Preparation method and application of lithium ion battery ternary positive electrode material

A technology for lithium ion batteries and positive electrode materials, which is applied to battery electrodes, positive electrodes, electrical components, etc., can solve the problems of unsatisfactory product uniformity, increased production cost, narrow distribution range, etc., and achieves low production cost and small particle size. , the effect of uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

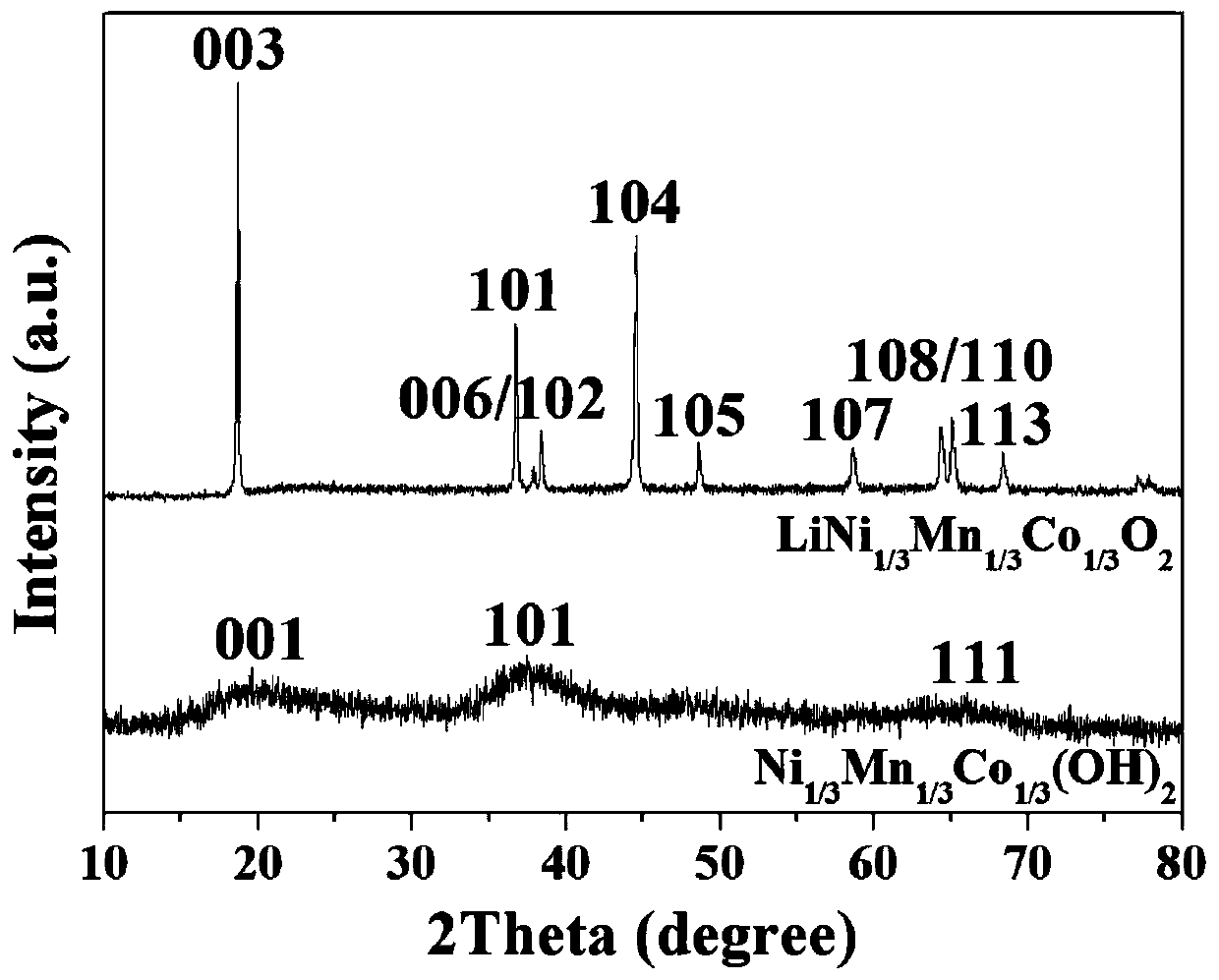

[0037] (1) Preparation of Ni by direct current electrochemical method 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 Precursors and LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Ternary cathode material

[0038] The nickel-manganese-cobalt alloy (111) / nickel-manganese-cobalt alloy as the working electrode was immersed in 300mL 2mol / L potassium nitrate electrolyte solution. The DC voltage was then set to 10V for electrolysis. After the electrolysis, the electrolyzed product was centrifuged, washed five times with distilled water and ethanol, and dried at 60°C for collection. Grind and mix the dried electrolysis product and lithium carbonate uniformly at a molar ratio of 1.2, place it in a tube furnace, and calcinate it in air at 800°C for 12h with a heating rate of 10°C / min, and collect it after cooling for later use.

[0039] (2) LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Application of Cathode Materials in Li-ion Batteries

[0040] Will LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The powder is mixed with activated carbon and polyv...

Embodiment 2

[0043] (1) Preparation of Ni by direct current electrochemical method 0.6 co 0.2 mn 0.2 (OH) 2 Precursors and LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary cathode material

[0044] The nickel-manganese-cobalt alloy (622) / platinum as the working electrode was immersed in 300mL of 0.5mol / L sodium sulfate electrolyte solution. The DC voltage was then set to 8V for electrolysis. After the electrolysis, the electrolyzed product was centrifuged, washed five times with distilled water and ethanol, and dried at 80°C for collection. Grind and mix the dried electrolysis product and lithium hydroxide uniformly at a molar ratio of 0.8, place it in a tube furnace, and calcinate it in air at 850°C for 16 hours with a heating rate of 5°C / min, and collect it after cooling for later use.

[0045] (2) LiNi 0.6 co 0.2 mn 0.2 o 2 Application of Cathode Materials in Li-ion Batteries

[0046] Will LiNi 0.6 co 0.2 mn 0.2 o 2 The powder is mixed with activated carbon and polyvinylidene fluori...

Embodiment 3

[0049] (1) Preparation of Ni by direct current electrochemical method 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 Precursors and LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Ternary cathode material

[0050] The nickel-manganese-cobalt alloy (111) / nickel as the working electrode was immersed in 500mL of 1mol / L sodium chloride electrolyte solution. The DC voltage was then set to 15V for electrolysis. After the electrolysis, the electrolyzed product was centrifuged, washed five times with distilled water and ethanol, and dried at 80°C for collection. Grind and mix the dried electrolysis product and lithium carbonate uniformly at a molar ratio of 1.05, place it in a tube furnace, and calcinate it in air at 900°C for 18h with a heating rate of 4°C / min, collect it after cooling for later use.

[0051] (2) LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Application of Cathode Materials in Li-ion Batteries

[0052] Will LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The powder is mixed with activated carbon and polyvinylidene fluoride binder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com