Nanomaterial modified water-based polyisocyanate curing agent and its preparation and application

A technology of polyisocyanate and nanomaterials, which can be applied in biocide-containing paints, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., and can solve problems such as low NCO content, poor medium resistance, and poor appearance of coating films , to achieve the effect of improving the drying speed, excellent matching, and overcoming the slow drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

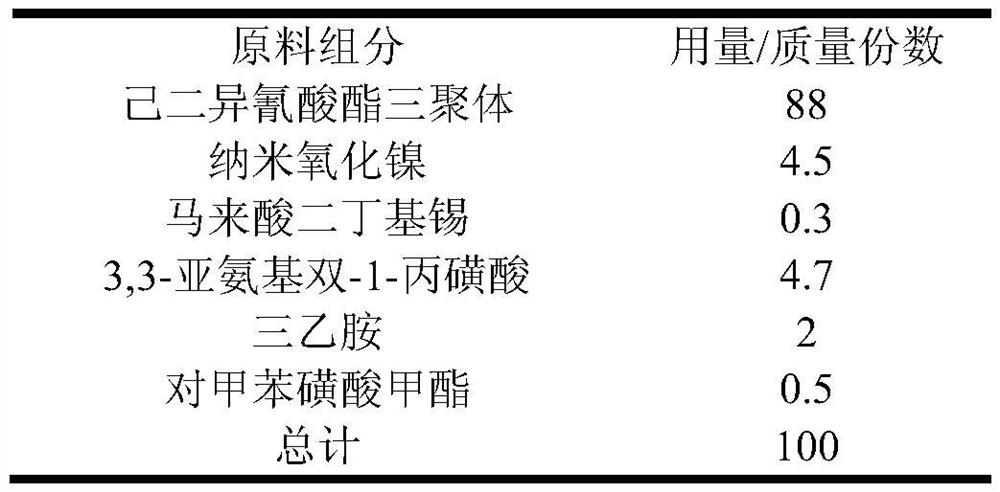

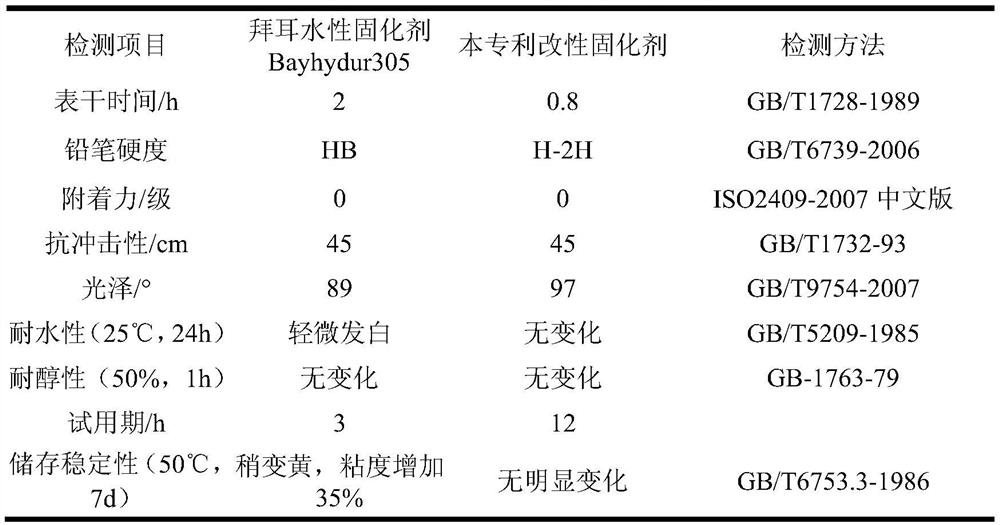

[0031] (1) Preparation of nano-material modified polyisocyanate curing agent, each raw material component and consumption are as follows in Table 1:

[0032] Table 1

[0033]

[0034] Preparation process: under the protection of nitrogen, add 88 parts of hexamethylene diisocyanate trimer and 4.5 parts of nano-nickel oxide to the reaction kettle, ultrasonically disperse for 20-60 minutes, heat up to 50°C, add 0.3 parts of dibutyltin maleate to react for 6 hours, Add 4.7 parts of 3,3-iminobis-1-propanesulfonic acid, drop 2 parts of triethylamine, raise the temperature to 80°C, react for 4 hours until the NCO content of the system reaches the theoretical value, add 0.5 parts of polymerization inhibitor p-toluene Methyl sulfonate terminates the reaction to obtain a nano-material modified water-based polyisocyanate curing agent.

[0035] (2) Performance of nano-material modified water-based polyisocyanate curing agent: a colorless transparent viscous liquid with a viscosity (25...

Embodiment 2

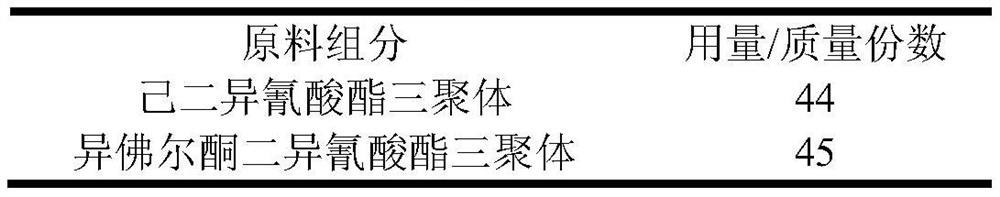

[0042] (1) Preparation and preparation of nano-material modified polyisocyanate curing agent, each raw material and consumption are as follows in Table 3:

[0043] table 3

[0044]

[0045]

[0046] Preparation process: under the protection of nitrogen, add 44 parts of hexamethylene diisocyanate trimer, 45 parts of isophorone diisocyanate trimer, 4.5 parts of nano-cadmium oxide into the reaction kettle, ultrasonically disperse for 60 minutes, heat up to 90 ° C, add 0.3 parts of dibutyltin dilaurate were reacted for 3 hours, 3.7 parts of 3-[(2-sulfoethyl)amino]-1-propanesulfonic acid were added, 2 parts of N,N-dimethylcyclohexylamine were added dropwise, and the temperature was raised to 115°C, react for 8 hours until the NCO content of the system reaches the theoretical value, add 0.5 part of polymerization inhibitor hydroquinone to terminate the reaction, and obtain the nano-material modified water-based polyisocyanate curing agent.

[0047] (2) Properties of nano-mate...

Embodiment 3

[0054] (1) Preparation of nano-material modified water-based polyisocyanate curing agent, each raw material and consumption are as follows in Table 5:

[0055] table 5

[0056]

[0057] Preparation process: under the protection of nitrogen, add 30 parts of toluene diisocyanate trimer, 59 parts of isophorone diisocyanate trimer, 4.5 parts of nano-silver oxide into the reaction kettle, ultrasonically disperse for 30 minutes, heat up to 80 ° C, add React 0.3 parts of stannous octoate for 5 hours, add 3.7 parts of 1,2-propanediol-3-sulfonic acid, add dropwise 2 parts of N,N-dimethylbutylamine, raise the temperature to 100°C, and react for 5 hours until the NCO content of the system reaches the theoretical level value, add 0.5 parts of polymerization inhibitor dimethyl sulfate to terminate the reaction, and obtain the nano-material modified water-based polyisocyanate curing agent.

[0058] (2) Performance of nano-material modified water-based polyisocyanate curing agent: a colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com