Liquid medium based temperature-controlled and voltage-controlled lithium battery formation device

A liquid medium and formation device technology, which is applied in the field of lithium battery formation equipment, can solve the problems of long cooling time, wear, and uneven force of fixtures and lithium batteries, and achieve improved lithium battery performance, high safety factor, and uniform pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

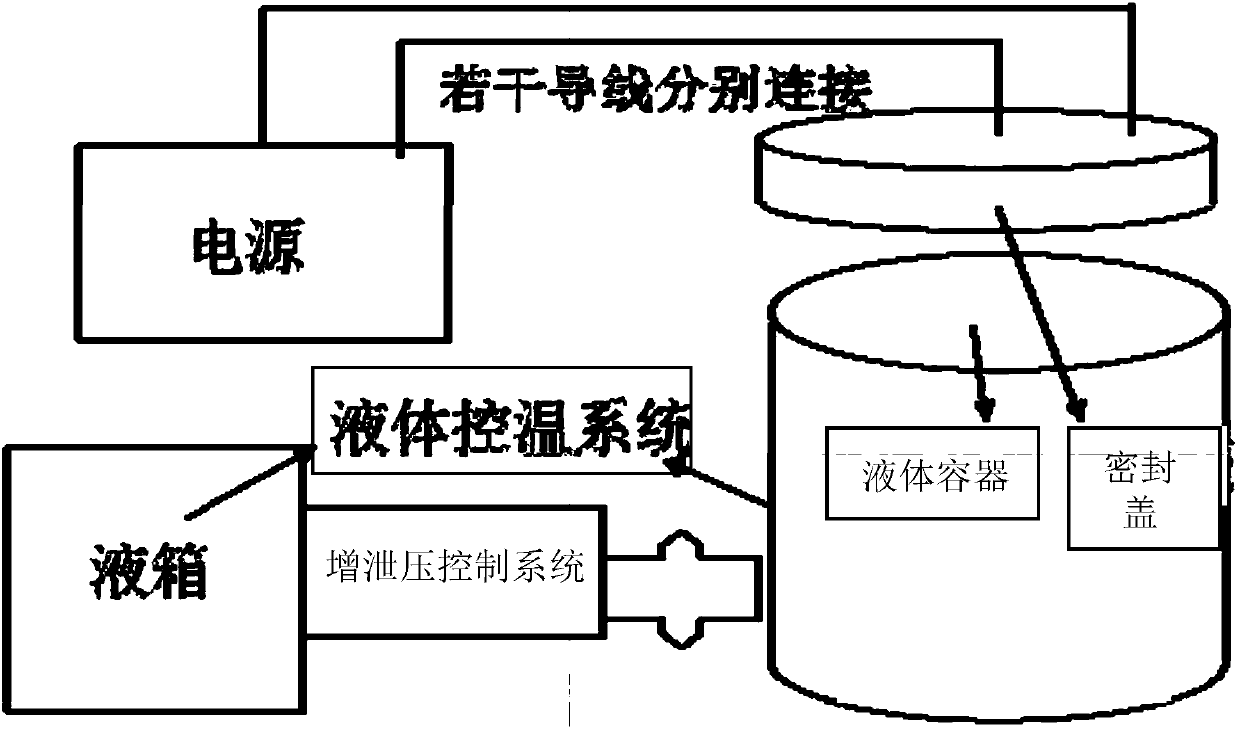

[0046] Such as figure 1 As shown, the liquid medium temperature and pressure controlled lithium battery formation device of the present invention includes a power supply, a sealing cover, a liquid tank, a liquid temperature control system, a pressure increase and release control system, and a sealable tank.

[0047] The sealing cover, liquid tank, pressure boosting and releasing control system and sealable tank are all made of pressure-resistant stainless steel. A material rack made of polytetrafluoroethylene is arranged in the sealable tank body.

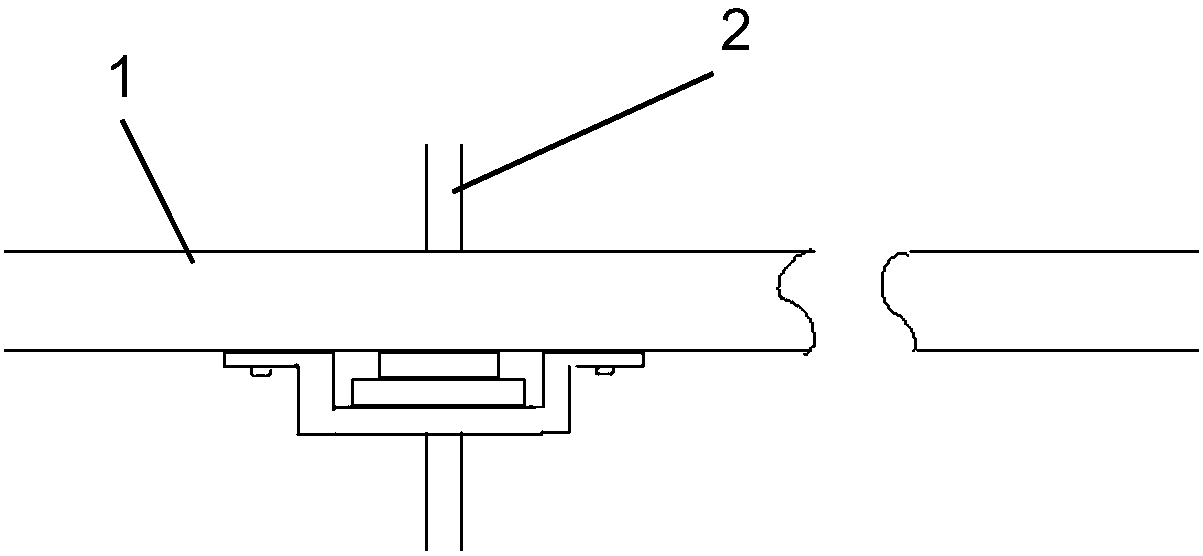

[0048] The power supply is connected with the sealing cover, and four poles are arranged on the sealing cover, and the poles are insulated. The connection between the pole and the sealing cover body is sealed and sealed in a structural way, see figure 2 .

[0049] The power supply has the functions of measuring the voltage, current, temperature, capacitance and internal resistance of the lithium battery between the poles.

[0...

Embodiment 2

[0055] The only difference from Example 1 is: 1. The sealing cover, the liquid tank, the pressure increase and release control system and the sealing tank are all made of iron alloy, and 20 poles are arranged on the sealing cover, and the poles are made of vacuum ceramic electrodes. The electrodes and the sealing cover After the cover is riveted, it is sealed by welding. 2. Set automatic gate valve for pressure relief control. 3. There is a fast electric heating column in the liquid tank, and a cooling pipe is set on the inner wall of the tank. The temperature range of the liquid can be controlled from -40 to 300 degrees. 4. The sealing cover can be pressurized and sealed with the sealed tank body through the sealing control system, and the entire system can withstand a maximum pressure of 250MPa. The sealing of the cover adopts screw sealing, which is driven by electric screw rod.

[0056] This embodiment is applicable to temperature-controlled and pressure-controlled forma...

Embodiment 3

[0058] The only difference from Example 1 is: 1. The sealing cover, the liquid tank, the pressure increase and release control system and the sealing tank body are all made of iron alloy, the power supply is connected to the sealing cover, and 20 poles are arranged on the sealing cover, and the poles adopt vacuum Ceramic electrode, electrode and cover are riveted and sealed by welding. 2. The power supply has the functions of measuring the voltage, current, temperature, capacitance, internal resistance and other functions of the lithium battery between the poles, and can recycle the discharged energy of the lithium battery and feed it back to the grid. 3. Set up a booster pump to control the pressurization of the tank, and set up an automatic gate valve for pressure relief control. There is a liquid sampling port on the pressure relief branch, which is connected to a color difference meter and a density meter for sampling and comparison at any time. 4. There is a fast electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Under pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com