SrTaO2N oxynitride nano powder and preparation method thereof

A technology of oxynitride and nanopowder, which is applied in the direction of nitrogen and non-metallic compounds, nanotechnology, nanotechnology, etc., can solve the problems of high cost, slow gas-solid reaction diffusion, shortening nitriding time, etc., and achieve the effect of inhibiting urea Decomposition, shortening the reaction time, improving the effect of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A kind of SrTaO of the present invention 2 The preparation method of N oxynitride nanopowder comprises the following steps:

[0038] S1. Dissolving alkaline earth metal salt, tantalum salt and nitrogen source I in alcohol, ball milling and drying to obtain a mixed precursor;

[0039] S2. Place the mixed precursor obtained in step S1 and nitrogen source II in a reaction vessel, and calcinate in a protective atmosphere to obtain SrTaO 2 N oxynitride nanopowder; wherein, the mixed precursor and the nitrogen source II are arranged at intervals.

[0040] The present invention SrTaO 2 The preparation method of N oxynitride nanopowder, when calcining, the mixed precursor and the organic nitrogen source II are arranged at intervals, and there are two distribution forms of the nitrogen source: one is the nitrogen source I mixed in the mixed precursor, and the other is Nitrogen source II, when the temperature rises, the nitrogen source II can decompose to produce ammonia gas. ...

Embodiment 1

[0042] A kind of SrTaO of this embodiment 2 The preparation method of N oxynitride nanopowder comprises the following steps:

[0043] S1. Add 3.5g of strontium carbonate, 4.5g of tantalum pentoxide and 2.4g of urea into 20ml of absolute ethanol, and ball mill for 240min to obtain a mixed slurry;

[0044] S2. Drying the mixed slurry obtained after ball milling in step S1. The drying process is as follows: heat preservation at 60° C. for 24 hours to obtain a mixed precursor;

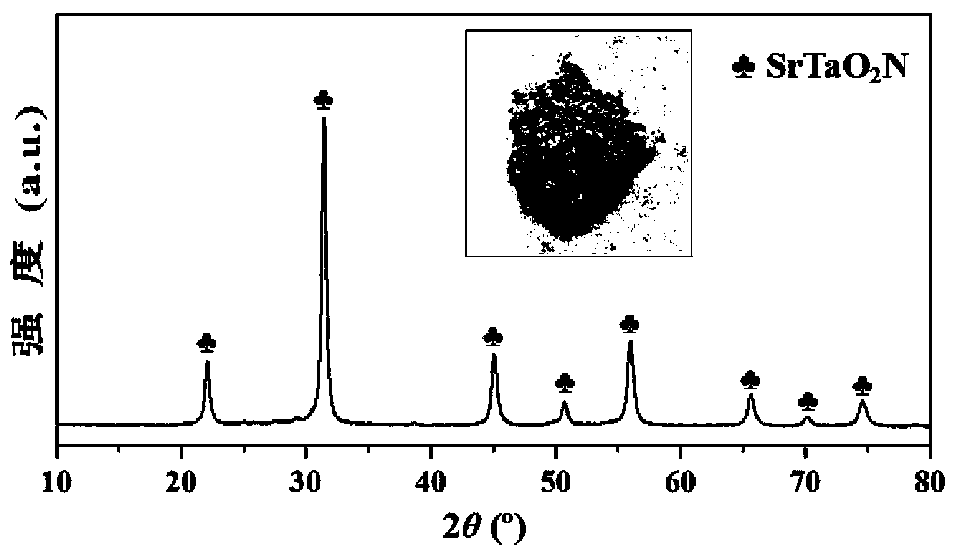

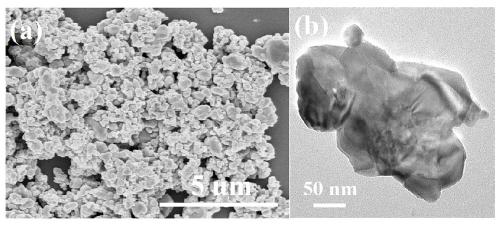

[0045] S3. Place the mixed precursor and urea obtained in step S2 in a reaction container and place them at intervals, including 5 g of urea; then calcinate in a nitrogen atmosphere, the heating rate is 100°C / min, the temperature is 1100°C, and the holding time is 60min; Cool the furnace to room temperature to get SrTaO 2 N oxynitride nano powder, its phase composition and microscopic appearance are as follows figure 2 with image 3 shown.

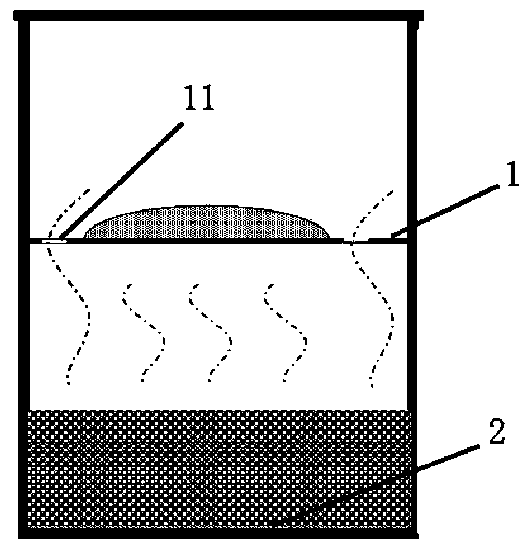

[0046] Such as figure 1 As shown, the reaction container o...

Embodiment 2

[0062] A kind of SrTaO of this embodiment 2 The preparation method of N oxynitride nanopowder comprises the following steps:

[0063] S1. Add 3.5g of strontium carbonate, 4.5g of tantalum pentoxide and 2g of urea into 20ml of absolute ethanol, and ball mill for 240min to obtain a mixed slurry;

[0064] S2. Drying the mixed slurry obtained after ball milling in step S1. The drying process is as follows: heat preservation at 60° C. for 24 hours to obtain a mixed precursor;

[0065] S3. Place the mixed precursor and urea obtained in step S2 in a reaction container and place them at intervals, in which 4 g of urea is placed; then calcined in a nitrogen atmosphere with a heating rate of 100°C / min, a temperature of 1100°C, and a holding time of 30 minutes; finally Cool to room temperature with the furnace to get SrTaO 2 N oxynitride nanopowder.

[0066] The reaction vessel used in this embodiment is the same as in Example 1.

[0067] The SrTaO prepared in this example 2 The pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com