Bimetallic modified magnetic biomass activated carbon adsorbent, its preparation method and application in waste water treatment

An activated carbon adsorption and biomass technology, applied in the direction of adsorption of water/sewage treatment, alkali metal compounds, water/sewage treatment, etc., can solve the problems of cumbersome process steps, high preparation costs, and environmental pollution of reactants, and achieve a wide range of raw material sources , The preparation process is simple, the effect of high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

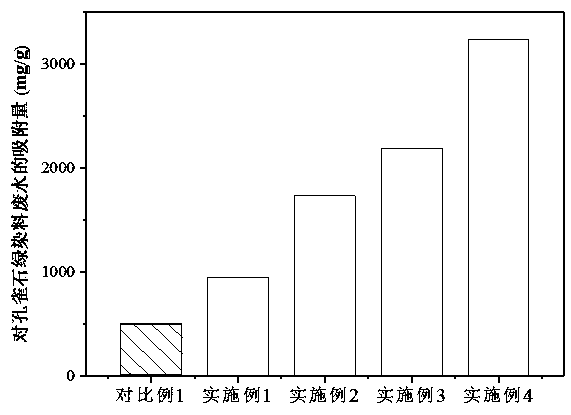

[0029] A bimetallic modified magnetic biomass activated carbon adsorbent, comprising components by mass: 20 g of peanut shell powder, FeCl 3 ·6H 2 O 10 g, MgCl 2 ·6H 2 O 2.5 g.

[0030] The preparation method is as follows:

[0031] Step 1, washing peanut shells with deionized water, drying at 105°C for 48 hours, crushing to 60-100 mesh and drying for later use;

[0032] Step 2, weigh 10 g FeCl respectively 3 ·6H 2 O and 2.5 g MgCl 2 ·6H 2 O was dissolved in 150ml of deionized water, 20 g of peanut shell powder was added, and after magnetic stirring at room temperature for 12 h, the solid was collected by suction filtration and dried in an oven at 105 °C for 24 h to obtain the precursor of Fe-Mg bimetallic biomass activated carbon ;

[0033] Step 3, first pass CO with a flow rate of 250 mL / min 2 After degassing for 30 min, about 6 g of precursor solid powder was weighed and placed in a horizontal tube furnace, and the activation temperature was set at 800 °C. 2 Acti...

Embodiment 2

[0036] A bimetallic modified magnetic biomass activated carbon adsorbent, peanut shell powder 20 g, FeCl 3 ·6H 2 O 10 g, MgCl 2 ·6H 2 O 5 g.

[0037] The preparation method is as follows:

[0038] Step 1, washing peanut shells with deionized water, drying at 105°C for 48 hours, crushing to 60-100 mesh and drying for later use;

[0039] Step 2, weigh 10 g FeCl respectively 3 ·6H 2 O and 5 g MgCl 2 ·6H 2 O was dissolved in 150ml of deionized water, 20g of peanut shell powder was added, and after magnetic stirring at room temperature for 12 hours, the solid was collected by suction filtration and dried in an oven at 105°C for 24 hours to obtain the precursor of Fe-Mg bimetallic biomass activated carbon;

[0040] Step 3, first pass CO with a flow rate of 250 mL / min 2 After degassing for 30 min, about 6 g of precursor solid powder was weighed and placed in a horizontal tube furnace, and the activation temperature was set at 800 °C. 2 Activation in the atmosphere for 90 mi...

Embodiment 3

[0043] A bimetallic modified magnetic biomass activated carbon adsorbent, peanut shell powder 20 g, FeCl 3 ·6H 2 O 10 g, MgCl 2 ·6H 2 O 10 g.

[0044] The preparation method is as follows:

[0045] Step 1, washing peanut shells with deionized water, drying at 105°C for 48 hours, crushing to 60-100 mesh and drying for later use;

[0046] Step 2, weigh 10 g FeCl respectively 3 ·6H 2 O and 10 g MgCl 2 ·6H 2 O was dissolved in 150ml of deionized water, 20g of peanut shell powder was added, and after magnetic stirring at room temperature for 12 hours, the solid was collected by suction filtration and dried in an oven at 105°C for 24 hours to obtain the precursor of Fe-Mg bimetallic biomass activated carbon;

[0047] Step 3, first pass CO with a flow rate of 250 mL / min 2 After degassing for 30 min, about 6 g of precursor solid powder was weighed and placed in a horizontal tube furnace, and the activation temperature was set at 800 °C. 2 Activation in the atmosphere for 90 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com