Method for preparing ion barrier film of low-light image intensifier

An anti-ion feedback film, low-light image intensifier technology, applied in chemical instruments and methods, discharge tube/lamp manufacturing, cold cathode manufacturing, etc., can solve problems such as increasing production costs, reducing yield, and microchannel pollution. , to achieve the effect of improving production efficiency, improving yield, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail

[0034] In order to make the above and other objects, features and advantages of the present invention more obvious, the following specifically cites the embodiments of the present invention and describes them in detail as follows.

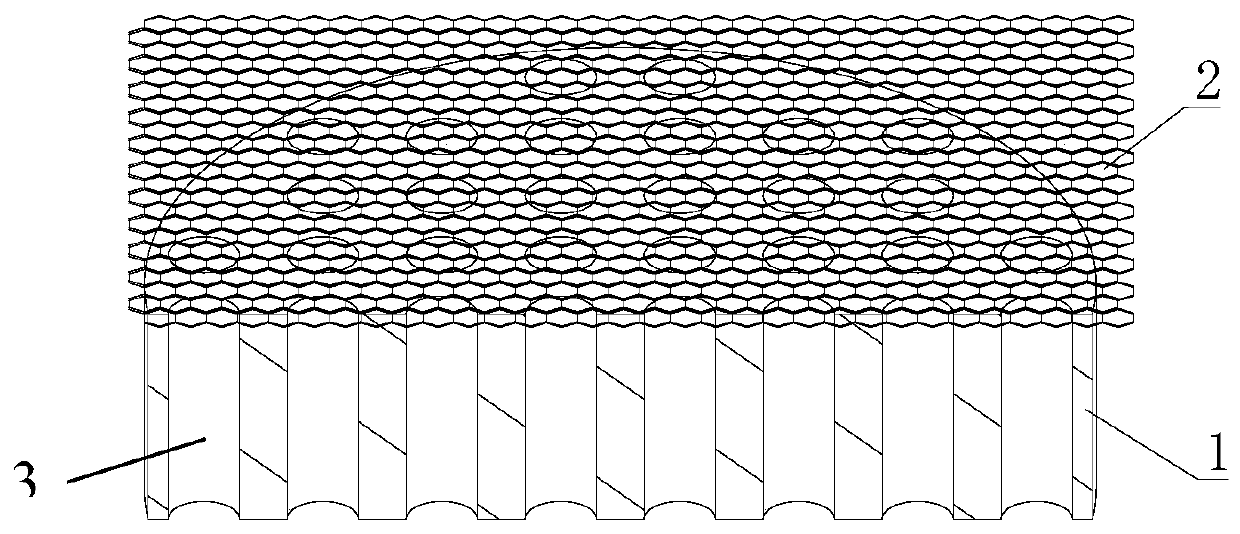

[0035] Graphene is a crystalline material with the highest strength and hardness among known materials, and its fracture strength (strength limit) is 42N / m 2 , the tensile strength and elastic modulus are 130Gpa and 1.0TPa respectively, with excellent mechanical properties and sufficient strength, any point on the film made of graphene can bear its own total weight without causing collapse. At the same time, graphene also has high Young's modulus, thermal conductivity and electrical conductivity, which can effectively block cations.

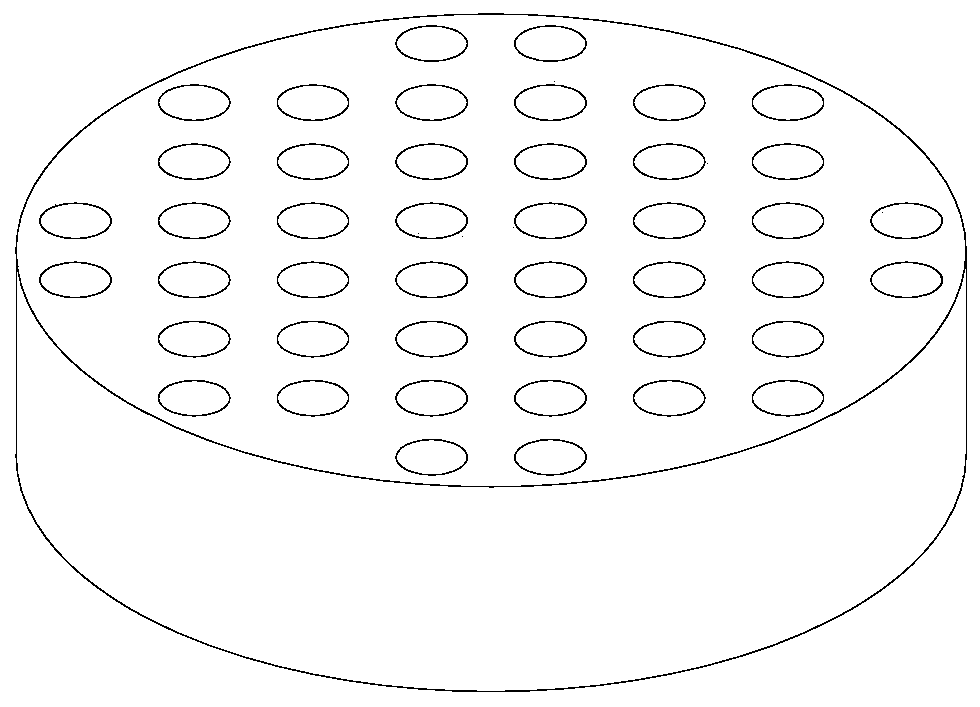

[0036] According to the characteristics of the graphene material, the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com