Polystyrene microsphere

A polystyrene microsphere and microsphere technology, which is applied in the preparation of microspheres, microcapsule preparations, instruments, etc., can solve the problems of low efficiency of PEG surface modification, increased technical difficulty and workload, and not particularly effective, etc. The effect of suppressing non-specific adsorption, simplifying operation, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Preparation of the first nano-scale polystyrene microspheres of the present invention

[0023] This embodiment provides the preparation method of the first nano-scale polystyrene microspheres of the present invention, and the specific preparation steps are as follows:

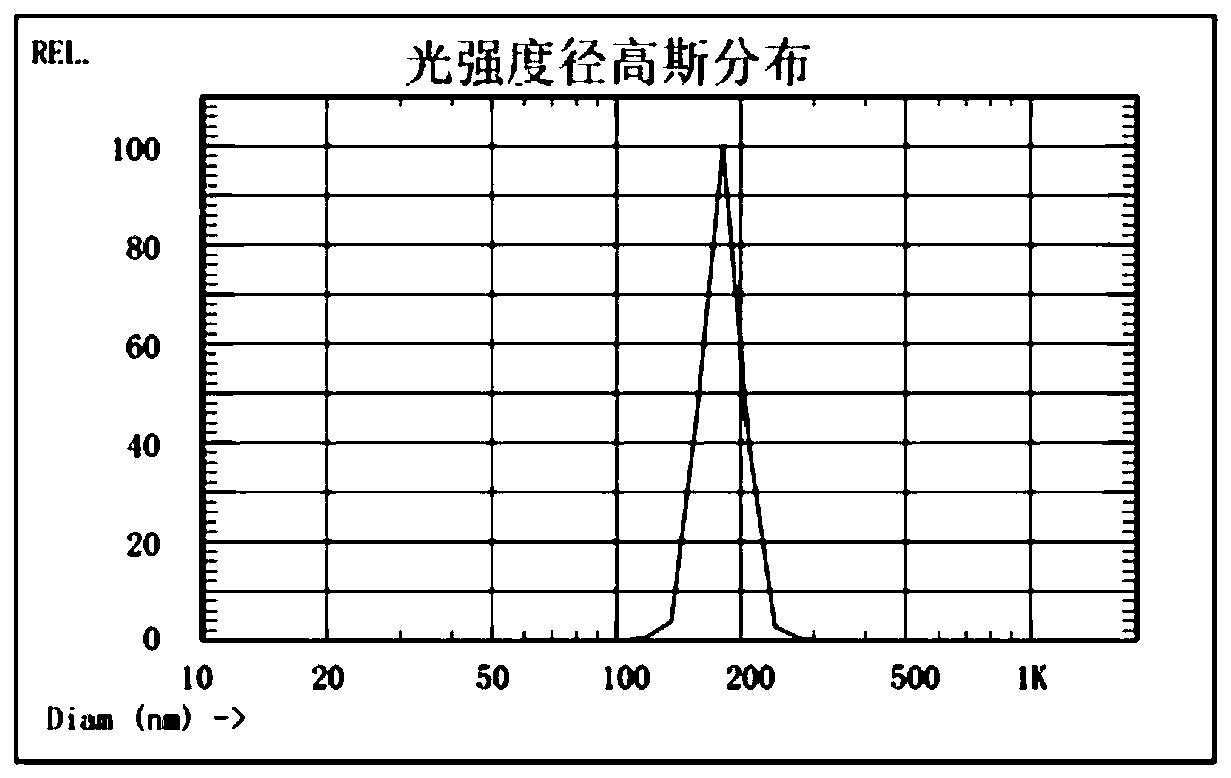

[0024] Synthesis of polystyrene microspheres: take a 250ml round bottom flask, add 86.38g of pure water, 43mg of sodium lauryl sulfate, under the protection of an inert gas, stir at 70°C to obtain a homogeneous solution; add styrene monomer 12.91g, continue to stir for 1 hour, weigh 10mg ammonium persulfate and dissolve it in water, add it to the homogeneous solution obtained above, react at 70°C and 150rpm for 6 hours; centrifuge, remove the supernatant, and finally disperse in 100ml pure water In this method, monodisperse polystyrene microspheres with an average particle diameter of 158 nm were prepared.

[0025] Coating of polystyrene microspheres: In a 200ml beaker, weigh 2.5g Eudragit...

Embodiment 2

[0026] Embodiment 2: the preparation of the second nano-scale polystyrene microsphere of the present invention

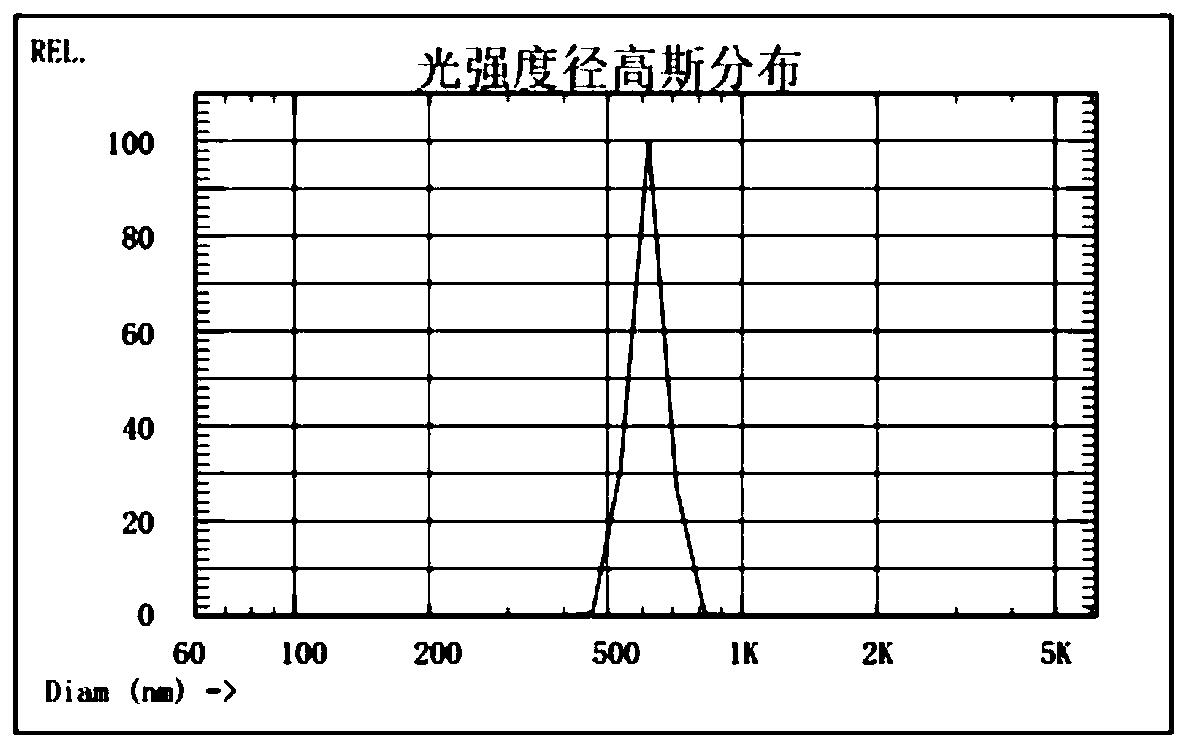

[0027] Synthesis of polystyrene microspheres: Take a 500ml round bottom flask, add 200g of pure water, 0.1g of potassium carbonate, under the protection of an inert gas, stir at 70°C to obtain a homogeneous solution; add 37.5g of styrene monomer, acrylic acid 1.2g, continue to stir for 1 hour, weigh 300mg ammonium persulfate and dissolve it in water, add it to the homogeneous solution obtained above, react at 70°C and 150rpm for 20 hours; centrifuge, remove the supernatant, and finally disperse in 300ml pure water Among them, monodisperse polystyrene microspheres with a particle size of 581nm.

[0028]Coating of polystyrene microspheres: In a 1000ml beaker, weigh 8.0g Eudragit L100-55 and dissolve it in 300ml 0.5M potassium hydroxide solution, and add the polystyrene microspheres synthesized in the first step to disperse solution, stirred for 30 minutes; after full...

Embodiment 3

[0029] Embodiment 3: Preparation of the third micron-sized polystyrene microspheres of the present invention

[0030] This embodiment provides a method for preparing micron-sized polystyrene microspheres with low non-specific adsorption, and the specific steps are as follows:

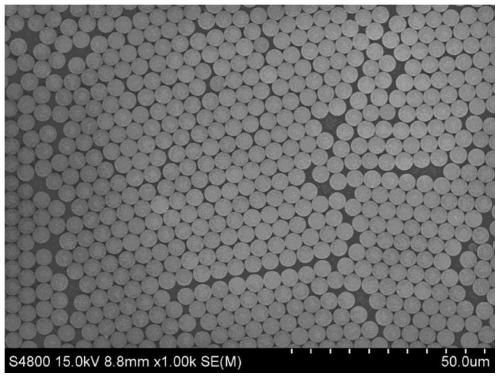

[0031] Take a 500ml round bottom flask, add 12g Eudragit L100-55, 6g dioctyl sodium sulfosuccinate, 100mL ethanol and 200mL ethylene glycol methyl ether, stir to obtain a homogeneous solution; weigh 3.1g benzoyl peroxide As an initiator, dissolve in 62mL of distilled styrene monomer; add the styrene monomer solution dissolved with benzoyl peroxide into the homogeneous solution obtained above, stir, protect with nitrogen, and react at a reaction temperature of 70°C and 150rpm 20 hours; centrifuge, remove the supernatant, then disperse with ethanol, repeat the dispersion six times, and finally disperse in 200mL pure water to obtain micron-sized polystyrene microspheres with a particle size of 4.5 μm and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com