A kind of preparation method of the binder of low ignition point burning resistant semi-coke briquettes

A binder and ignition technology, which is applied in the fuel, solid fuel, petroleum industry and other directions, can solve the problems of lower ignition point, fast combustion rate, non-flammable semi-coke briquette ignition, etc. The effect of ignition difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

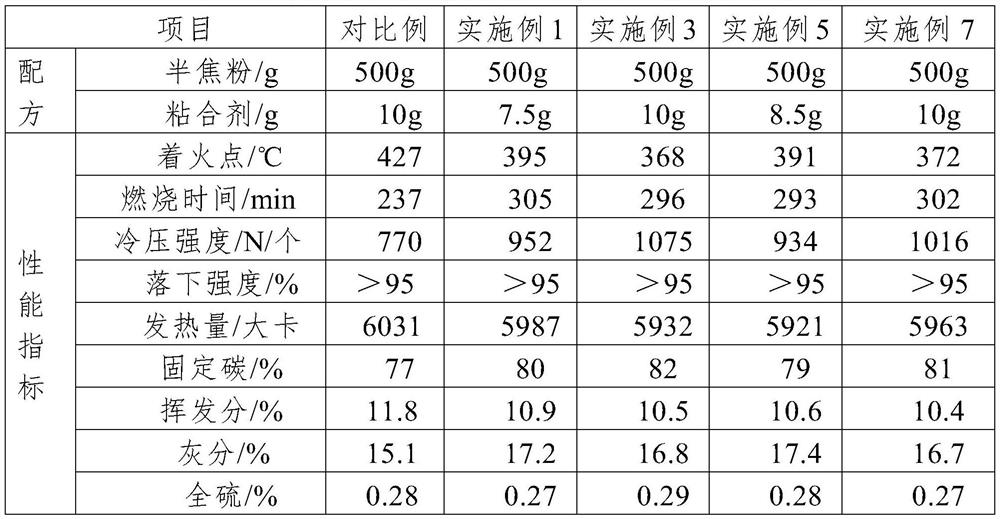

Examples

Embodiment 1

[0024] This embodiment includes the following steps:

[0025] Step 1. Weigh 99.5% of the flake graphite and 0.5% of the phosphorus compound according to the mass percentage, dissolve the weighed phosphorus compound in the ethanol solution first, and then put the weighed flake graphite into the dissolved phosphorus compound After reacting for 65 minutes at a temperature of 90° C., the graphite flakes were taken out and vacuum-dried to obtain modified graphite flakes. The phosphorus-based compound is sodium phosphate, the ethanol solution is an ethanol solution with a mass concentration of 95%, and the ratio of the total volume of the phosphorus-based compound and flake graphite to the volume of the ethanol solution is 1:1.

[0026] Step 2. Take 83% of the polymer carbon-based mixture and 17% of the modified flake graphite obtained in step 1 according to the mass percentage, and put the weighed polymer carbon-based mixture and the modified flake graphite into the mixer After mi...

Embodiment 2

[0028] This embodiment includes the following steps:

[0029] Step 1. Weigh 99.7% of the flake graphite and 0.3% of the phosphorus compound according to the mass percentage, dissolve the weighed phosphorus compound in the ethanol solution, and then put the weighed flake graphite into the dissolved phosphorus compound After reacting for 50 minutes at a temperature of 85° C. in ethanol solution, the graphite flakes were taken out and vacuum-dried to obtain modified graphite flakes. The phosphorus compound is ammonium phosphate, the ethanol solution is an ethanol solution with a mass concentration of 95%, and the ratio of the total volume of the phosphorus compound and flake graphite to the volume of the ethanol solution is 1:1.

[0030] Step 2. Weigh 85% of the polymer carbon-based mixture and 15% of the modified flake graphite obtained in step 1 according to the mass percentage, and put the weighed polymer carbon-based mixture and the modified flake graphite into the mixer Aft...

Embodiment 3

[0032] This embodiment includes the following steps:

[0033] Step 1. Weigh 99.5% of the flake graphite and 0.5% of the phosphorus compound according to the mass percentage, dissolve the weighed phosphorus compound in the ethanol solution first, and then put the weighed flake graphite into the dissolved phosphorus compound After reacting for 55 minutes at a temperature of 80° C., the graphite flakes were taken out and vacuum-dried to obtain modified graphite flakes. Described phosphorus compound is ammonium phosphate and sodium phosphate (mass ratio 1:1), and described ethanol solution is the ethanol solution that mass concentration is 95%, and the total volume of described phosphorus compound and flake graphite and described ethanol solution The volume ratio is 1:1.

[0034] Step 2. Take 83% of the polymer carbon-based mixture and 17% of the modified flake graphite obtained in step 1 according to the mass percentage, and put the weighed polymer carbon-based mixture and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com