Nanodiamond array and preparation method thereof

A nano-diamond and array technology, applied in the field of diamond, can solve the problems of nano-diamond array conical direction and density, many factors affecting the nano-diamond array, non-uniform nano-diamond array size, and complicated operation steps, so as to achieve easy control of growth conditions and improve operability Sexual, highly consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

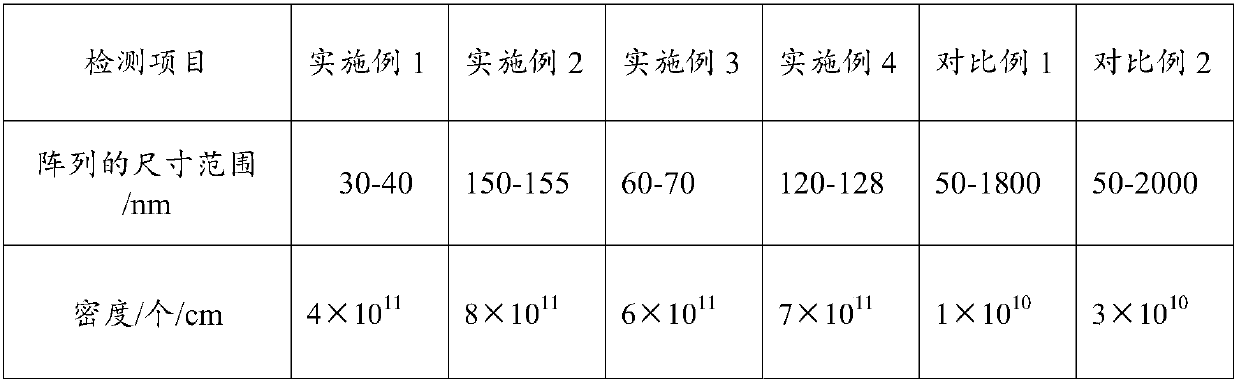

[0047] The preparation method of the nano-diamond array provided by the invention adopts the anodized aluminum template as a substrate, and grows the nano-diamond array on it by a deposition method. Compared with the traditional graphite conversion method, the preparation method avoids harsh conversion conditions and improves operability. Compared with the traditional silicon-based manufacturing process, this preparation method avoids the etching process of nano-diamonds. Therefore, the preparation method provided by the present invention has simple process steps and easy control of growth conditions, so the obtained High-density, high-purity and regular ordered nano-diamond array with a density of 3×10 11 cm -1 ~9×10 11 cm -1 , the structure size of the array in the nano-diamond array is between 5nm and 150nm, and the size of the array structure is not more than 10nm, maintaining a high degree of consistency.

[0048] In one embodiment of the present invention, the prepar...

Embodiment 1

[0071] This embodiment is a method for preparing a nano-diamond array, comprising the following steps:

[0072] Step a) Pretreatment: ultrasonically clean a high-purity aluminum sheet with a purity of 99.99% and a thickness of 0.15 mm in acetone for 5 minutes to remove surface oil, and then place it in a horse-boiler furnace for annealing at a temperature of 300-400°C , the annealing time is 2-3 hours; after that, the annealed and cooled aluminum sheet is electrolytically polished, the aluminum sheet is used as the anode, the platinum is used as the cathode, and the polishing solution is a mixture of perchloric acid and ethanol with a volume ratio of 1:4. For: voltage 15-20V, temperature 0-6 ℃, polishing time 3-5min;

[0073] Step b) the first anodic oxidation: the pretreated aluminum sheet is used as the anode, the platinum sheet is used as the cathode, and the oxalic acid solution of 0.4mol / L is used as the electrolyte for the first anodic oxidation, and the oxidation is per...

Embodiment 2

[0082] This embodiment is a preparation method of a nano-diamond array. Compared with the preparation method provided in Example 1, the voltage in the first anodic oxidation process in this embodiment is 50V, and the voltage in the second anodic oxidation process is 50V. Also be 50V, all the other technological parameters are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com