A kind of silk fibroin/graphene composite conductive film and preparation method thereof

A graphene composite and conductive film technology, applied in the preparation of silk fibroin/graphene composite conductive film, in the field of silk fibroin/graphene composite conductive film, can solve the complex preparation process, poor product conductivity, chemical dosage major problems, to achieve the effect of simple and environmentally friendly method, non-toxic preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 silk fibroin solution and graphene slurry

[0034] Take 80g silkworm raw silk and put it into 4000ml sodium carbonate solution with a concentration of 0.06%, boil three times at 98-100°C, use deionized water for each treatment for 30min each time, remove the sericin in the raw silk, wash and pull After loosening, place it in an oven at 60°C to dry to obtain pure silk fiber. Dissolve the dried silk fiber in 9.3M lithium bromide solution at 60°C, the bath ratio is 3:20, and the dissolution time is about 1 hour. After it cools down, take it out and put it into a dialysis bag and place it in deionized water for dialysis for 3 days , to obtain a silk fibroin solution, and put it in a 4°C refrigerator for later use. When in use, the concentration of the silk fibroin solution is adjusted to 5-50 mg / mL with deionized water.

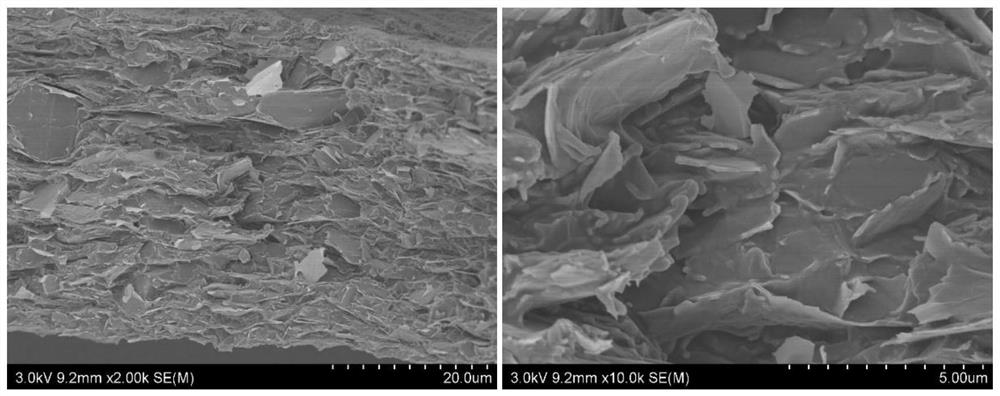

[0035] The graphene slurry is prepared by using a liquid phase exfoliation method and using N-methylpyrrolidone as a sol...

Embodiment 2

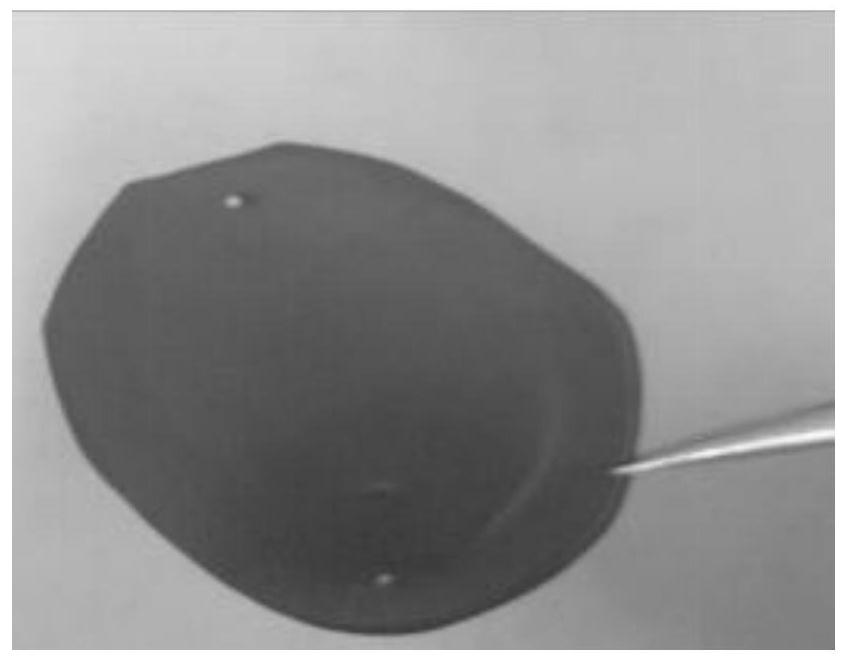

[0036] The preparation of embodiment 2 silk fibroin / graphene composite conductive film

[0037] (1) Dispersion solution preparation: Take 1 g of polyvinyl alcohol with a degree of polymerization of 1000 and a degree of alcoholysis of 99%, and dissolve it in 1000 mL of deionized water to obtain an aqueous solution of polyvinyl alcohol (PVA) with a concentration of 1 mg / mL.

[0038] (2) Preparation of graphene dispersion: the graphene slurry prepared in Example 1 is added in the polyvinyl alcohol aqueous solution of step (1), the mass ratio of control graphene and PVA is 1:1, after mixing, add dialysis The bag was dialyzed with running water for 10 hours to remove N-methylpyrrolidone and obtain a graphene aqueous dispersion. The specification of the dialysis bag used in this embodiment is 8000-14000Da.

[0039](3) Preparation of silk fibroin / graphene mixed solution: Slowly add the graphene aqueous dispersion in step (2) to the silk fibroin solution prepared in Example 1, stir a...

Embodiment 3

[0042] The preparation of embodiment 3 silk fibroin / graphene composite conductive film

[0043] (1) Dispersion solution preparation: Take 0.2 g of polyvinyl alcohol with a degree of polymerization of 800 and a degree of alcoholysis of 99%, and dissolve it in 1000 mL of deionized water to obtain an aqueous solution of polyvinyl alcohol (PVA) with a concentration of 0.2 mg / mL.

[0044] (2) Preparation of graphene dispersion: the graphene slurry prepared in Example 1 is added in the polyvinyl alcohol aqueous solution of step (1), the mass ratio of control graphene and PVA is 5:1, add dialysis after mixing The bag was dialyzed with running water for 8 hours to remove N-methylpyrrolidone and obtain a graphene aqueous dispersion. The specification of the dialysis bag used in this embodiment is 8000-14000Da.

[0045] (3) Preparation of silk fibroin / graphene mixed solution: Slowly add the graphene aqueous dispersion in step (2) to the silk fibroin solution prepared in Example 1, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com