Porous bone repair stent material and preparation method thereof

A scaffold material and porous bone technology, applied in the field of biomedical composite materials, can solve the problems of poor mechanical properties of bone scaffold materials, affect biocompatibility, insoluble in water, etc., and achieve high toughness strength and good biocompatibility. , Reduce the effect of process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]In a 100mL beaker, dissolve 5g of sodium oleate in 15mL of ethanol, and add 10mL of an aqueous solution containing 1g of human-like collagen to it, stir well, then add 10mL of 0.25M calcium chloride aqueous solution and 0.15M phosphoric acid 10 mL of sodium aqueous solution was stirred magnetically at room temperature (25° C.) for 2 days, the reaction solution was centrifuged to obtain a precipitate, and the precipitate was washed twice with ethanol to finally obtain sub-nanometer hydroxyapatite.

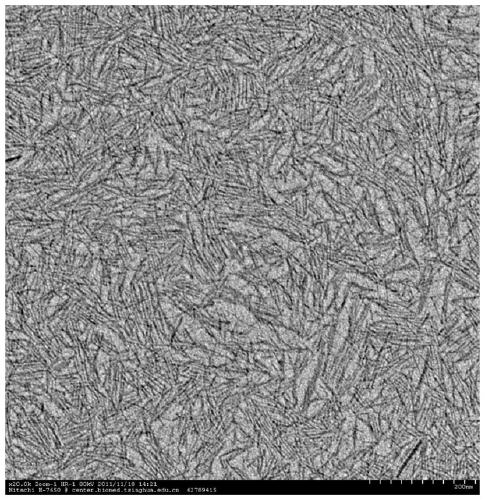

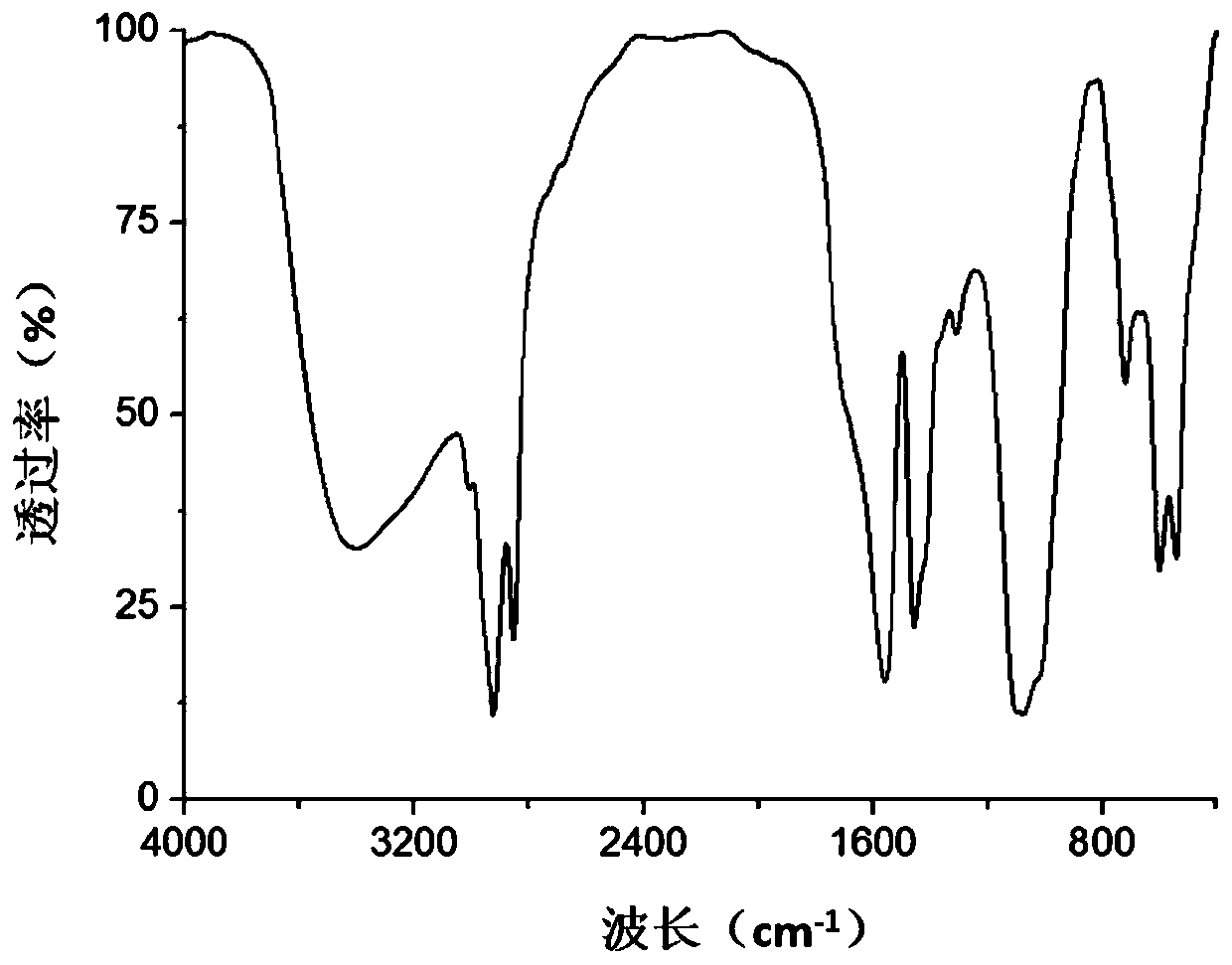

[0040] From figure 1 It can be seen from the figure that the sample prepared in this example is an ultrafine hydroxyapatite subnanowire with a diameter of about 1 nm and a length of about 40 nm to 100 nm; figure 2 It can be seen that the prepared samples are rich in hydroxyl groups and have similar characteristic absorption peaks with hydroxyapatite.

Embodiment 2

[0042] In a 100mL beaker, dissolve 5g of sodium oleate in 10mL of ethanol, and add 10mL of an aqueous solution containing 5g of human-like collagen to it, stir well, then add 10mL of 1.0M calcium chloride aqueous solution and 0.6M phosphoric acid 10 mL of sodium dihydrogen aqueous solution was magnetically stirred at room temperature (20° C.) for 5 days, the reaction solution was centrifuged to obtain a precipitate, and the precipitate was washed with ethanol 3 times to finally obtain sub-nanometer hydroxyapatite.

[0043] The physical and chemical characteristics of the sample prepared in this example are similar to those of the sample in Example 1, which are ultrafine hydroxyapatite subnanowires with a diameter of about 1 nm and a length of about 30 nm to 80 nm.

Embodiment 3

[0045] In a 100mL beaker, dissolve 5g of sodium oleate in 20mL of ethanol, and add 15mL of an aqueous solution containing 3g of human-like collagen to it, stir well, then add 15mL of 0.5M calcium chloride aqueous solution and 0.3M phosphoric acid After 15 mL of disodium hydrogen aqueous solution was magnetically stirred at room temperature (22°C) for 4 days, the reaction solution was centrifuged to obtain a precipitate, and the precipitate was washed with ethanol 3 times to finally obtain subnanometer hydroxyapatite.

[0046] The physical and chemical characteristics of the sample prepared in this example are similar to those of the sample in Example 1, which are ultrafine hydroxyapatite subnanowires with a diameter of about 1 nm and a length of about 30 nm to 100 nm.

[0047] Preparation of porous bone repair scaffold materials:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com