A kind of red phosphorus flame-retardant nylon composite material and its preparation method and the determination method of phosphorus precipitation amount in it

A technology of flame retardant nylon and composite materials, applied in material excitation analysis, thermal excitation analysis, etc., can solve the problems of unfavorable smoke density and odor control, low metal corrosion, inability to stabilize, etc., and achieve high tracking index. , The effect of excellent anti-precipitation performance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

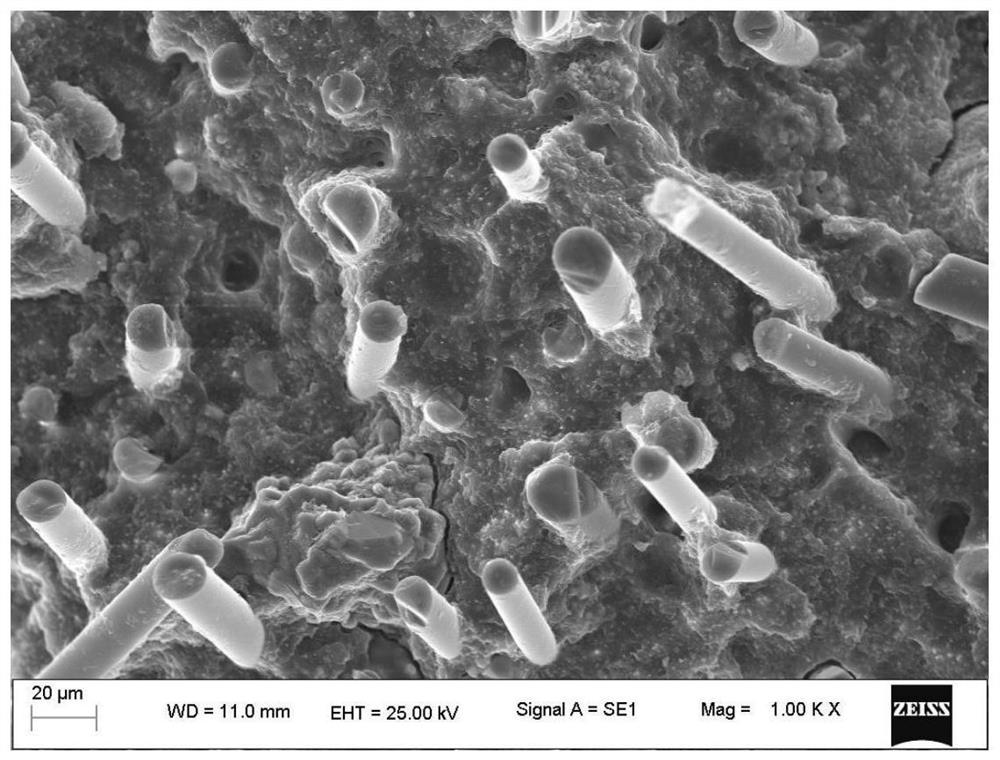

Image

Examples

Embodiment 1

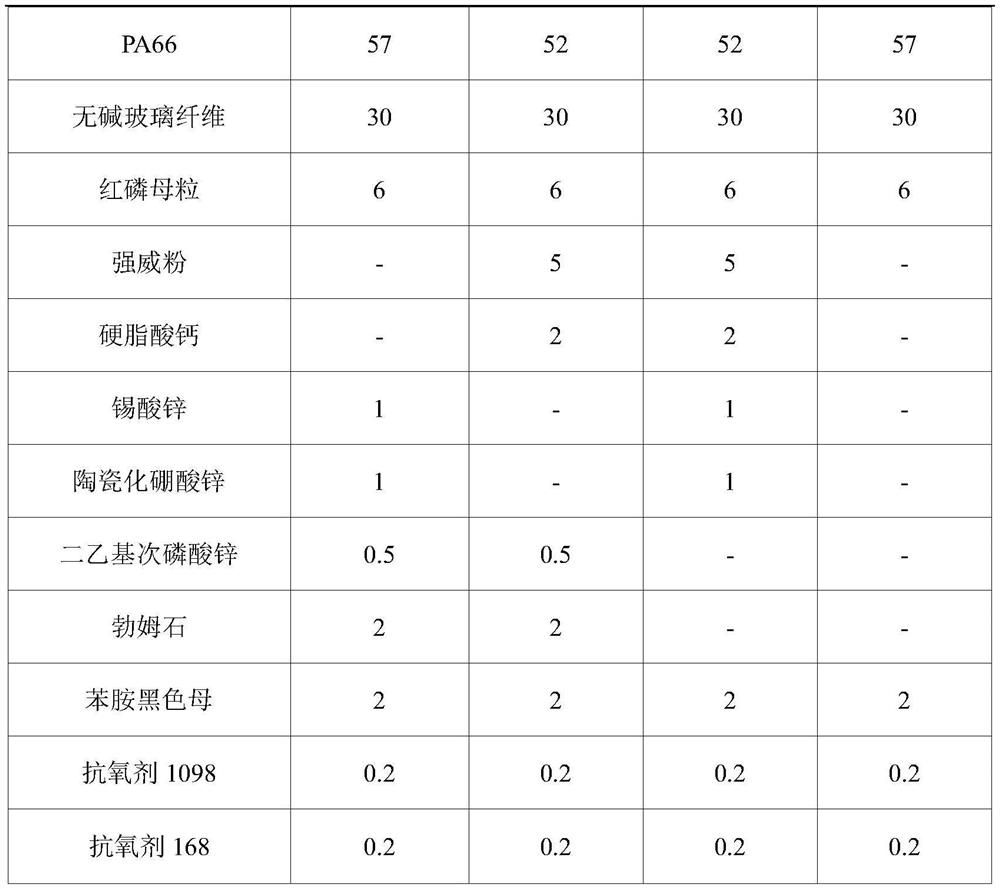

[0047] A red phosphorus flame-retardant nylon composite material, its components and the weight parts of each component are shown in Table 1 below.

[0048] The preparation method of the above-mentioned red phosphorus flame-retardant nylon composite material comprises the following steps:

[0049] (1) Dry the nylon resin and red phosphorus masterbatch in hot air at 120°C for 4 hours, and set aside;

[0050] (2) Mix nylon resin, red phosphorus flame retardant, red phosphorus stabilizer, smoke suppressant, CTI enhancer, black masterbatch and antioxidant in a homogenizing pot at high speed, and keep the speed at 100-500 rpm Minutes, mixing time is 3 minutes, obtains homogeneous mixture;

[0051] (3) Add the mixture obtained in step (2) into the hopper of the twin-screw extruder, then add the reinforcement component from the side feeding port of the twin-screw extruder, melt blending, extrusion, cooling , air-drying, and pelletizing to prepare the red phosphorus flame-retardant ...

Embodiment 2-8

[0055] The components and preparation methods of the red phosphorus flame-retardant nylon composite materials in Examples 2-8 are the same as those in Example 1, but the parts by weight of each component are different from those in Example 1. See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com