A kind of electrolyte solution for lithium battery and preparation method thereof

An electrolyte and lithium battery technology, applied in the field of lithium battery electrolyte and its preparation, can solve the problems of high flammability and poor low temperature performance, and achieve the effects of excellent low temperature performance, large electrochemical window and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

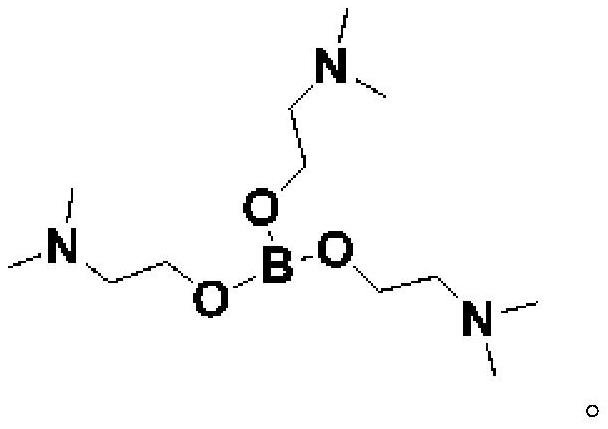

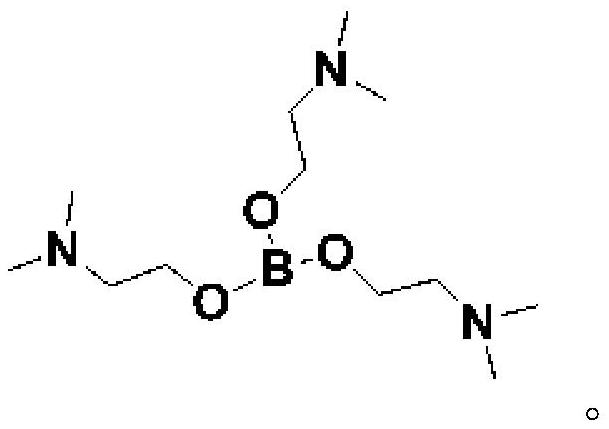

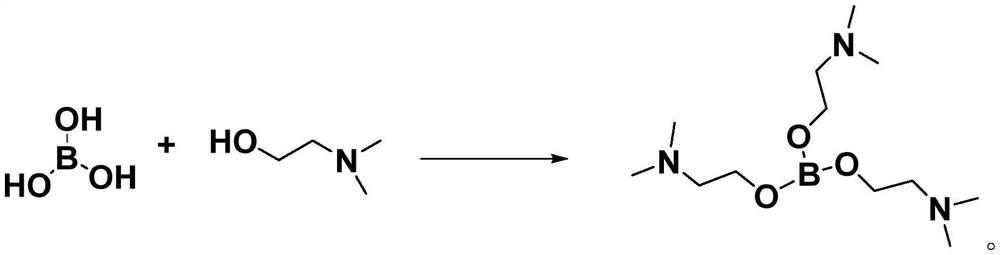

[0021] (1) Under the Dean-Stark device, boric acid and 2-dimethylaminoethanol were dissolved in 150ml toluene at a molar ratio of 1:3.2 and placed in a 250ml round bottom flask, and heated under reflux one day. All volatiles were removed from the resulting liquid in a rotary evaporator and high vacuum distillation. A pure transparent organic liquid based on a borate aminoether ligand symmetrical star organic solvent was obtained after passing through an alumina column. Yield 97%.

[0022] (2) 1 g of lithium bistrifluoromethanesulfonimide (LiTFSI) was dissolved in 2.5 g of the above product (boron compound) solvent to prepare a liquid electrolyte solution.

[0023] A polypropylene separator is immersed in an electrolyte solution, and the soaked separator can be used as a liquid electrolyte.

[0024] The freezing point of the pure boron compound solvent is -80.9°C, and the freezing point of the electrolyte is -84.0°C.

[0025] The ion conductivity can reach 0.43mS / cm at 25°C...

Embodiment 2

[0028] (1) Under the Dean-Stark apparatus, boric acid and 2-dimethylaminoethanol were dissolved in 100ml xylene in a molar ratio of 1:3.2 and placed in a 250ml round bottom flask, and under reflux Heat for a day. All volatiles were removed from the resulting liquid in a rotary evaporator and high vacuum distillation. A pure transparent organic liquid based on a borate aminoether ligand symmetrical star organic solvent was obtained after passing through an alumina column. Yield 97%.

[0029] (2) 1 g of lithium bistrifluoromethanesulfonimide (LiTFSI) was dissolved in 2.9 g of the above product (boron compound) solvent to prepare a liquid electrolyte solution.

[0030] A polypropylene separator is immersed in an electrolyte solution, and the soaked separator can be used as a liquid electrolyte.

[0031] The freezing point of the pure boron compound solvent is -80.9°C, and the freezing point of the electrolyte is -84.0°C.

[0032] The ion conductivity can reach 0.72mS / cm at 25...

Embodiment 3

[0035] (1) Under the Dean-Stark apparatus, boric acid and 2-dimethylaminoethanol were dissolved in 170ml toluene with a molar ratio of 1:3.2 and placed in a 250ml round bottom flask, and heated under reflux one day. All volatiles were removed from the resulting liquid in a rotary evaporator and high vacuum distillation. A pure transparent organic liquid based on a borate aminoether ligand symmetrical star organic solvent was obtained after passing through an alumina column. Yield 97%.

[0036] (2) 1 g of lithium bistrifluoromethanesulfonimide (LiTFSI) was dissolved in 3.5 g of the above product (boron compound) solvent to prepare a liquid electrolyte solution.

[0037] A polypropylene separator is immersed in an electrolyte solution, and the soaked separator can be used as a liquid electrolyte.

[0038] The freezing point of the pure boron compound solvent is -80.9°C, and the freezing point of the electrolyte is -83.2°C.

[0039] The ion conductivity can reach 1.18mS / cm at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com