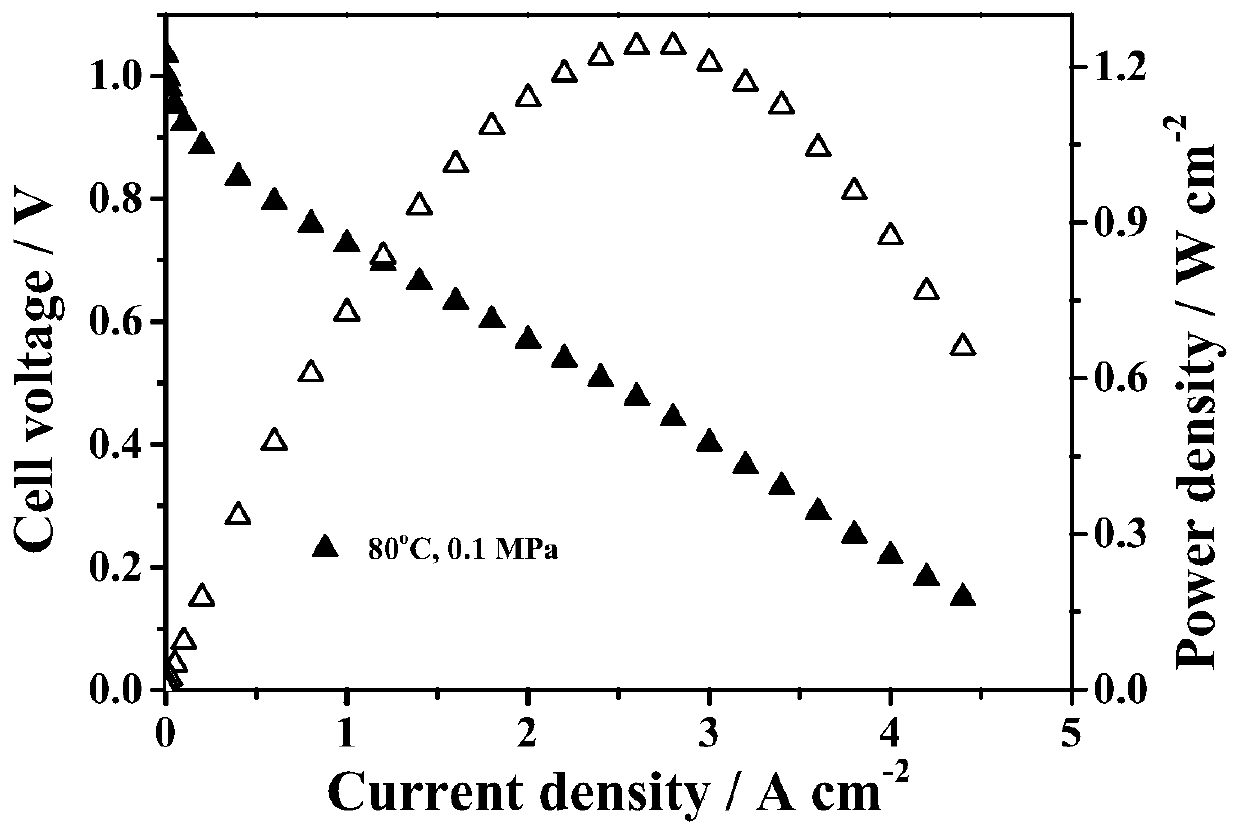

[0060] Preparation of fuel cell membrane electrode: the two sides of the polyisatin anion membrane with long side chain ammonium salt are evenly sprayed with 60% by mass of Pt / C catalyst, and polypiperidine aromatic polymer is used as ionic liquid to obtain Ionic membrane coated with a catalyst layer. Place it in 1M KOH solution for 28 hours to fully exchange hydroxide ions. Wash away the residual hydroxide ions on the surface with deionized water, and form a membrane electrode with the porous carbon paper and the prepared ionic membrane coated with a catalyst coating. The area of the membrane electrode is 4cm 2 , assemble the membrane electrode into a fuel cell.

[0061] Fuel cell performance test: the instrument used is produced by Scribner Associates Co. of the United States, the instrument model is 850e multi-range fuel cell test system, and the test is performed in current mode. The test condition is H 2 and O 2 Fully humidified, test temperature 60°C, 80°C, H 2 an...

Embodiment 1

[0066] Synthesis of long-chain trimethylammonium salt: Dissolve 1mol 1,6-dibromohexane in 1300mL acetone, feed trimethylamine, and react at 30°C for 48h. A white solid was obtained by filtration, washed repeatedly with acetone, and dried in vacuo to obtain a long-chain trimethylammonium salt.

[0067] Synthesis of polyisatin biphenyl: Take 10g of isatin and 60mL of trifluoroacetic acid into the reactor, add 8g of biphenyl, stir and dissolve at about 0°C. Add 40mL of trifluoromethanesulfonic acid and react at room temperature for 14h. Pour the viscous polymer into a large amount of Na 2 CO 3 The aqueous solution is fully washed with deionized water, filtered, and vacuum-dried to obtain polyisatin biphenyl. Dissolving the polymer with an appropriate amount of N-methylacetamide, precipitating in deionized water, washing with water, filtering, and drying in vacuum to obtain refined polyisatin biphenyl.

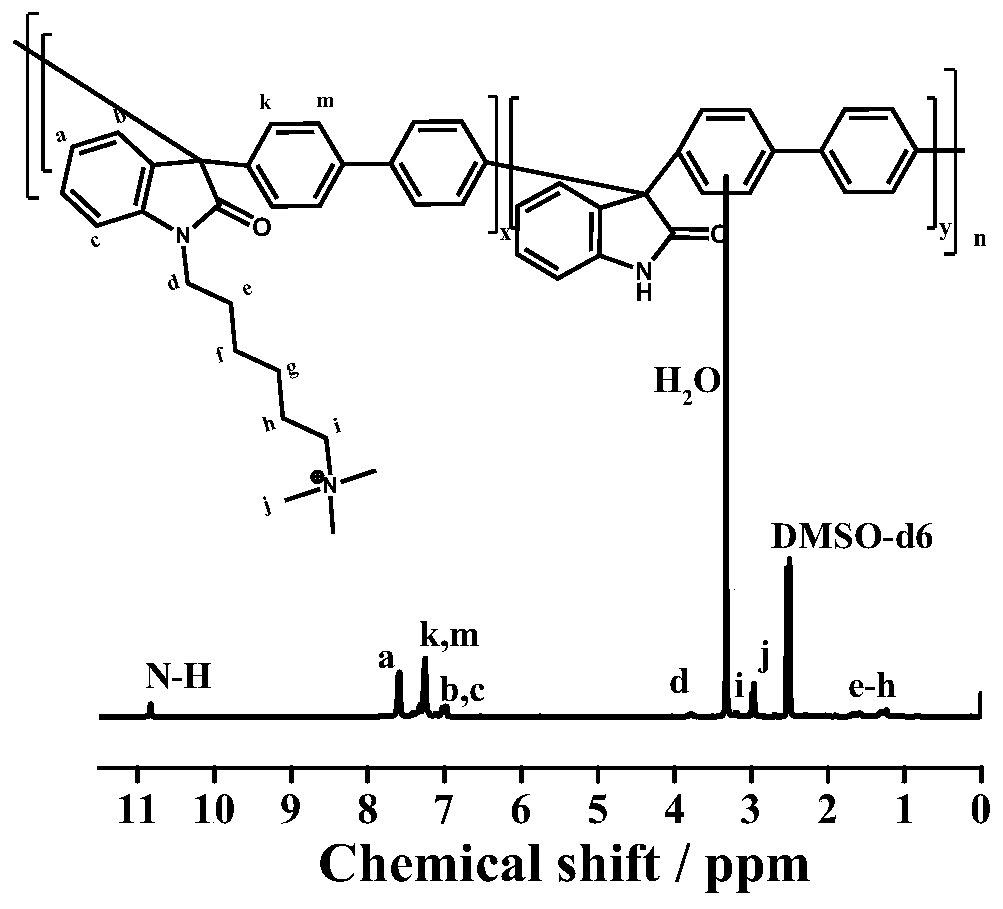

[0068] Synthesis of polyisatin biphenyl with long side chain trimethylamm...

Embodiment 2

[0076] Synthesis of long-chain N-methylpyrrolidine salt: Dissolve 1mol 1,4-dibromobutane in 1000mL acetone, add N-methylpyrrolidine, and react at 30°C for 48h. A white solid was obtained by filtration, washed repeatedly with acetone, and dried in vacuo to obtain a long-chain N-methylpyrrolidinium salt.

[0077] Synthesis of polyisatin m-terphenyl: Take 10g of isatin and 40mL of trifluoroacetic acid into the reactor, add 10g of m-terphenyl, stir and dissolve at about 0°C. Add 45mL of trifluoromethanesulfonic acid and react at room temperature for 8h. Pour the viscous polymer into a large amount of NaHCO 3 The aqueous solution is fully washed with deionized water, filtered, and vacuum-dried to obtain polyisatin m-terphenyl. Dissolving the polymer with an appropriate amount of dimethyl sulfoxide, precipitating in deionized water, washing with water, filtering, and drying in vacuum to obtain refined polyisatin m-terphenyl.

[0078] Synthesis of polyisatin m-terphenyl with long ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com