A method for simultaneous resource utilization of iron, sodium and aluminum from red mud

A technology of resource utilization and red mud, applied in the direction of improving process efficiency, can solve the problems of high equipment quality requirements, consumption of iron concentrate, and high cost, achieve good economic benefits, improve iron recovery rate, and improve concentrate grade. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

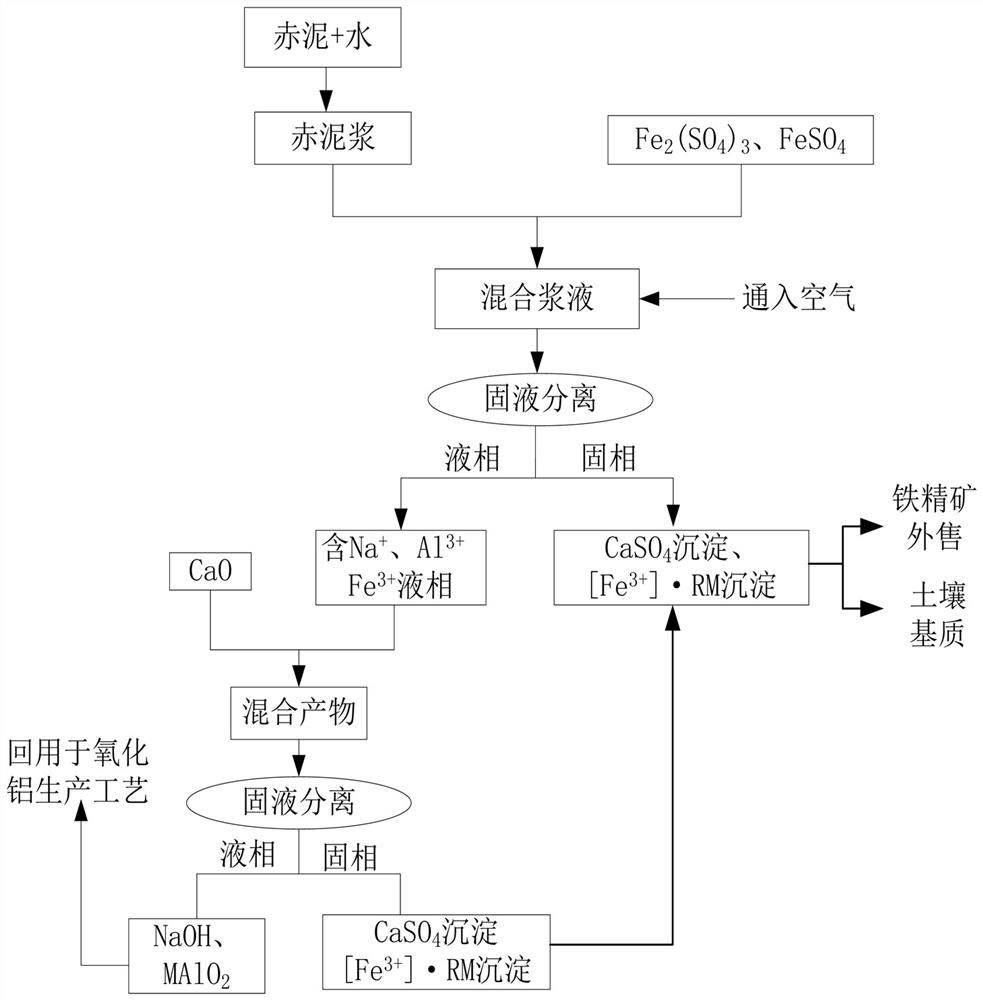

Image

Examples

Embodiment 1

[0035] Filter, dry and grind the red mud, pass through a 300-mesh sieve after grinding to obtain red mud powder, and mix the red mud powder and water uniformly in the red mud presoaking tank according to the solid-to-liquid mass ratio of 1:30 to obtain red mud slurry; FeSO 4 Mix with the red mud slurry according to the solid-liquid mass ratio of 1:20, and introduce air for aeration, the air flow rate is 60mL / min, and the aeration time is 240min, and make it fully react; Part of the bottom slag was sold or treated as a soil matrix. The liquid part reacted with CaO, and the CaO and liquid were mixed according to the solid-liquid mass ratio of 1:10. The reaction temperature was 250 ° C, and the reaction time was 60 minutes. The product is subjected to solid-liquid separation, and the obtained solid-phase bottom slag is treated together with the bottom slag generated during the replacement process, and the liquid-phase part is recycled and reused, mainly for the alumina production ...

Embodiment 2

[0038] Filter, dry and grind the red mud, pass through a 200-mesh sieve after grinding to obtain red mud powder, and mix the red mud powder and water uniformly in the red mud presoaking tank according to the solid-to-liquid mass ratio of 1:30 to obtain red mud slurry; Fe 2 (SO 4 ) 3 Mix with red mud according to the solid-to-liquid mass ratio of 1:20, and then introduce air for aeration, the air flow rate is 60mL / min, and the aeration time is 150min, so that it can fully react; after the reaction, the pulp is separated from solid to liquid, and the solid-phase bottom slag Some of them are sold out or treated as soil matrix. The liquid phase reacts with CaO. The CaO and liquid phase are mixed according to the solid-liquid mass ratio of 1:10. The reaction temperature is 250°C and the reaction time is 60 minutes. Solid-liquid separation, the obtained solid phase bottom slag is treated together with the bottom slag generated during the replacement process, and the liquid phase pa...

Embodiment 3

[0041] Filter, dry and grind the red mud, pass through a 250-mesh sieve after grinding to obtain red mud powder, and mix the red mud powder and water uniformly in the red mud presoaking tank according to the solid-to-liquid mass ratio of 1:30 to obtain red mud slurry; FeSO 4 and Fe 2 (SO 4 ) 3 Mix with the red mud slurry according to the solid-liquid mass ratio of 1:20, and aerate with air at a flow rate of 60mL / min, and the aeration time is 180min, so that it can fully react; Part of the bottom slag was sold or treated as a soil matrix. The liquid phase was reacted with CaO. The CaO and liquid phase were mixed at a solid-to-liquid mass ratio of 1:10. The reaction temperature was 250°C and the reaction time was 60 minutes. The product is subjected to solid-liquid separation, and the obtained solid-phase bottom slag is treated together with the bottom slag generated during the replacement process, and the liquid-phase part is recycled and reused, mainly for the alumina produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com