W-doped and modified high-nickel ternary positive electrode material

A cathode material, high nickel technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as mixing, phase transition, battery capacity structure damage, etc., to achieve improved rate performance, simple synthesis method, and reduced charge transfer resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

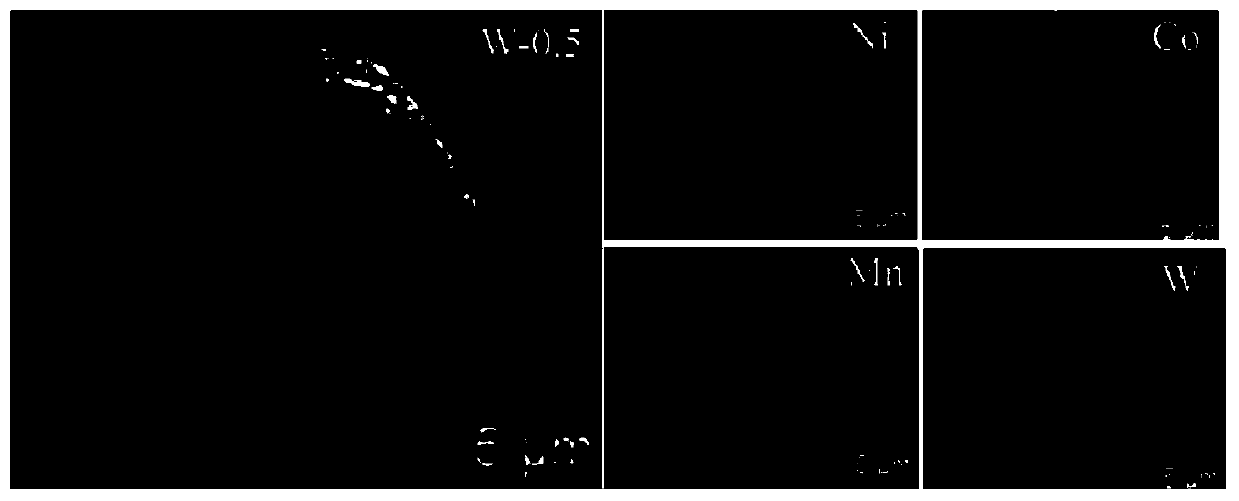

[0035] LiOH·H 2 O was added to the mortar for dry grinding for 4min, and then the nickel-cobalt-manganese oxide precursor (Ni 0.8 co 0.1 mn 0.1 (OH) 2 ) and tungsten trioxide were mixed evenly, and after dry milling for 10 minutes, ethanol was added to submerge the mixture of nickel-cobalt-manganese oxide precursor and tungsten trioxide, and wet milling was carried out for 30 minutes so as to mix more uniformly to obtain a solid powder; wherein LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of tungsten trioxide is 1.05:1, and the amount of tungsten trioxide added is Ni 0.8 co 0.1 mn 0.1 (OH) 2 0.5% of mass. The solid powder is calcined in an oxygen atmosphere, first pre-calcined at 455°C for 4 hours, then heated to 700°C for 18 hours, and the heating rate is 3°C / min in the pre-calcining stage and the calcining stage, and the tube furnace is cooled Next, a W-doped modified high-nickel ternary cathode material is obtained, which is denoted as W-0.5.

[0...

Embodiment 2

[0043] LiOH·H 2 O was added to dry grinding in a mortar, and then nickel-cobalt-manganese oxide precursor (Ni 0.8 co 0.1 mn 0.1 (OH) 2 ) and tungsten trioxide were mixed uniformly, and after dry milling for 20 minutes, ethanol was added to submerge the mixture of nickel-cobalt-manganese oxide precursor and tungsten trioxide, and wet milling was carried out for 30 minutes so as to mix more uniformly to obtain a solid powder; wherein LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of tungsten trioxide is 1.05:1, and the amount of tungsten trioxide added is Ni 0.8 co 0.1 mn 0.1 (OH) 2 1% of mass. The solid powder is calcined in an oxygen atmosphere. First, it is pre-calcined at 500°C for 5 hours, and then heated to 780°C for 15 hours. Next, a W-doped modified high-nickel ternary cathode material is obtained, which is denoted as W-1.

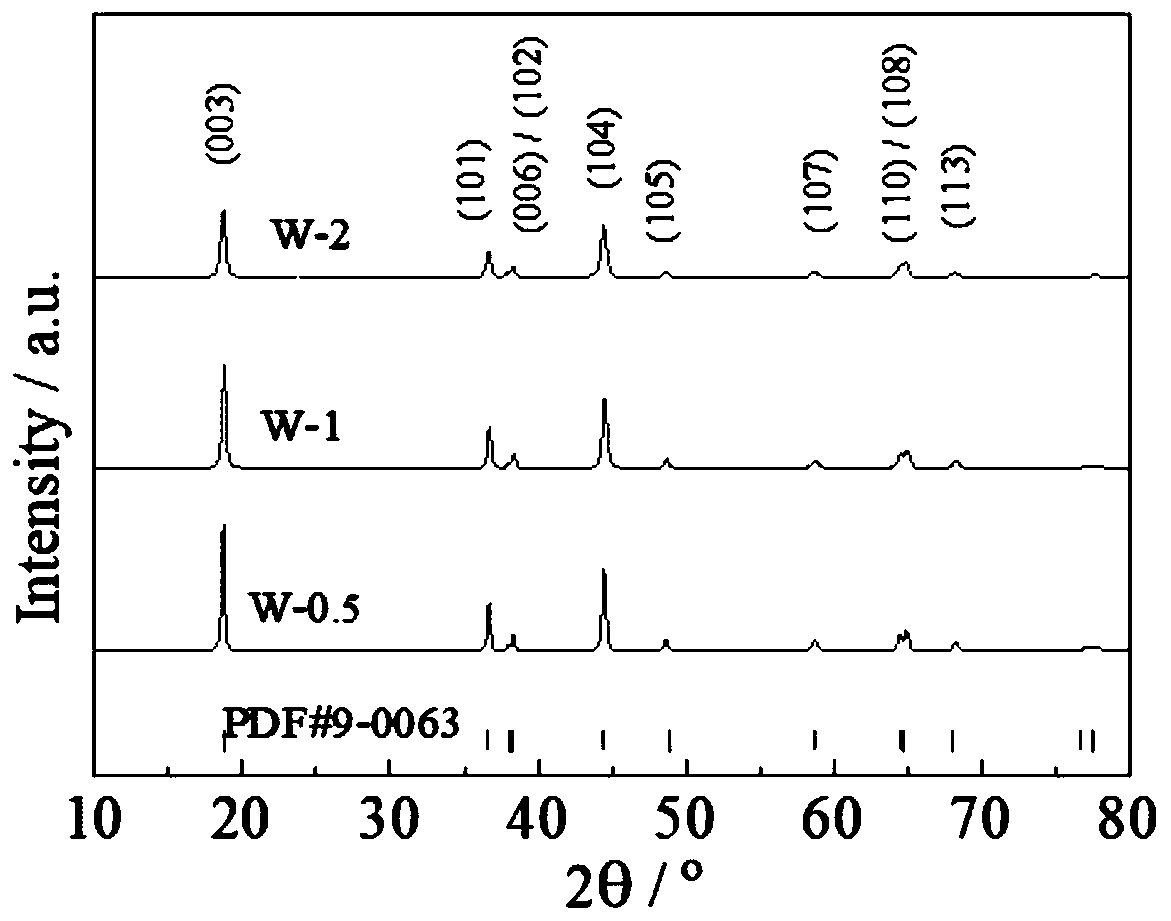

[0044] The XRD test result of final product is as figure 1 As shown, the final product prepared in this example does not c...

Embodiment 3

[0049] LiOH·H 2 O was added to dry grinding in a mortar, and then nickel-cobalt-manganese oxide precursor (Ni 0.8 co 0.1 mn 0.1 (OH) 2 ) and tungsten trioxide were mixed uniformly, and after dry milling for 30 minutes, ethanol was added to submerge the mixture of nickel-cobalt-manganese oxide precursor and tungsten trioxide, and wet milling was carried out for 40 minutes so as to mix more uniformly to obtain a solid powder; wherein LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of tungsten trioxide is 1.05:1, and the amount of tungsten trioxide added is Ni 0.8 co 0.1 mn 0.1 (OH) 2 2% of mass. The solid powder is calcined in an oxygen atmosphere. First, it is pre-calcined at 550°C for 6 hours, and then heated to 850°C for 18 hours. The heating rate of the pre-calcination stage and the calcination stage is 5°C / min. Next, a W-doped modified high-nickel ternary cathode material is obtained, which is denoted as W-2.

[0050] The XRD test result of final pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com