Method for preparing ribavirin through genetically engineered bacteria

A technology of genetically engineered bacteria and gene fragments, applied in the field of preparing ribavirin by using genetically engineered bacteria, can solve the problems of low substrate concentration, large amount of bacteria, long reaction time, etc., to reduce energy consumption and shorten reaction time , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

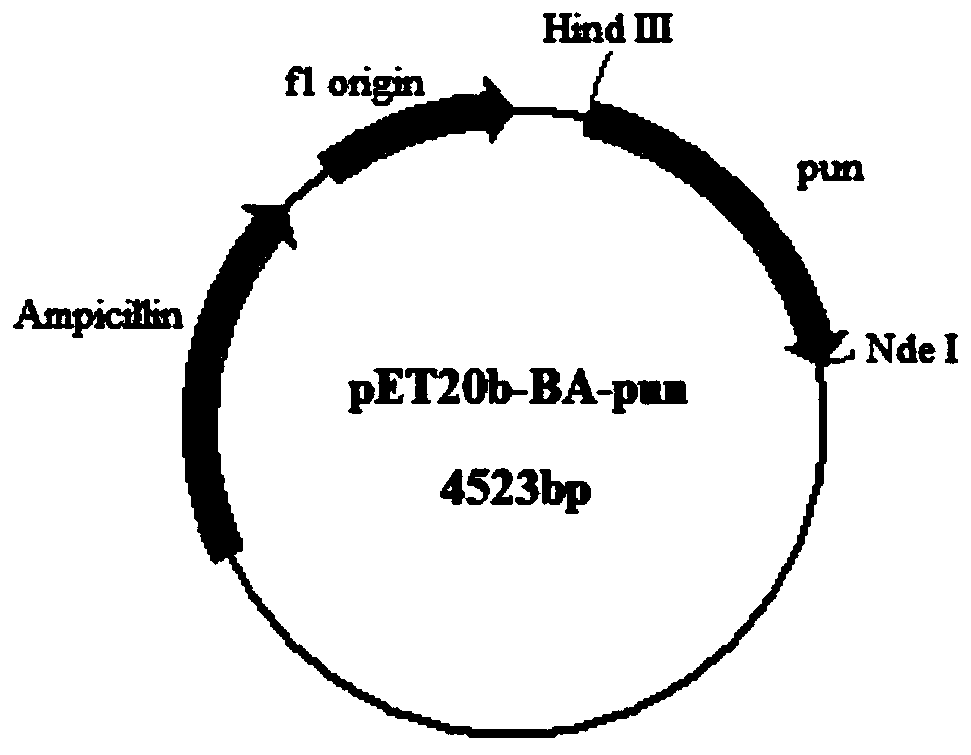

[0055] Synthesis and vector construction of the target fragment of embodiment 1

[0056] 1. Synthesis of target fragments

[0057] It is known that there is a 21-amino acid sequence at the N-terminal of Brevibacterium acetylene, and the gene sequence pun gene of purine nucleoside phosphorylase was obtained from the whole genome of Brevibacterium acetylides by sequence comparison, with a total of 810bp (SEQ ID NO: 1). According to the sequence information, two restriction sites were added to both ends of the sequence, namely NdeI and Hind III. Send the designed sequence information to Nanjing GenScript Biotechnology Co., Ltd. for synthesis.

[0058] 2. Construction of recombinant plasmid pET20b-BA-pun

[0059] The fully synthetic purine nucleoside phosphorylase encoding gene pun was connected with the expression vector pET20b to construct a constitutive expression vector pET20b-BA-pun with high expression efficiency and high plasmid stability. The constructed recombinant pla...

Embodiment 2

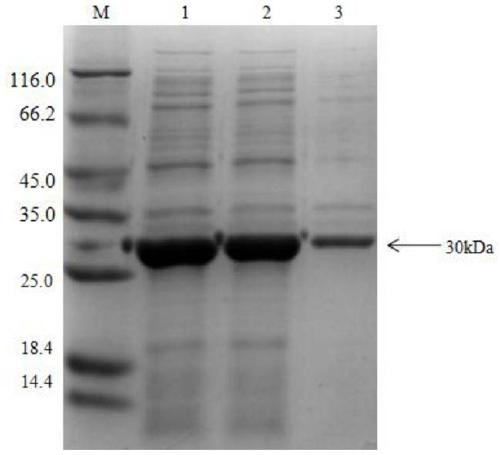

[0062] Induced expression and SDS-PAGE of embodiment 2 target protein

[0063] The recombinant plasmid was transformed into Escherichia coli BL21(DE3) to obtain genetically engineered bacteria BL21 / pET20b-BA-pun.

[0064] Induced expression: Inoculate a single colony of the genetically engineered bacteria BL21 / pET20b-BA-pun into LB liquid medium containing Amp, shake and culture at 220r / min, 37°C for 12h to 16h; Amp's LB liquid medium, shake culture at 220r / min, 37°C until OD 600 =0.6~0.8, add IPTG with a final concentration of 0.1mmol / L as an inducer, and induce expression at 18°C for 18h.

[0065] Centrifuge the cultured bacteria solution to collect the bacteria (10000r / min, 4°C, 10min), wash the bacteria twice with phosphate buffer (PB, 50mmol / L, pH7.0), and then wash the bacteria After the body was resuspended with phosphate buffer (50mmol / L, pH7.0), it was used as the enzyme source for the enzymatic synthesis of ribavirin. Another part of the cell suspension was subj...

Embodiment 3

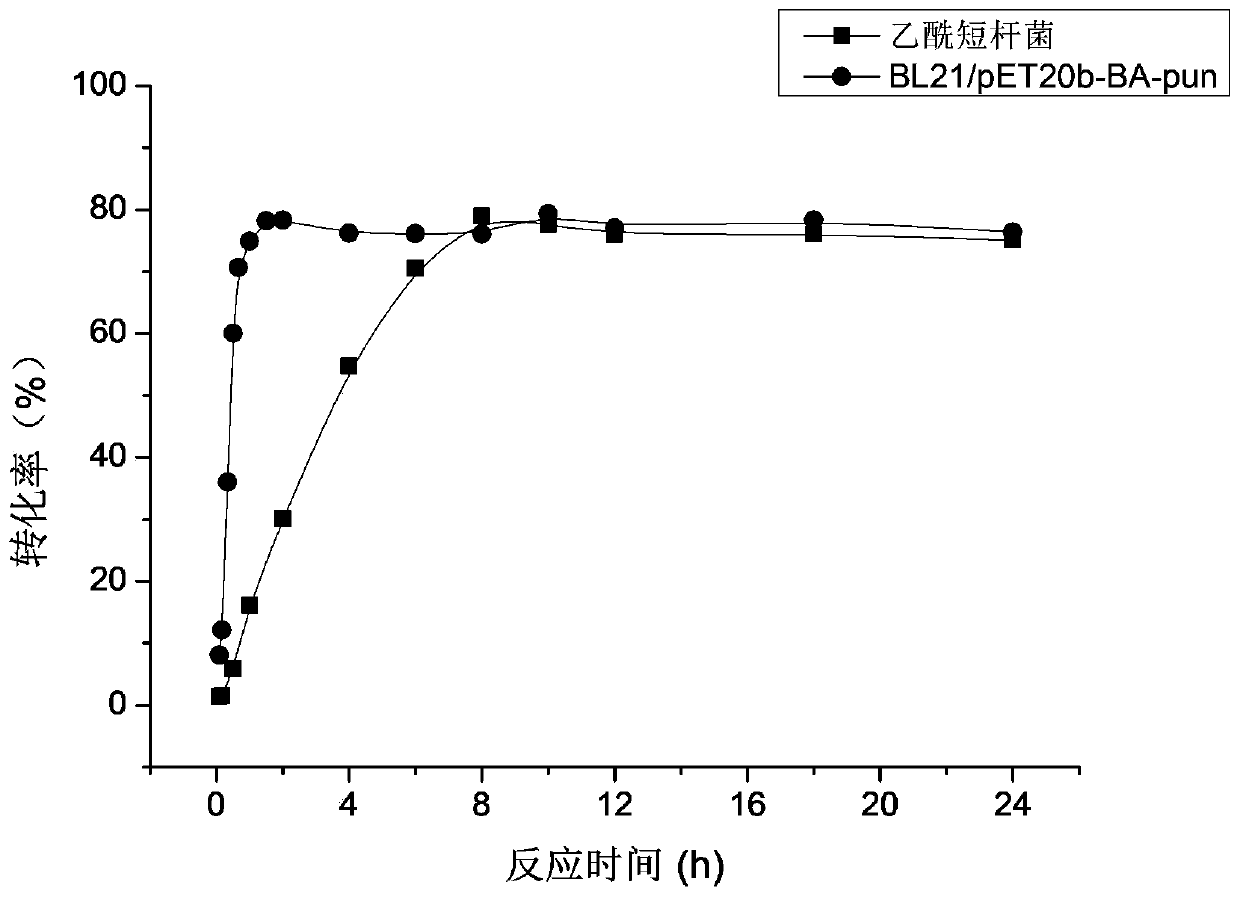

[0067] Embodiment 3 enzymatic reaction prepares ribavirin

[0068] With 50mmol / L, the potassium phosphate buffer solution that pH is 7.0 is reaction solvent, with guanosine (GR) and 1,2,4-triazole-3-carboxamide (TCA) as reaction substrate, guanosine and TCA The molar ratio of the substrate is 1:1, the concentration of the substrate in the reaction solution is 100-400mmol / L, the above-mentioned cells and bacteria are added to the reaction substrate as the enzyme source and mixed evenly, the amount of the enzyme source in the reaction solution is based on wet It is added in a proportion of 0.5% to 5% by weight. Mix the above system and put it into a high-temperature shaker for enzyme conversion, 300r / min, 65°C, and the reaction time is 2h-24h. After the reaction was completed, it was cooled in an ice-water bath. After centrifugation (12000r / min, 4°C, 5min), the supernatant was taken to determine the content of ribavirin.

[0069] After diluting the obtained product solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com