Current collector suitable for lithium ion battery electrode material and preparation thereof, and application of current collector suitable for lithium ion battery electrode material

A lithium-ion battery, electrode material technology, applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of lithium-ion battery performance degradation, aluminum foil current collector corrosion, etc., to achieve superior performance, easy operation, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A second aspect of the present invention provides a method for preparing a current collector suitable for lithium-ion battery electrode materials, comprising the following steps:

[0042] (1) prepare graphite oxide;

[0043] (2) calcining the product obtained in step (1), cooling to obtain expanded graphite;

[0044] (3) the product that step (2) obtains is processed into flexible graphite paper.

[0045] The preparation methods of flexible graphite (expanded graphite), that is, expanded graphite EG, mainly include chemical oxidation method, electrochemical method, gas phase diffusion method, liquid phase method, melting method, pressurization method, explosion method, etc.

[0046] Since graphite is a non-polar material, it is difficult to intercalate by using organic or inorganic acids with low polarity alone, and generally oxidizing agents must be used. The chemical oxidation method generally involves immersing natural flake graphite in a solution of an oxidizing a...

Embodiment 1

[0088] The preparation of embodiment 1 flexible graphite paper

[0089] Dissolve 0.5g of sodium nitrate in 70ml of 98% concentrated sulfuric acid in a three-necked flask, place it in an ice-water bath and stir for 10 minutes, the temperature in the reaction kettle is 25°C, and then slowly add 1g of sieved graphite passing through a 300-mesh sieve;

[0090] After stirring for 30 minutes, slowly add 3 g of potassium permanganate to the mixture in batches, control the temperature with an ice-water bath, keep the temperature at 25°C, and stir for 2 hours;

[0091]Move the three-necked flask to a constant temperature water bath at 35°C to react for 2 hours. During this period, stir continuously to obtain a brownish-yellow solution. Slowly add 200ml of deionized water dropwise. 1h; the mixture was diluted with 30°C water until the solution temperature was close to 30°C;

[0092] Add 5wt% hydrogen peroxide until a golden yellow solution is obtained, centrifuge the centrifuge, wash t...

Embodiment 2

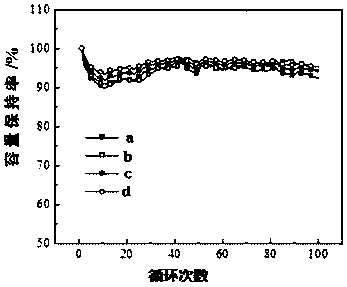

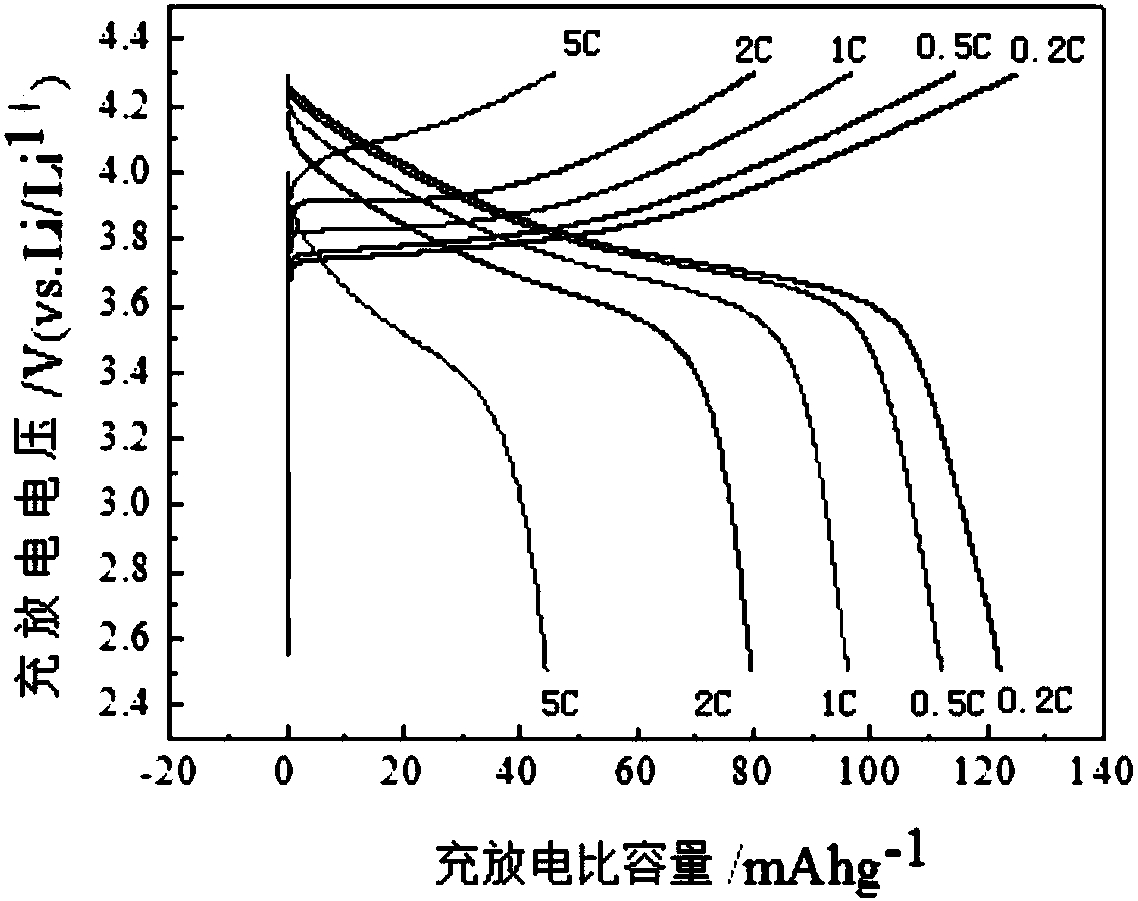

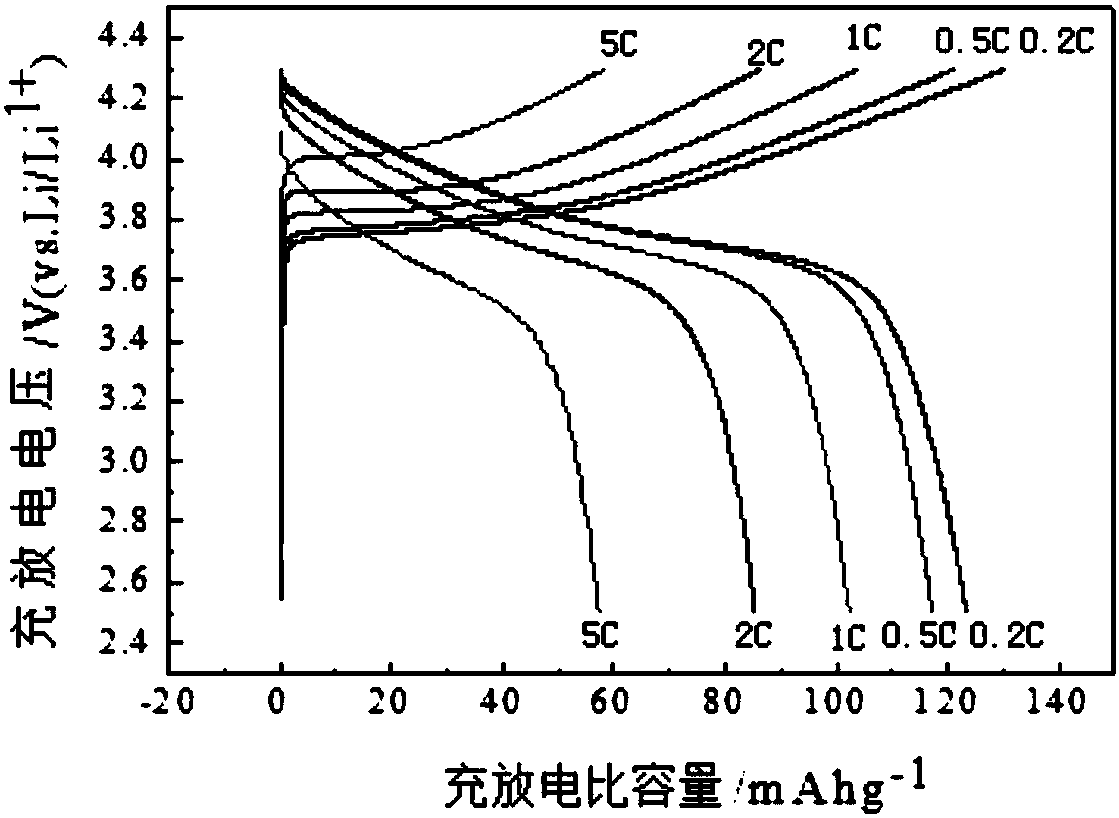

[0097] The preparation of embodiment 2 electrode sheet

[0098] With the ternary material Li(Ni 0.5 co 0.2 mn 0.3 )O 2 As an active material, the flexible graphite paper of the present invention is used as a current collector, and the electrode preparation method formed is as follows:

[0099] The active material, conductive agent, and binder were mixed according to the mass ratio of 8:1:1 to prepare the electrode. The specific preparation process is as follows: first weigh 0.833g of a mass concentration of 7.5% binder PVDF solution (solvent is NMP), put it into a crucible, and add 2 to 3 drops of NMP solvent, and stir rapidly under a magnetic stirrer About 30 minutes to eliminate the bubbles in the binder; then weigh 0.0625g of conductive agent acetylene black, slowly add it into the crucible under stirring, when the slurry gradually becomes viscous, add a few drops of NMP solvent Adjust the thin consistency. After adding acetylene black, continue to stir at high speed f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com