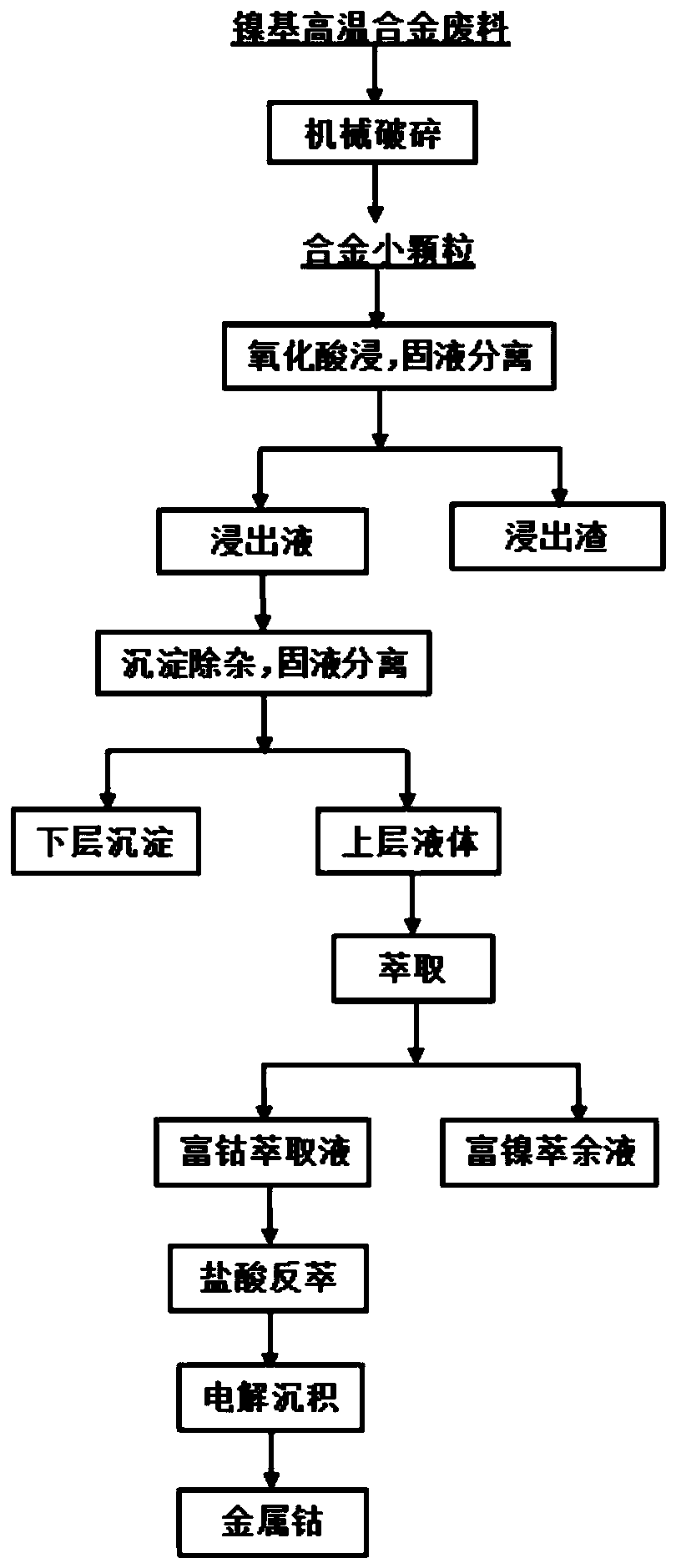

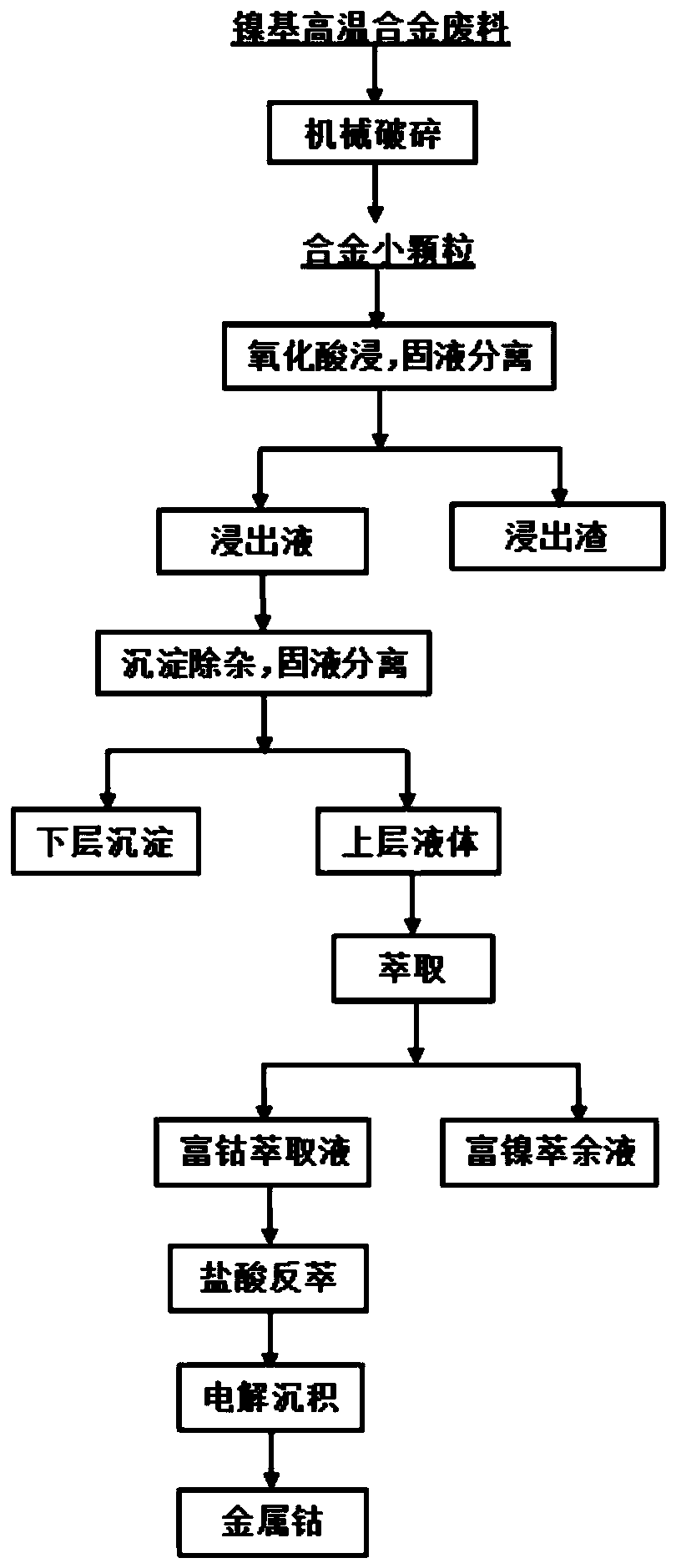

Method for recovering cobalt from nickel-based high-temperature alloy cutting waste material

A nickel-based superalloy and scrap technology, applied in the field of cobalt recovery, can solve the problems of difficult large-scale production, high melting point, high energy consumption, etc., and achieve the effect of saving energy consumption, low investment cost and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The mass fraction of cobalt in the nickel-base superalloy cutting scrap used in this example is 10%.

[0029] (1) breaking nickel-based high-temperature alloy cutting waste into small particles, and the particle size of the alloy particles is 0.1-5mm;

[0030] (2) Place the small alloy particles described in step (1) in the mixed acid of hydrochloric acid and nitric acid for leaching treatment, obtain leachate and leach slag after solid-liquid separation; described hydrochloric acid concentration is 5mol / L, the concentration of nitric acid is 2.5mol / L, the volume of the inorganic acid V=9m, where m is the mass of the alloy powder in g, and the unit of V is mL; the temperature of the leaching treatment is 75°C, and the time of the leaching treatment for 2h;

[0031] (3) Use the alkali solution as a precipitating agent to slowly adjust the pH of the system until the pH value of the reaction system is 5.0, and then perform solid-liquid separation; the temperature of the p...

Embodiment 2

[0036] The mass fraction of cobalt in the nickel-based superalloy cutting scrap used in this example is 12%.

[0037] (1) breaking nickel-based high-temperature alloy cutting waste into small particles, and the particle size of the alloy particles is 0.1-5mm;

[0038] (2) Place the small alloy particles described in step (1) in the mixed acid of hydrochloric acid and nitric acid for leaching treatment, obtain leachate and leach slag after solid-liquid separation; described hydrochloric acid concentration is 6mol / L, the concentration of nitric acid is 2.5mol / L, the volume of the inorganic acid V=8m, where m is the mass of the alloy powder in g, and the unit of V is mL; the temperature of the leaching treatment is 80°C, and the time of the leaching treatment for 2h;

[0039] (3) Use the alkali solution as a precipitating agent to slowly adjust the pH of the system until the pH value of the reaction system is 5.0, and then carry out solid-liquid separation; the temperature of th...

Embodiment 3

[0044] The mass fraction of cobalt in the nickel-based superalloy cutting waste used in this example is 15%.

[0045] (1) breaking nickel-based high-temperature alloy cutting waste into small particles, and the particle size of the alloy particles is 0.1-5mm;

[0046] (2) Place the small alloy particles described in step (1) in the mixed acid of hydrochloric acid and nitric acid for leaching treatment, obtain leachate and leach slag after solid-liquid separation; described hydrochloric acid concentration is 6mol / L, the concentration of nitric acid is 3mol / L, the volume of the inorganic acid V=9m, wherein m is the quality of the alloy powder, the unit is g, and the unit of V is mL; the temperature of the leaching treatment is 80°C, and the time of the leaching treatment is 2h;

[0047](3) Use the alkali solution as a precipitating agent to slowly adjust the pH of the system until the pH value of the reaction system is 5.0, and then carry out solid-liquid separation; the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com