A kind of refining method of vasopressin

A refining method, vasopressin technology, applied in the preparation method of peptide, oxytocin/vasopressin, separation method, etc., can solve the problem of large amount of organic hazardous waste liquid, high cost of waste liquid treatment, uneconomical, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Packing of L&L4002 preparative column with inner diameter of 50mm

[0049] Using Load&Lock dynamic axial compression and static locking technology, packing ODS-AQ, pore size 10nm, particle size 10μm, packed to column bed pressure 1000psi, using Varian chromatography packing system, 300g dry powder filler, 600ml isopropanol after stirring and homogenizing, poured into L&L4002 preparative column with inner diameter 50mm, compression ratio 1.5: 1, the carrier gas is N 2 , adjust the carrier gas pressure so that the oil pressure gauge pressure is 1500psi, and the dynamic axial compression to the height of the column bed is 25cm, which is used as a preparative column for reverse-phase enrichment, reverse-phase salt conversion and reverse-phase purification schemes.

Embodiment 2

[0050] Example 2 Reverse-phase enrichment, reverse-phase salt conversion and reverse-phase purification of crude vasopressin solution

[0051] Instrument: Varian SD-1 high pressure liquid phase preparation system

[0052] Chromatographic column: self-packed preparative column Load&Lock4002 50×250mm, ODS-AQ 10μm 10nm

[0053] The structural formula of vasopressin is The concentration of the crude reduced vasopressin in the crude reduced vasopressin solution is 1.0 mg / ml, and the solvent in the crude vasopressin solution is an aqueous solution containing trifluoroacetic acid and acetic acid.

[0054] The mobile phase A is 0.02% acetic acid / water by volume, and the mobile phase B is 0.02% acetic acid / acetonitrile by volume. Sample C1 is a crude product solution of vasopressin. The HPLC purity determined by the HPLC method is 73.63%, and the mobile phase C2 is 10 mM NH 4 Ac-NH 4 OH pH7.5 aqueous solution.

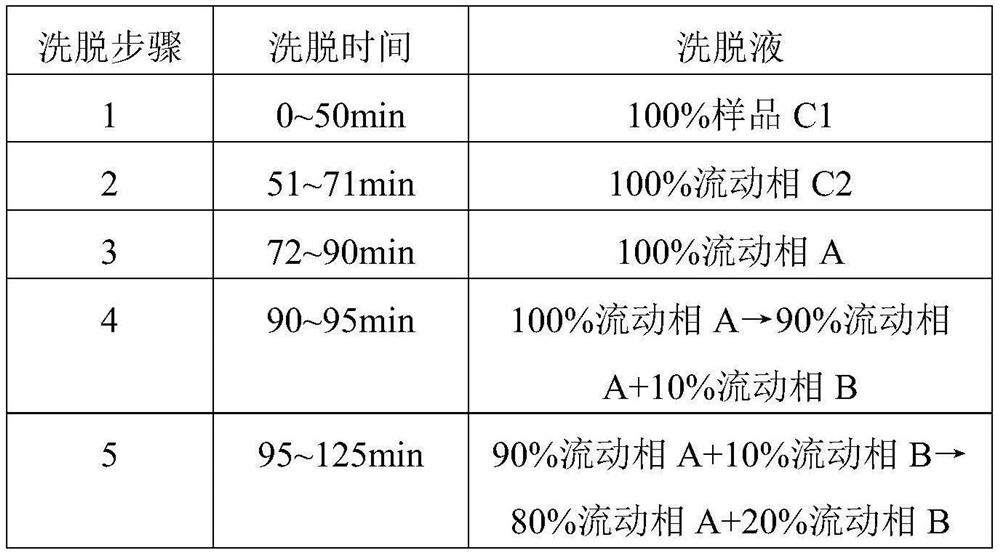

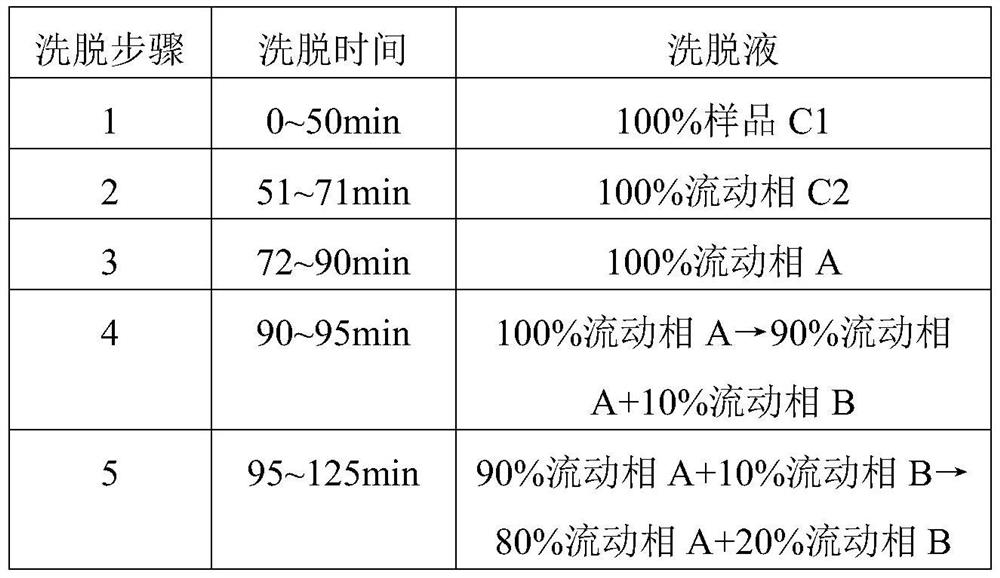

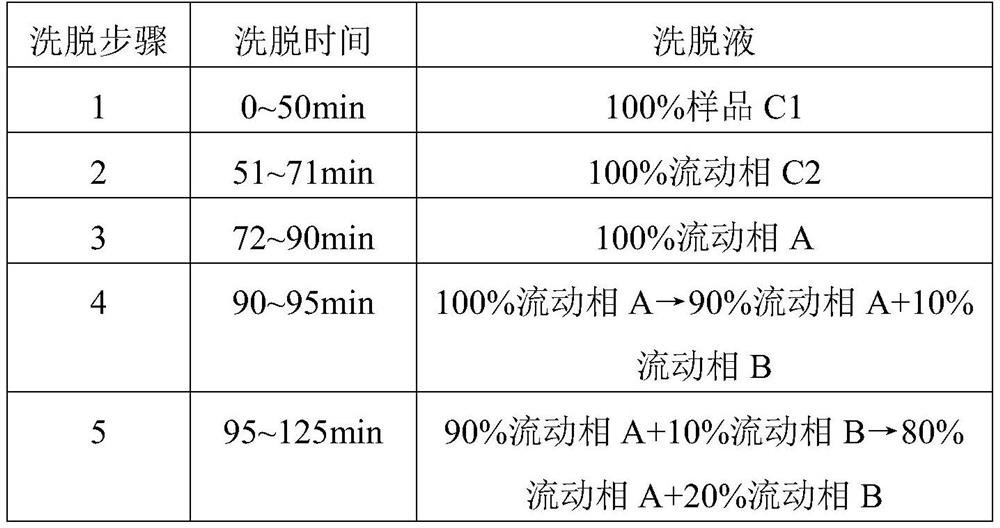

[0055] The reverse-phase enrichment, reverse-phase salt transfer a...

Embodiment 3

[0059] Example 3 Reverse-phase enrichment, reverse-phase salt conversion and reverse-phase purification of crude vasopressin solution

[0060] Instrument: Varian SD-1 high pressure liquid phase preparation system

[0061] Chromatographic column: self-packed preparative column Load&Lock4002 50×250mm, ODS-AQ 10μm 10nm

[0062] The structural formula of vasopressin is The concentration of the crude reduced vasopressin in the crude reduced vasopressin solution is 1.5 mg / ml, and the solvent in the crude vasopressin solution is an aqueous solution containing trifluoroacetic acid and acetic acid.

[0063] Mobile phase A is 0.05% acetic acid / water by volume, and mobile phase B is 0.05% acetic acid / acetonitrile by volume. Sample C1 is a crude vasopressin solution. The HPLC purity determined by the HPLC method is 75.23%, and the mobile phase C2 is 20mM NH 4 Ac-NH 4 OH pH8.5 aqueous solution.

[0064] The reverse-phase enrichment, reverse-phase salt transfer and reverse-phase pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com