Method for preparing cyclopentane refrigerant

A refrigerant and cyclopentane technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve the problem that cyclopentane and 2,2-dimethylbutane cannot be separated and are not applicable Industrial production, narrow operating range, etc., to achieve the effect of high selectivity, good stability, and low solvent ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

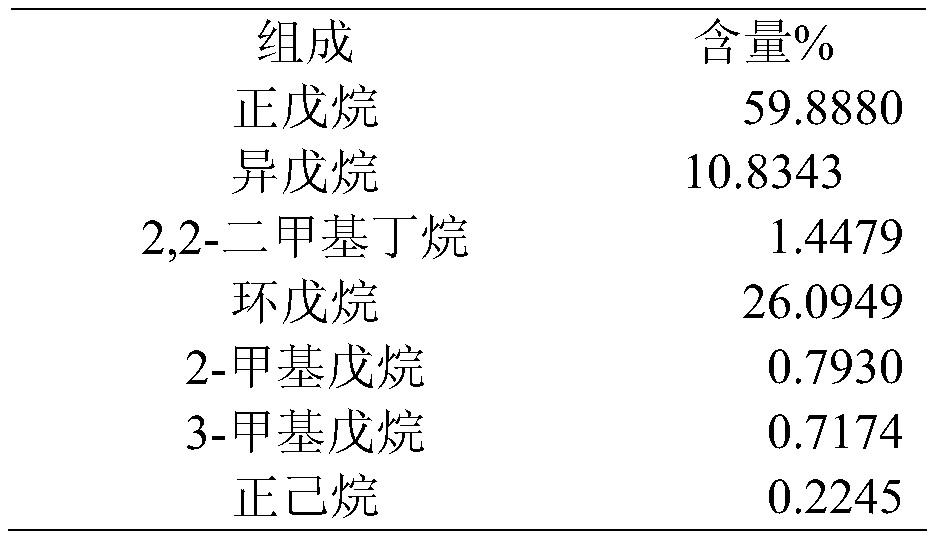

[0018] The composition of raw materials is as follows:

[0019]

[0020] Weigh 1000g of raw oil to remove n-pentane and isopentane components under the conditions of operating pressure of 102KPa, reflux ratio of 4.5, and tower bottom temperature of 65°C, and then remove n-pentane and isopentane components at an operating pressure of 110KPa and a reflux ratio of 12 , under the condition that the temperature at the bottom of the tower is 78°C, the carbon six components are removed, and the main components are a mixture of cyclopentane and 2,2-dimethylbutane, and the purity of cyclopentane is 90.1%; controlled extractive distillation The operating pressure of the tower is 102KPa. Weigh a certain amount of the mixture and acetonitrile to carry out extractive distillation experiment, wherein the mass ratio of the mixture to acetonitrile is 1:6, the reflux ratio is 70, the temperature at the bottom of the tower is 70°C, and the mixture containing cyclopentane is obtained at the bo...

Embodiment 2

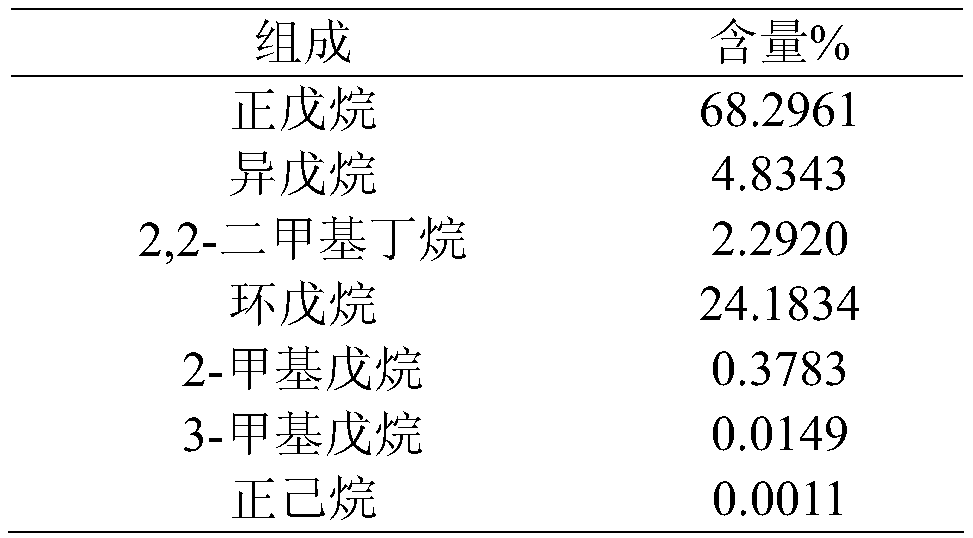

[0022] The composition of raw materials is as follows:

[0023]

[0024] Weigh 1000g of feedstock oil to remove n-pentane and isopentane components under the conditions of operating pressure of 110KPa, reflux ratio of 4, and tower bottom temperature of 68°C, and then remove n-pentane and isopentane components at an operating pressure of 102KPa and a reflux ratio of 9 , under the condition that the temperature at the bottom of the tower is 75°C, the C6 components are removed, and the main components are a mixture of cyclopentane and 2,2-dimethylbutane, and the purity of cyclopentane is 91.2%; controlled extractive distillation The operating pressure of the tower is 115KPa. Weigh a certain amount of the mixture and acetonitrile for extractive distillation experiment, wherein the mass ratio of the mixture to acetonitrile is 1:8, the reflux ratio is 55, the temperature at the bottom of the tower is 78°C, and the mixture containing cyclopentane is obtained at the bottom of the to...

Embodiment 3

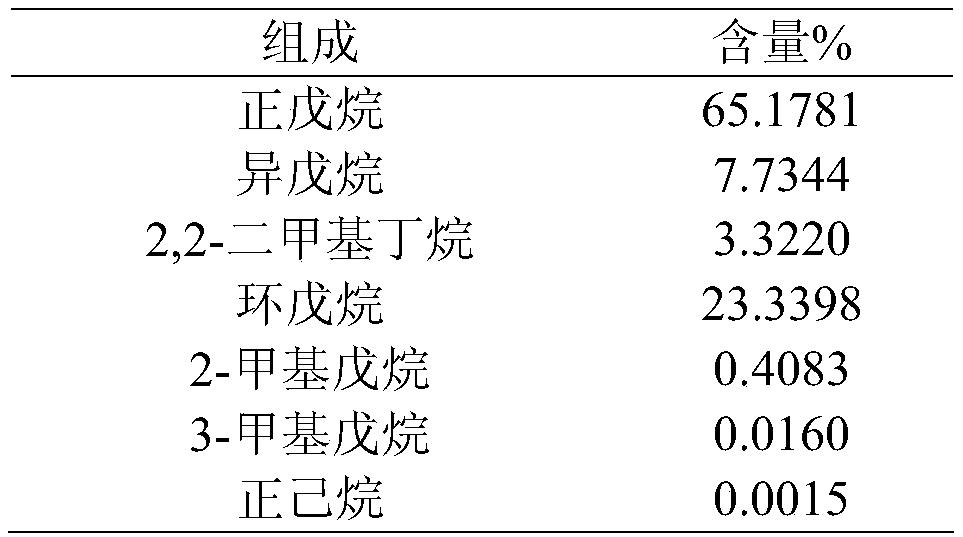

[0026] The composition of raw materials is as follows:

[0027]

[0028] Weigh 1000g of raw oil to remove n-pentane and isopentane components under the conditions of operating pressure of 120KPa, reflux ratio of 5, and tower bottom temperature of 75°C, and then remove n-pentane and isopentane components at an operating pressure of 115KPa and a reflux ratio of 11 , under the condition that the temperature at the bottom of the tower is 80°C, the carbon six components are removed, and the main components are a mixture of cyclopentane and 2,2-dimethylbutane, and the purity of cyclopentane is 92.3%; controlled extractive distillation The operating pressure of the tower is 120KPa. Weigh a certain amount of the mixture and acetonitrile to carry out the extractive distillation experiment, wherein the mass ratio of the mixture to acetonitrile is 1:9, the reflux ratio is 45, the temperature at the bottom of the tower is 80°C, and the mixture containing cyclopentane is obtained at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com