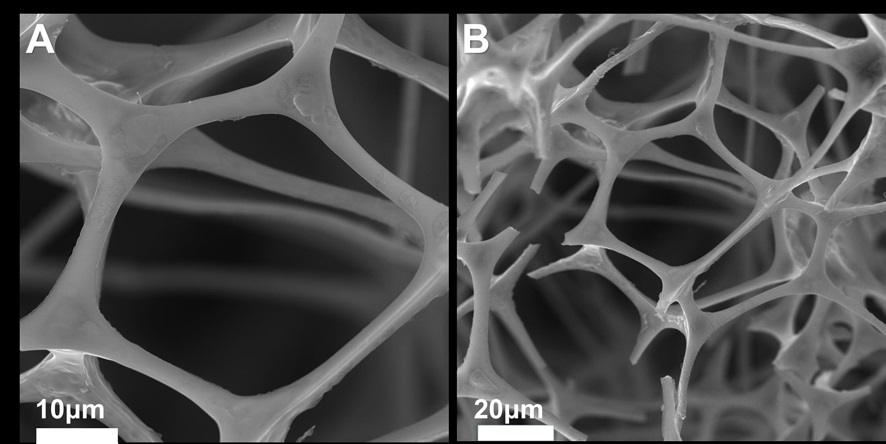

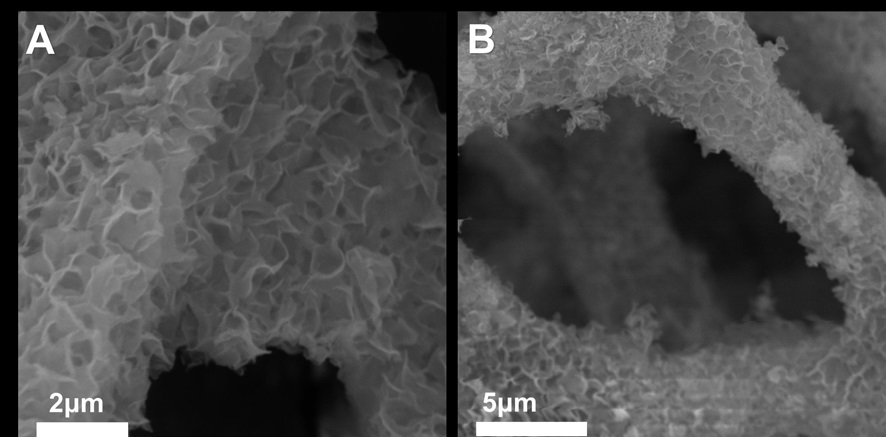

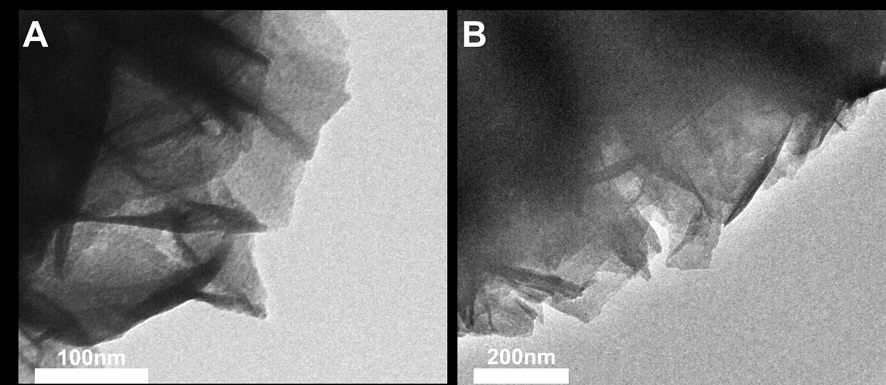

A preparation method based on carbonized melamine foam@Bi2O3 nanosheet supercapacitor electrode material

A carbonized melamine and supercapacitor technology, which is applied in hybrid capacitor electrodes, carbon preparation/purification, chemical instruments and methods, etc., can solve the problems of low redox reversibility, poor cycle stability, low capacitance, etc., and shorten the diffusion path , good electrical conductivity, high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The melamine foam sample (13.0×2.5×2.5 cm 3 ) on a quartz boat and placed in a tube furnace. Before pyrolysis, the sample was passed through argon gas at room temperature for 10-30 min, and the flow rate of argon gas was 1000 standard cubic centimeters per minute, and the air inside was exhausted. The melamine foam was pyrolyzed at 600-800 °C for 1-2 h, and the heating rate was 5-10 °C / min to reach the highest temperature. After pyrolysis, the sample temperature slowly returned to room temperature. The entire heating and cooling process is carried out under continuous argon at 500-1000 sccm / min.

[0029] (2) Weigh 0.97 g of bismuth nitrate pentahydrate and dissolve it in the mixture of ethanol and ethylene glycol, stir and dissolve to obtain a dispersion.

[0030] (3) Cut a small piece of the carbonized melamine foam obtained in step (1) into a polytetrafluoroethylene hydrothermal reaction kettle, and pour the uniform dispersion obtained in step (2) into it for hy...

Embodiment 2

[0034] (1) The melamine foam sample (13.0×2.5×2.5 cm 3) on a quartz boat and placed in a tube furnace. Before pyrolysis, the sample was passed through argon gas at room temperature for 10-30 min, and the flow rate of argon gas was 1000 standard cubic centimeters per minute, and the air inside was exhausted. The melamine foam was pyrolyzed at 600-800 °C for 1-2 h, and the heating rate was 5-10 °C / min to reach the highest temperature. After pyrolysis, the sample temperature rose slowly to 25-40 °C. The entire heating and cooling process is carried out under continuous argon at 500-1000 sccm / min.

[0035] (2) Weigh 1.455 g bismuth nitrate pentahydrate and dissolve it in the mixture of ethanol and ethylene glycol, stir and dissolve to obtain a dispersion.

[0036] (3) Cut a small piece of the carbonized melamine foam obtained in step (1) into a polytetrafluoroethylene hydrothermal reaction kettle, and pour the uniform dispersion obtained in step (2) into it for hydrothermal reac...

Embodiment 3

[0040] (1) The melamine foam sample (13.0×2.5×2.5 cm 3 ) on a quartz boat and placed in a tube furnace. Before pyrolysis, the sample was passed through argon gas at room temperature for 10-30 min, and the flow rate of argon gas was 1000 standard cubic centimeters per minute, and the air inside was exhausted. The melamine foam was pyrolyzed at 600-800 °C for 1-2 h, and the heating rate was 5-10 °C / min to reach the highest temperature. After pyrolysis, the sample temperature rose slowly to 25-40 °C. The entire heating and cooling process is carried out under continuous argon at 500-1000 sccm / min.

[0041] (2) Weigh 1.94 g of bismuth nitrate pentahydrate and dissolve it in the mixture of ethanol and ethylene glycol, stir and dissolve to obtain a dispersion.

[0042] (3) Cut a small piece of the carbonized melamine foam obtained in step (1) into a polytetrafluoroethylene hydrothermal reaction kettle, and pour the uniform dispersion obtained in step (2) into it for hydrothermal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com