A kind of preparation method of hydrogenated modified C5 petroleum resin

A petroleum resin and modification technology, which is applied in the field of petroleum resin, can solve the problems that cannot be used in the field of light-colored and transparent hot-melt adhesives, lack of polar groups, market application restrictions, etc., and achieve excellent compatibility and improved Compatibility, the effect of reducing the difficulty of the hydrogenation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

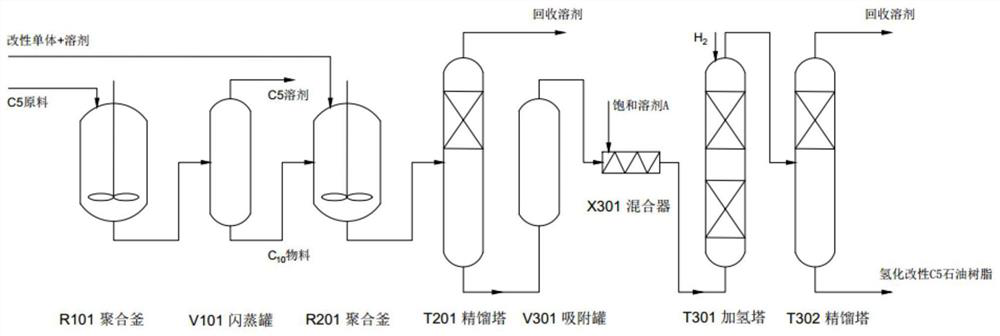

Method used

Image

Examples

Embodiment 1

[0031] In this example, the C5 raw material composition is 3.0wt% isopentene, 5.0wt% cyclopentene, 6.0wt% n-pentene, 6.0wt% isoprene, 8.0wt% cyclopentadiene, piperylene 6.0 wt%, and the rest are saturated C5-C6 alkanes such as isopentane, n-pentane, and cyclopentane.

[0032] Put the C5 raw material into the polymerization kettle R101, polymerize at a temperature of 240°C for 6 hours, and transfer the obtained polymerization liquid into the flash tank V101, and flash at a vacuum degree of -0.085MPa and a temperature of 110°C, unreacted C5 solvent is obtained at the top, and the bottom get C 10 Mixed ingredients. will get C 10The material is conveyed into the polymerization kettle R201, mixed evenly with 4-methylstyrene and xylene at a mass ratio of 1:0.2:0.7, and then reacted at 245°C for 15 hours to obtain a polymerization reaction liquid. Afterwards, the polymerization reaction solution is transported into the rectification tower T201, and rectification is carried out at ...

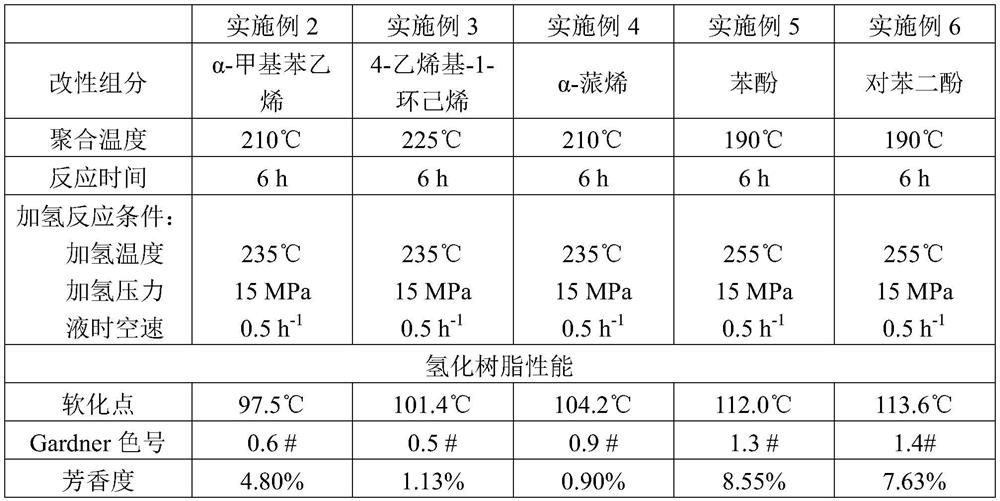

Embodiment 2~6

[0034] In Examples 2-6, the C5 raw material is composed of 2.0wt% isopentene, 5.0wt% cyclopentene, 6.0wt% n-pentene, 4.0wt% isoprene, 6.0wt% cyclopentadiene, and 4.0 wt% of diene, and the rest are saturated C5-C6 alkanes such as isopentane, n-pentane, and cyclopentane. The C5 raw material is polymerized at 230°C for 5 hours, enters the V101 flash tank, and flashes at a vacuum of -0.085MPa and a temperature of 105°C. Unreacted C5 solvent is obtained at the top and C at the bottom. 10 The composition of the mixed material is as follows: C 10 Component tricyclic [5.2.1.0 2,6 ]dec-8-ene content 69.6%, (1Z,5Z)-3,4-dimethyl-1,5-cyclooctadiene content 11.5%, 1-methyl-4-(prop-1-1ene -2-yl) cyclohexene content 10.4%, the rest C 15 The component content is 8.5%.

[0035] C above 10 The mixed material is mixed with different modified monomers and xylene in a mass ratio of 1:0.3:0.7 to obtain a polymerization raw material, which is reacted at a certain temperature to obtain a polymer...

Embodiment 7~10

[0039] with the same ingredient C 10 The material and styrene are mixed in different proportions to obtain the polymerization raw material, which is reacted at a high temperature of 227°C for 10 hours to obtain a petroleum resin liquid, which is then subjected to the same hydrogenation reaction conditions (temperature 230°C, pressure 14.5MPa, liquid space-time Speed 0.5h -1 ) to prepare hydrogenated modified C5 petroleum resin and the performance difference is as follows:

[0040]

[0041] As can be seen from the above examples, when styrene is used as the modified monomer, along with its 10 As the content of the polymerized ingredients increases, the softening point of the hydrogenated modified resin gradually decreases, the color number becomes lighter, and the aromaticity increases linearly; at the same time, the Z-average molecular weight of the resin decreases significantly, which is beneficial to the application in the field of adhesives and rubber mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com