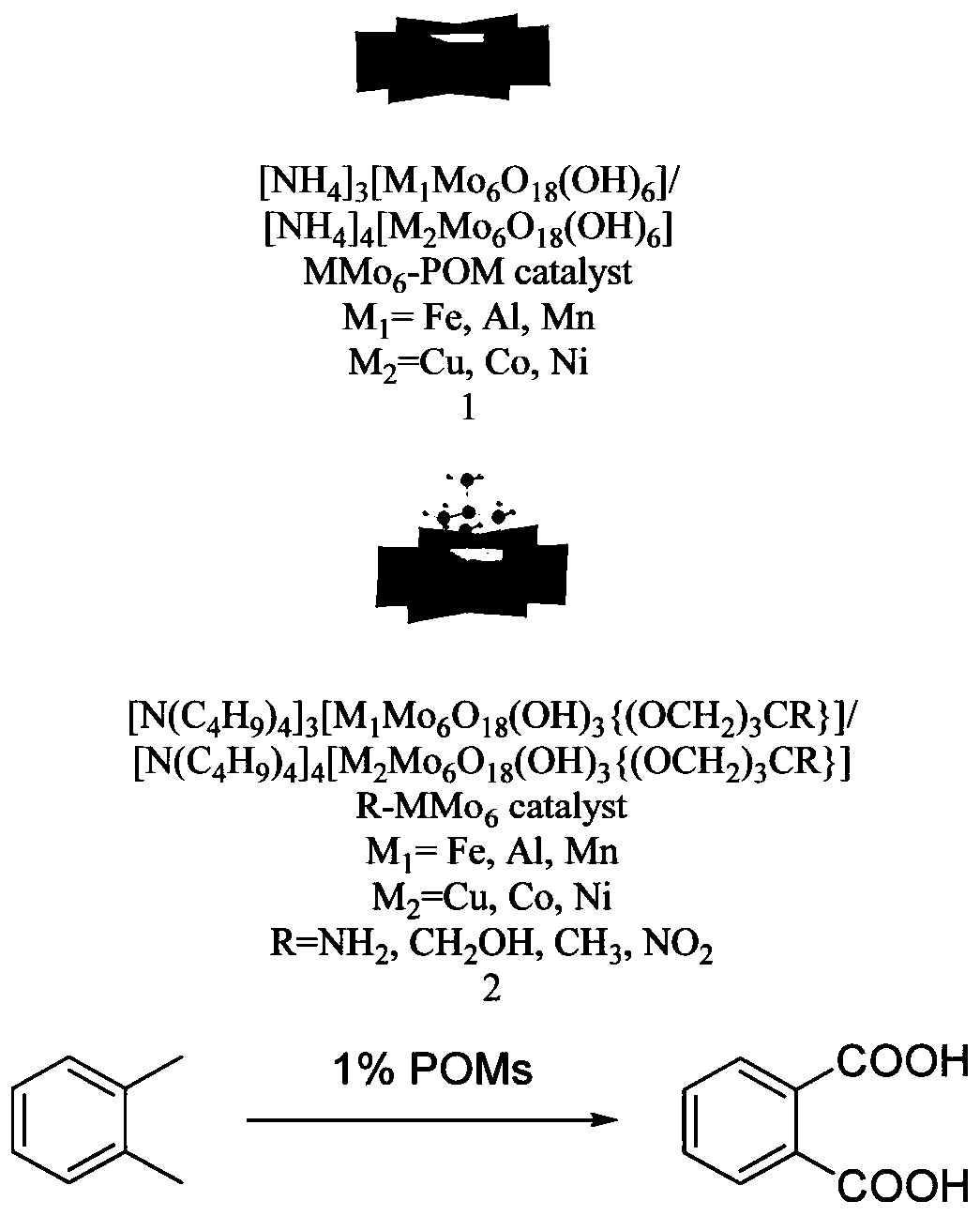

Method of preparing phthalic acid by polyacid catalyzed oxidation

A technology of phthalic acid and o-xylene, applied in the field of catalytic chemistry and daily chemical industry, can solve the problems of precursor reagents, limited application, high toxicity, etc., reduce manufacturing costs and the generation of three wastes, and avoid halogens The use of initiators, ease of control and effects of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0048] Add 1.0617g (0.01mol) of o-xylene, 1% (0.0076g) of Fe-Anderson type polyoxometalate, 1% (0.00106g) of sodium carbonate additive, and 5equiv (0.3g) of solvent acetic acid Put it into a dry reaction test tube, raise the temperature to 100° C., place the reaction in air, keep the reaction at a pressure (gauge pressure) of 1.0 MPa for 20 hours, and then stop the reaction. The reaction system was extracted 3 times with ethyl acetate, the solvent was removed from the obtained product under reduced pressure, and phthalic acid was separated by column chromatography to obtain 0.8956 g of the product with a yield of 54%.

Embodiment example 2

[0050] 1.0617g (0.01mol) of o-xylene, 1% (0.076g) of Fe-Anderson type polyoxometalate, 1% (0.00106g) of sodium carbonate additive, and 5equiv (3g) of solvent acetic acid into In the hydrothermal reaction kettle lined with polytetrafluoroethylene, pay attention to check whether the equipment is damaged before use, add solvent and raw materials into the hydrothermal reaction kettle container, stir and dissolve, and blow nitrogen into the container for a period of time to make The system is in an inert atmosphere. Tighten the lid of the medium hydrothermal reaction kettle, then add the catalyst and place it in the oven. After the temperature rises to 100°C, connect the oxygen tank so that the pressure (gauge pressure) is about 1.0MPa, and keep it warm for 12 hours. Stop responding. After the kettle body was naturally cooled to room temperature, the lid of the kettle was opened, and the reaction system was extracted 3 times with ethyl acetate, and the obtained product was decompre...

Embodiment example 3

[0052] The o-xylene of 1.0617g (0.01mol), the Fe-Anderson type polyoxometalate catalyst of 1% (0.0076g), the sodium carbonate additive of 1% (0.00106g), the hydrogen peroxide of 30% of 3equiv and Put 5 equiv (0.3g) of solvent acetic acid into a dry and clean pressure-resistant tube, raise the temperature to 100°C, and keep the pressure (gauge pressure) at 1.0MPa for 12 hours, then stop the reaction, and dilute the reaction system with ethyl acetate. Extracted 3 times, the obtained product was desolventized under reduced pressure, separated by column chromatography to obtain phthalic acid, 1.2937 g of the product was obtained, and the yield was 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com