Pesticide wastewater treatment technology

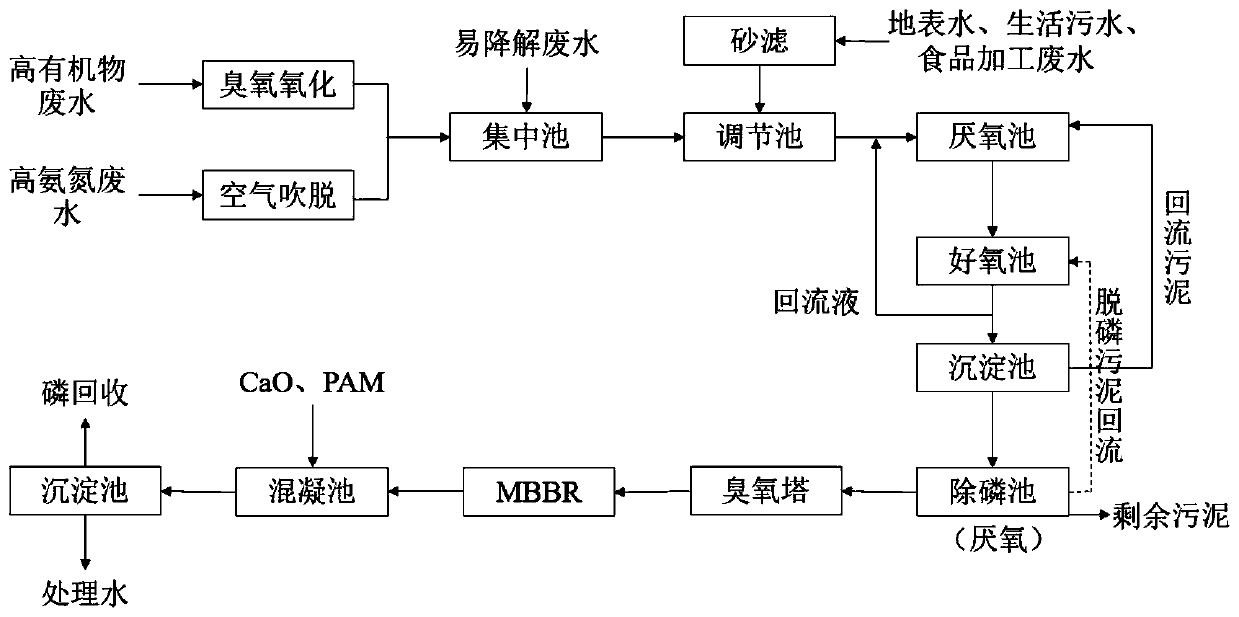

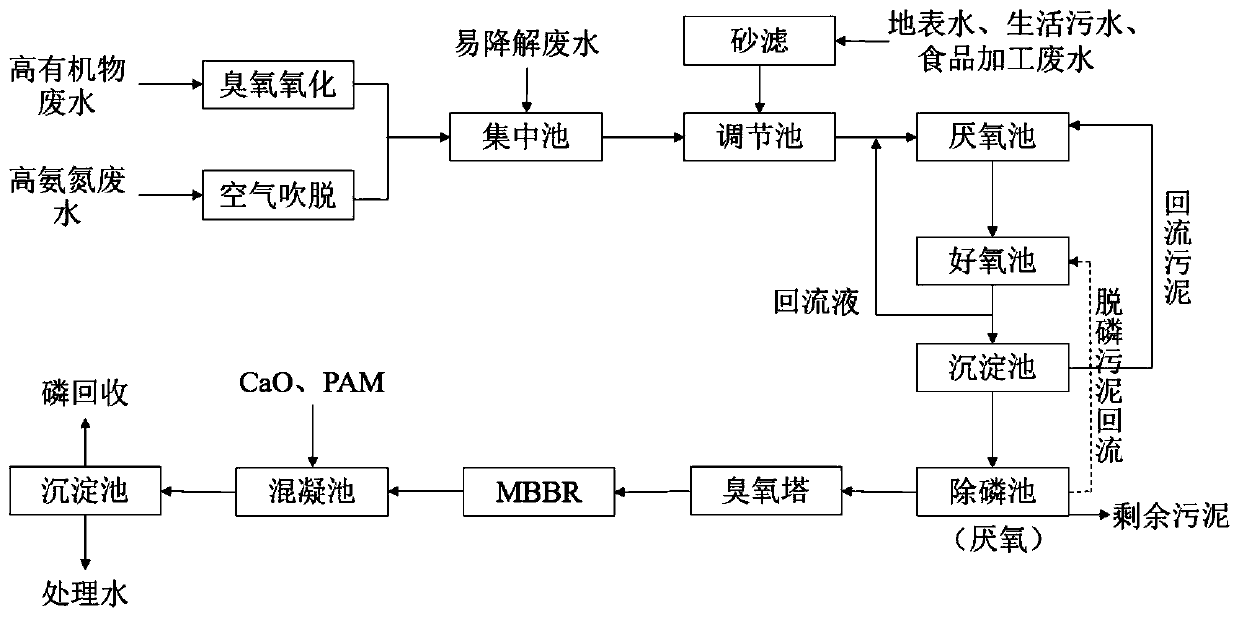

A pesticide wastewater and treatment process technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of affecting sludge activity, increasing operating costs, and increasing internal circulation ratio and other problems, to achieve the effect of reducing energy consumption, reducing water quality fluctuations, and good phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The quality of pesticide wastewater is:

[0050] COD 30000 mg / L NH 3 -N

6000 mg / L TP 5000 mg / L

[0051] (1) Collect the pesticide wastewater to be treated in three different concentration pools according to high-concentration organic wastewater, high-concentration ammonia nitrogen wastewater and easily biodegradable wastewater. Among them, the wastewater with COD greater than 5000mg / L is high-concentration organic wastewater. Wastewater with ammonia nitrogen concentration higher than 500mg / L is high concentration ammonia nitrogen wastewater, BOD 5 Wastewater with / COD greater than 0.45 is easily biodegradable wastewater;

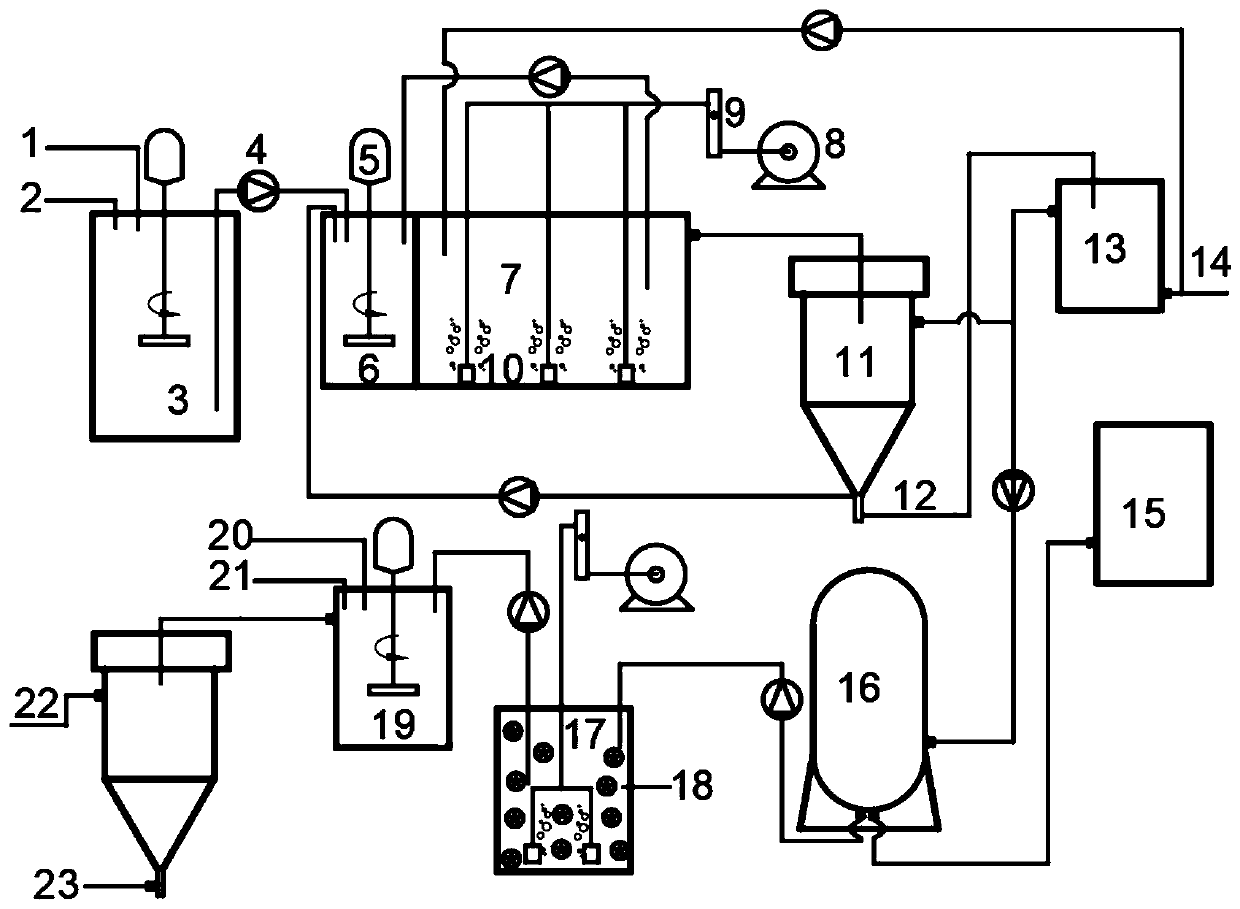

[0052] (2) The amount of ozone added in the high-concentration organic wastewater is 3 grams per milliliter, adding hydrogen peroxide with a molar ratio of 1:2 to oxidize the high-concentration organic wastewater; concentrating the high-concentration ammonia nitrogen wastewater in the pool Adjust the pH of the wa...

Embodiment 2

[0066] The difference between this embodiment and embodiment 1 is:

[0067] COD 15000 mg / L NH 3 -N

[0068] (2) The amount of ozone added in the high-concentration organic wastewater is 3 grams per milliliter, adding hydrogen peroxide with a molar ratio of 1:2 to oxidize the high-concentration organic wastewater; concentrating the high-concentration ammonia nitrogen wastewater in the pool Adjust the pH of the wastewater to 10.5-11.0 with NaOH, and aerate it with air for 24 hours to reduce the concentration of ammonia nitrogen in the pesticide wastewater, and the easily biodegradable wastewater will not be treated;

[0069] (5) the pesticide wastewater in the homogeneous tank and the treated surface water, domestic food processing wastewater 1 are introduced in the regulating tank 3 under the effect of the peristaltic pump 4, the COD of the pesticide wastewater is diluted to 1800mg / L, and the concentration of ammonia nitrogen is determined by Step (2) control,...

Embodiment 3

[0075] The difference between this embodiment and embodiment 1 is:

[0076] COD 20000 mg / L NH 3 -N

4000 mg / L TP 3000 mg / L

[0077] (2) The amount of ozone added in the high-concentration organic wastewater is 3 grams per milliliter, adding hydrogen peroxide with a molar ratio of 1:2 to oxidize the high-concentration organic wastewater; concentrating the high-concentration ammonia nitrogen wastewater in the pool Adjust the pH of the wastewater to 10.5-11.0 with NaOH, and aerate it with air for 24 hours to reduce the concentration of ammonia nitrogen in the pesticide wastewater, and the easily biodegradable wastewater will not be treated;

[0078] (5) the pesticide wastewater in the homogeneous tank and the treated surface water, domestic food processing wastewater 1 are introduced in the regulating tank 3 under the effect of the peristaltic pump 4, the COD of the pesticide wastewater is diluted to 2200mg / L, and the concentration of ammonia n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com