A kind of residual activated sludge drying processing method

A processing method and residual activity technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of limited drying efficiency, reduce drying energy consumption and improve activity , the effect of accelerating dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

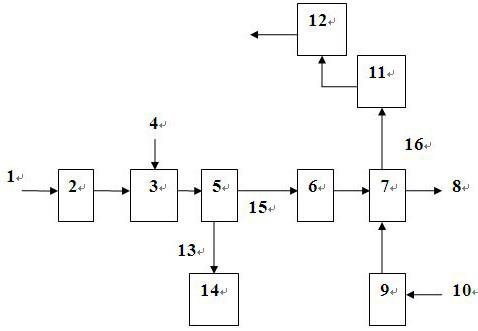

Image

Examples

Embodiment 1

[0029] The specific embodiment of the present invention will be described by taking the excess sludge of a certain sewage treatment plant as an example. Add 200kg of excess sludge with a moisture content of 96.40% to the electrolytic cell, add 2% TS sludge (TS is the total solid content of sludge) sodium perchlorate and 3% TS sludge triphosphate Butyl ester, and after adding 2% polymyxin of TS sludge, acted at 20mA / cm2, 400HZ for 1.5h, the VSS reduction rate of the sludge after breaking the wall was 38.29%, and the SCOD increased by 36.52 times of the original sludge. After the wall is broken, the sludge is subjected to centrifugal dehydration. After dehydration, the moisture content of the sludge is 65.61%. The sewage is discharged into the biochemical unit of the sewage treatment plant for further treatment. After dehydration, the mud cake enters the filter press to be pressed into 4mm strips of sludge and is transported The belt enters the solar multi-layer mesh belt low-te...

Embodiment 2

[0031] Basically the same as Example 1, the difference is that the treatment agent is sodium perchlorate of 0.2% TS sludge and tributyl phosphate of 0.35% TS sludge and colistin of 0.13% TS sludge. The sludge VSS reduction rate was 32.07%, and the SCOD increased 31.79 times of the original sludge. The moisture content of the sludge after wall breaking and dehydration reaches 68.50%, and the moisture content of the remaining sludge after final drying drops to 12.94%.

Embodiment 3

[0033] Basically the same as Example 1, the difference is that the treatment agent is sodium perchlorate of 1%TS sludge and tributyl phosphate of 1.5%TS sludge, polymyxin and 0.5%TS of 0.5%TS sludge The colistin in the sludge, the VSS reduction rate of the sludge after breaking the wall was 42.54%, and the SCOD increased by 40.74 times of the original sludge. The moisture content of the sludge after wall breaking and dehydration reaches 62.47%, and the moisture content of the remaining sludge after final drying drops to 10.76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com