A method of catalytic oxygen decomposition of lignin to prepare extract containing vanillin and syringaldehyde

A technology for lignin and vanillin, which is applied in the field of catalytic oxygenolysis of lignin to prepare extracts containing vanillin and syringaldehyde, can solve the problems of harsh reaction conditions of strong acid and strong alkali, low yield of target products, corrosive environment of equipment and the like, Achieve the effect of low price, stable hydrothermal performance and easy oxidative depolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Step 1, the preprocessing method is:

[0047] 1.1 Add corn stalk lignin with 5% NaHCO at a solid-to-liquid ratio of 1:10 3 In the aqueous solution, stir at room temperature for 6 hours to obtain a sample of corn stalk lignin;

[0048] 1.2 Suction filter the sample in 1.1 above, and rinse the filter residue with deionized water for 3 times;

[0049] 1.3 Dry the sample obtained in the above 1.2 in an oven, the drying temperature is 80°C, and the drying time is 12 hours;

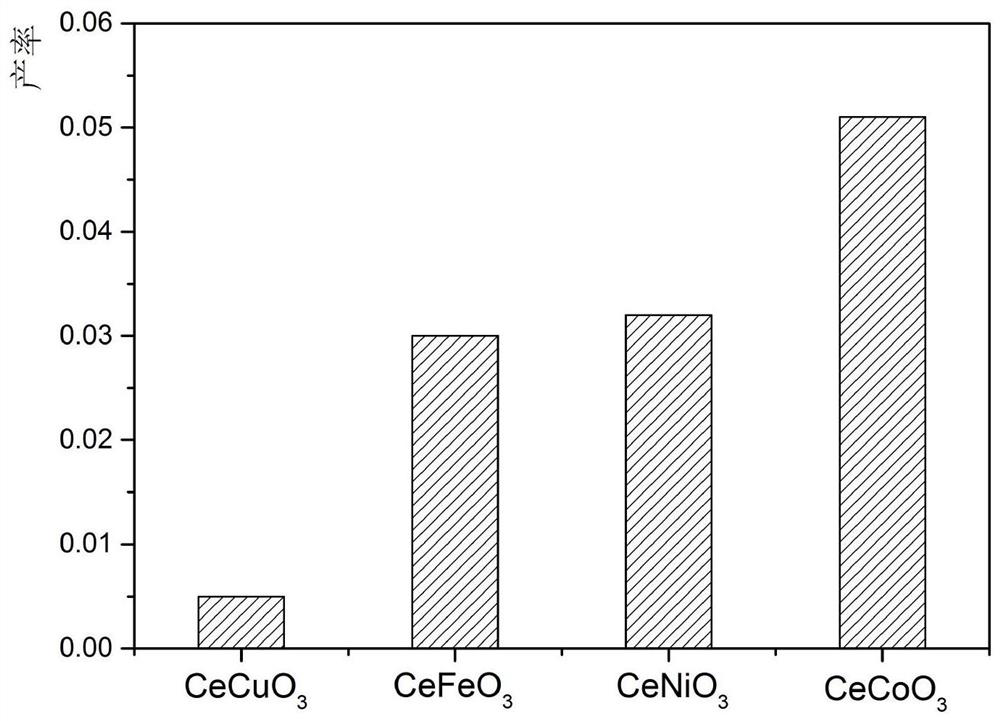

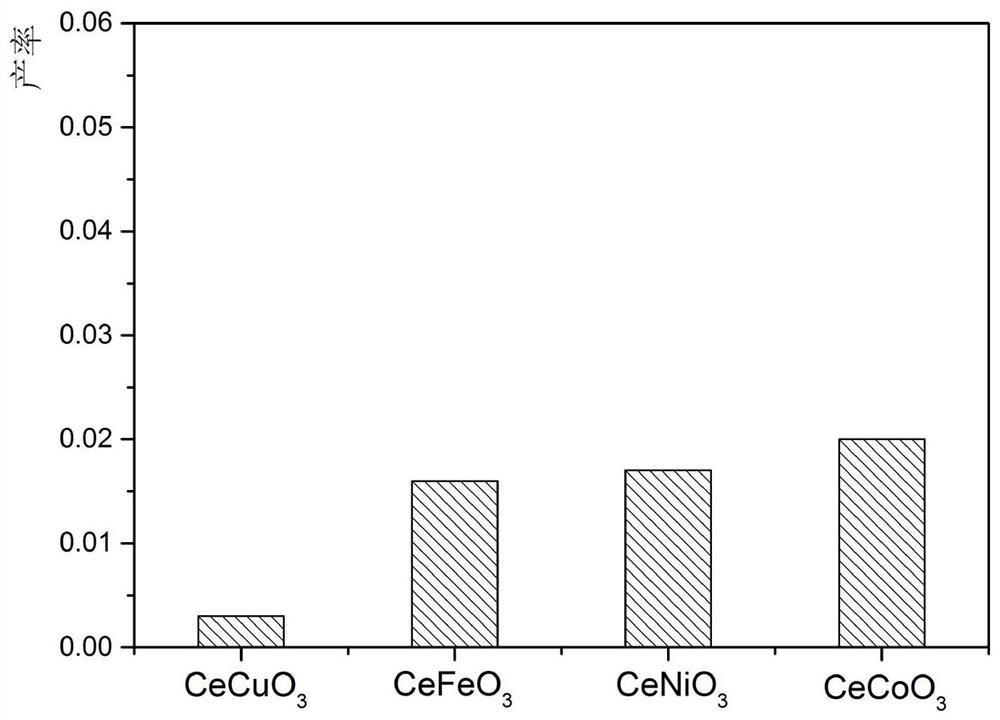

[0050] Step 2, pretreated 0.2g of corn stover lignin and 0.02g of perovskite catalyst CeCoO 3 , CeCuO 3 , CeFeO 3 , CeNiO 3 One of them is placed in a reaction kettle, and 20ml of ethanol / water mixed solvent is added, and the volume ratio of ethanol and water in the mixed solvent is 1:1; the reaction kettle is filled with nitrogen to 1MPa, and then exhausted, and repeated three times Complete the purging process; then feed oxygen into the reactor to 0.6MPa; set the reaction temperature to 180°C and...

example 2

[0053] Step 1, the preprocessing method is:

[0054] 1.1 Add corn stalk lignin with 5% NaHCO at a solid-to-liquid ratio of 1:10 3 In the aqueous solution, stir at room temperature for 6 hours to obtain a sample of corn stalk lignin;

[0055] 1.2 Suction filter the sample in 1.1 above, and rinse the filter residue with deionized water for 3 times;

[0056] 1.3 Dry the sample obtained in the above 1.2 in an oven, the drying temperature is 80°C, and the drying time is 12 hours;

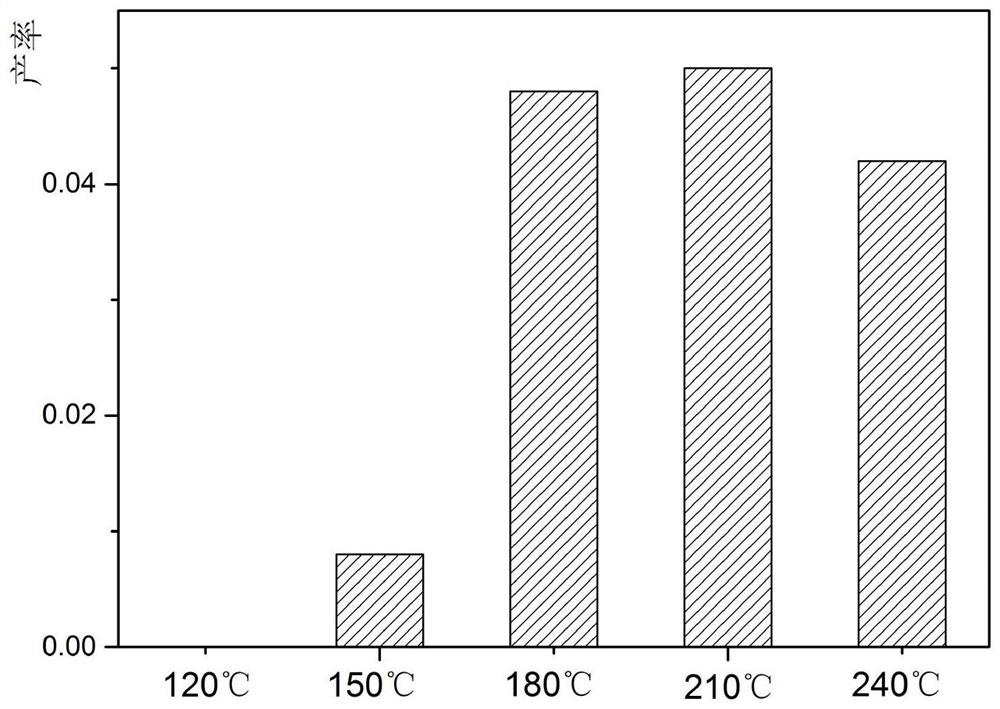

[0057] Step 2, pretreated 0.2g of corn stover lignin and 0.02g of perovskite catalyst CeCoO 3 Placed in the reaction kettle, the volume ratio of ethanol and water in the mixed solvent is 1:1; fill the reaction kettle with nitrogen to 1MPa, then exhaust, repeat three times to complete the purging process; then pass into the reaction kettle Oxygen to 0.6MPa; set the reaction temperature to 120°C, and the reaction time to 60 minutes; after the reaction, place the reaction kettle in a mixture of ice and w...

example 3

[0060] Step 1, the preprocessing method is:

[0061] 1.1 Add corn stalk lignin with 5% NaHCO at a solid-to-liquid ratio of 1:10 3 In the aqueous solution, stir at room temperature for 6 hours to obtain a sample of corn stalk lignin;

[0062] 1.2 Suction filter the sample in 1.1 above, and rinse the filter residue with deionized water for 3 times;

[0063] 1.3 Dry the sample obtained in the above 1.2 in an oven, the drying temperature is 80°C, and the drying time is 12 hours;

[0064] Step 2, pretreated 0.2g of corn stover lignin and 0.02g of perovskite catalyst CeCoO 3 Put it in the reaction kettle, add 20ml of ethanol / water mixed solvent, the volume ratio of ethanol and water in the mixed solvent is 1:1; fill the reaction kettle with nitrogen to 1MPa, then exhaust, repeat three times to complete the purging process ; Next, feed oxygen into the reactor to 0.6MPa; set the reaction temperature to 150°C, and the reaction time to 60 minutes. After the reaction, place the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com