Treatment process of rattan used for rattan-weaved products

A technology for processing crafts and woven products, which is applied in the field of rattan processing, can solve the problems of shortening the service life of woven products, cracking and aging of rattan, unfavorable processing and production, etc., achieves good market prospects, enhances oxidation resistance, and enhances toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

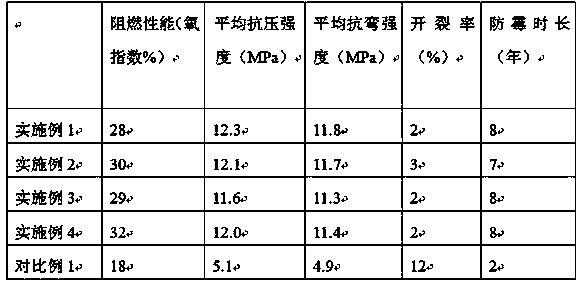

Examples

Embodiment 1

[0024] A treatment process of rattan for rattan products, comprising the steps of:

[0025] (1) Raw material selection: first select vines with vigorous growth and no pests, and then spray regulators on the roots of vines, wherein the regulators are made of the following raw materials in parts by weight: 8 parts of urea, 2 parts of potassium dihydrogen phosphate parts, 3 parts of ferrous sulfate, 0.6 parts of sodium glutamate, 0.4 parts of indole acetic acid, 15 parts of ethylene glycol and 90 parts of distilled water; after 5 days, the rattans were harvested, and the branches, leaves and knots on the rattans were removed, and then Classify and pick rattans in different diameter ranges, among which rattans with a diameter of 0-2cm are classified into category one, rattans with a diameter of 2-5cm are classified into category two, rattans with a diameter of 5-8cm are classified into category Three, and select category two as the experimental object;

[0026] (2) Pretreatment: ...

Embodiment 2

[0032] A treatment process of rattan for rattan products, comprising the steps of:

[0033] (1) Raw material selection: first select vines that grow vigorously and are free from pests, and then spray regulators on the roots of vines, wherein the regulators are made of the following raw materials in parts by weight: 9 parts of urea, 2 parts of potassium dihydrogen phosphate part, 4 parts of ferrous sulfate, 0.7 part of sodium glutamate, 0.4 part of indole acetic acid, 18 parts of ethylene glycol and 100 parts of distilled water; after 6 days, the rattan was harvested, and the branches, leaves and knots on the rattan were removed, and then Classify and pick rattans in different diameter ranges, among which rattans with a diameter of 0-2cm are classified into category one, rattans with a diameter of 2-5cm are classified into category two, rattans with a diameter of 5-8cm are classified into category Three, and select category two as the experimental object;

[0034] (2) Pretreat...

Embodiment 3

[0040] A treatment process of rattan for rattan products, comprising the steps of:

[0041] (1) Raw material selection: first select vines with vigorous growth and no pests, and then spray regulators on the roots of vines, wherein the regulators are made of the following raw materials in parts by weight: 10 parts of urea, 3 parts of potassium dihydrogen phosphate parts, 5 parts of ferrous sulfate, 0.7 parts of sodium glutamate, 0.4 parts of indole acetic acid, 18 parts of ethylene glycol and 110 parts of distilled water; after 7 days, the rattans were harvested, and the branches, leaves and knots on the rattans were removed, and then Classify and pick rattans in different diameter ranges, among which rattans with a diameter of 0-2cm are classified into category one, rattans with a diameter of 2-5cm are classified into category two, rattans with a diameter of 5-8cm are classified into category Three, and select category two as the experimental object;

[0042] (2) Pretreatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com