Red fluorescence nanofiber with piezoelectric function and preparation method of red fluorescence nanofiber with piezoelectric function

A technology of red fluorescence and nanofibers, which is applied to the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of low content of β crystals, no fluorescence, and poor piezoelectric properties of nanofibers, so as to improve the quality of β crystals. content, the effect of excellent piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

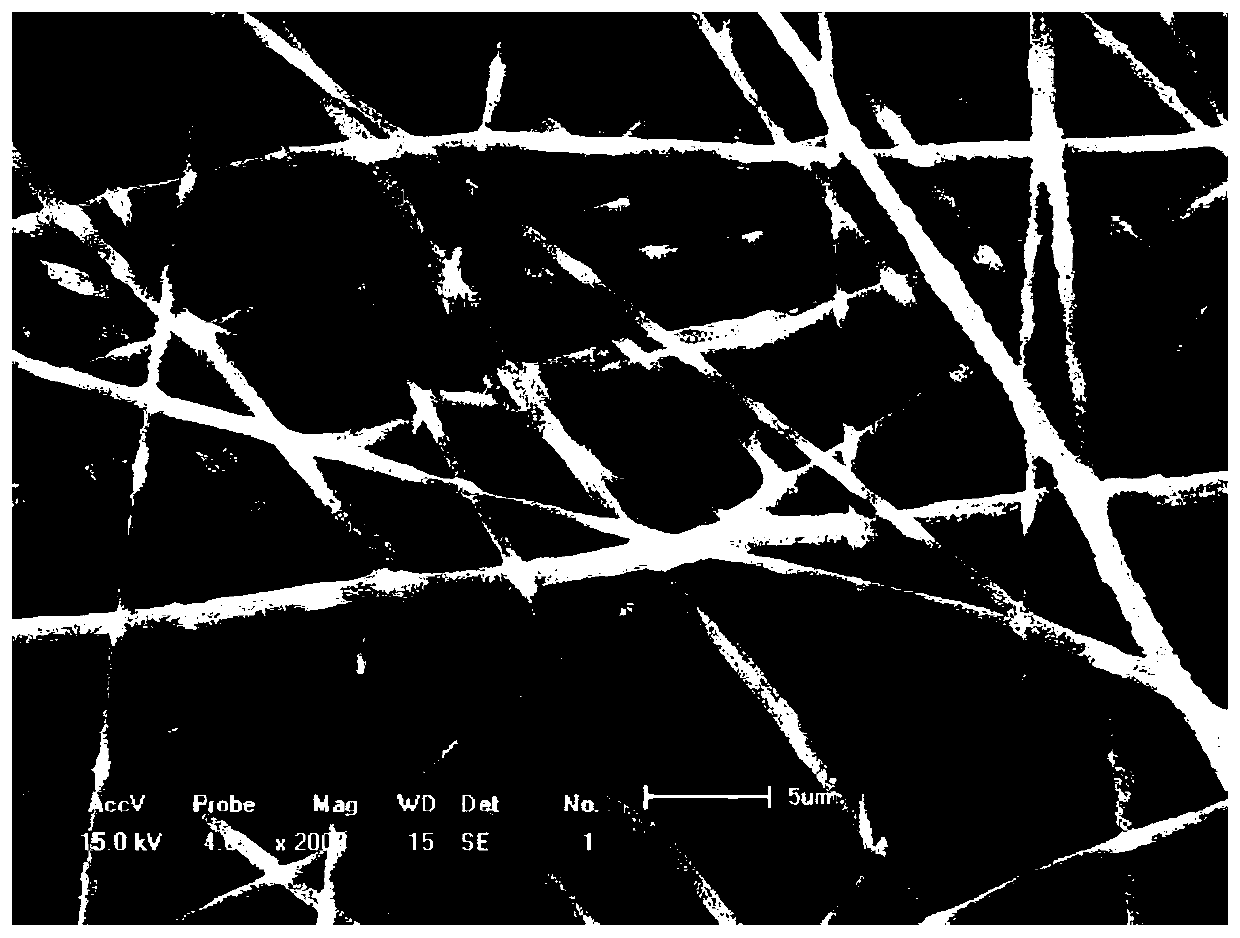

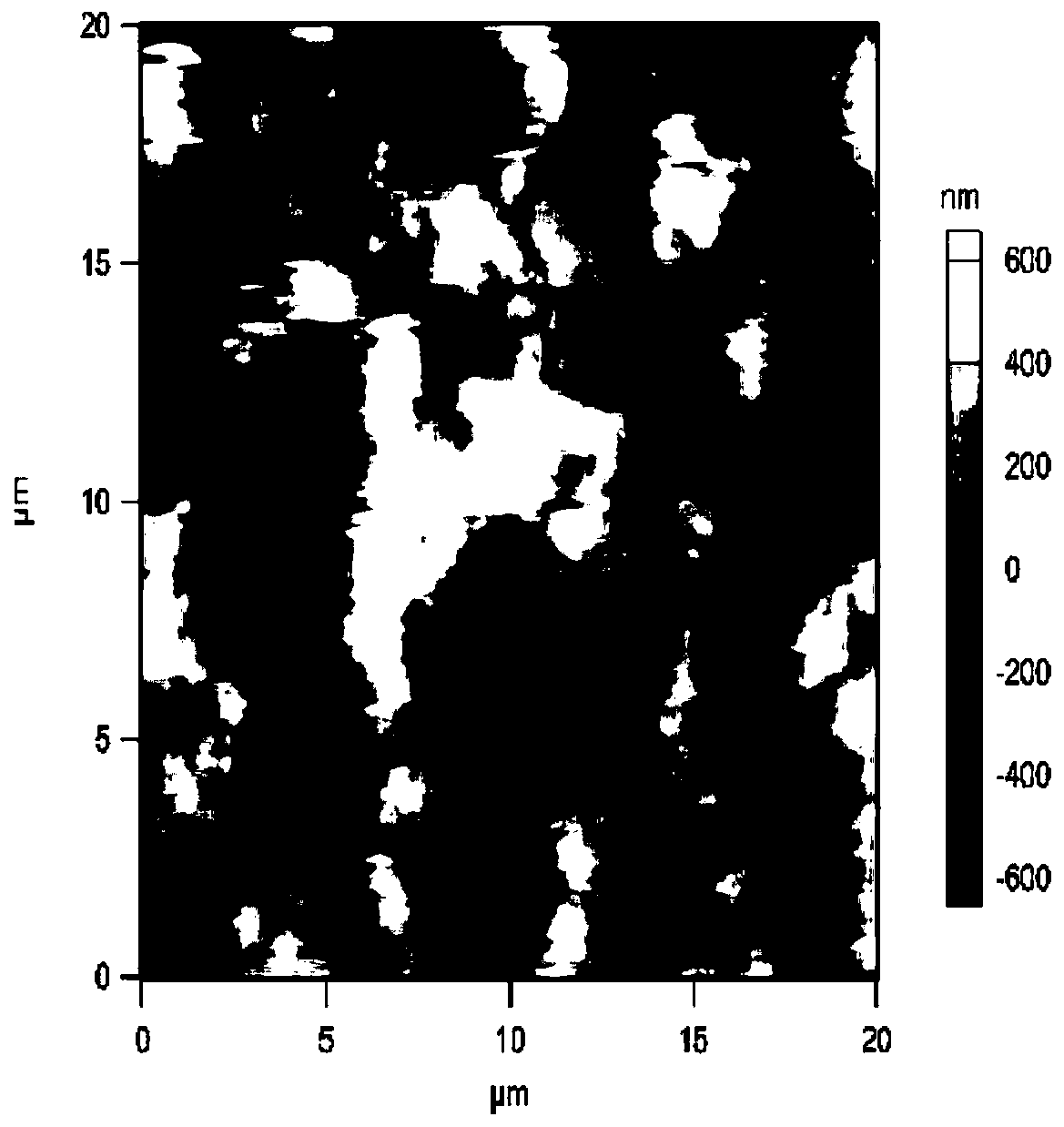

[0025] A nanofiber with red fluorescence and piezoelectric function, the preparation method thereof may specifically include the following steps:

[0026] Step A, according to the molar ratio of the first component: 2-thienoyltrifluoroacetone (TTA): the second component=0.5~2:1~3:1~3, the first component, 2-thiophene Formyl trifluoroacetone and the second component are respectively dissolved in absolute ethanol and mixed together, after stirring for 12 to 24 hours, the resulting precipitate is washed with water and ethanol in sequence, and then dried to obtain a red fluorescent rare earth complex thing.

[0027] Step B, dissolving polyvinylidene fluoride (PVDF) with an average molecular weight of 53400 in the third component, and then adding acetone (AC) to stir and mix to obtain a mixed solution of polyvinylidene fluoride; according to the red fluorescent rare earth complex : The mass ratio of the polyvinylidene fluoride=1-5:10, dissolving the red fluorescent rare earth comp...

Embodiment approach

[0030] (1) In step A, the first component is europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O) or europium chloride hexahydrate (EuCl 3 ·6H 2 O) at least one; the second component is at least one of o-phenanthroline (Phen) or triphenylphosphine (TPPO).

[0031] (2) In step B, the third component is at least one of dimethylsulfoxide (DMSO) or N,N-dimethylformamide (DMF). In the polyvinylidene fluoride mixed solution, the mass concentration of polyvinylidene fluoride is 10%-18%, and the volume ratio of the third component to acetone is 2:8-8:2.

[0032] (3) In step B, the mass ratio of the red fluorescent rare earth complex to the polyvinylidene fluoride is 1-5:10, preferably 4-5:10; when the red fluorescent rare earth complex is mixed with the When the mass ratio of polyvinylidene fluoride is 4-5:10, the fluorescence properties of the finally prepared nanofibers are significantly better than other ratios. By adjusting the mass ratio of the red fluorescent rare earth comp...

Embodiment 1

[0038] A nanofiber with red fluorescence and piezoelectric function, the preparation method thereof may specifically include the following steps:

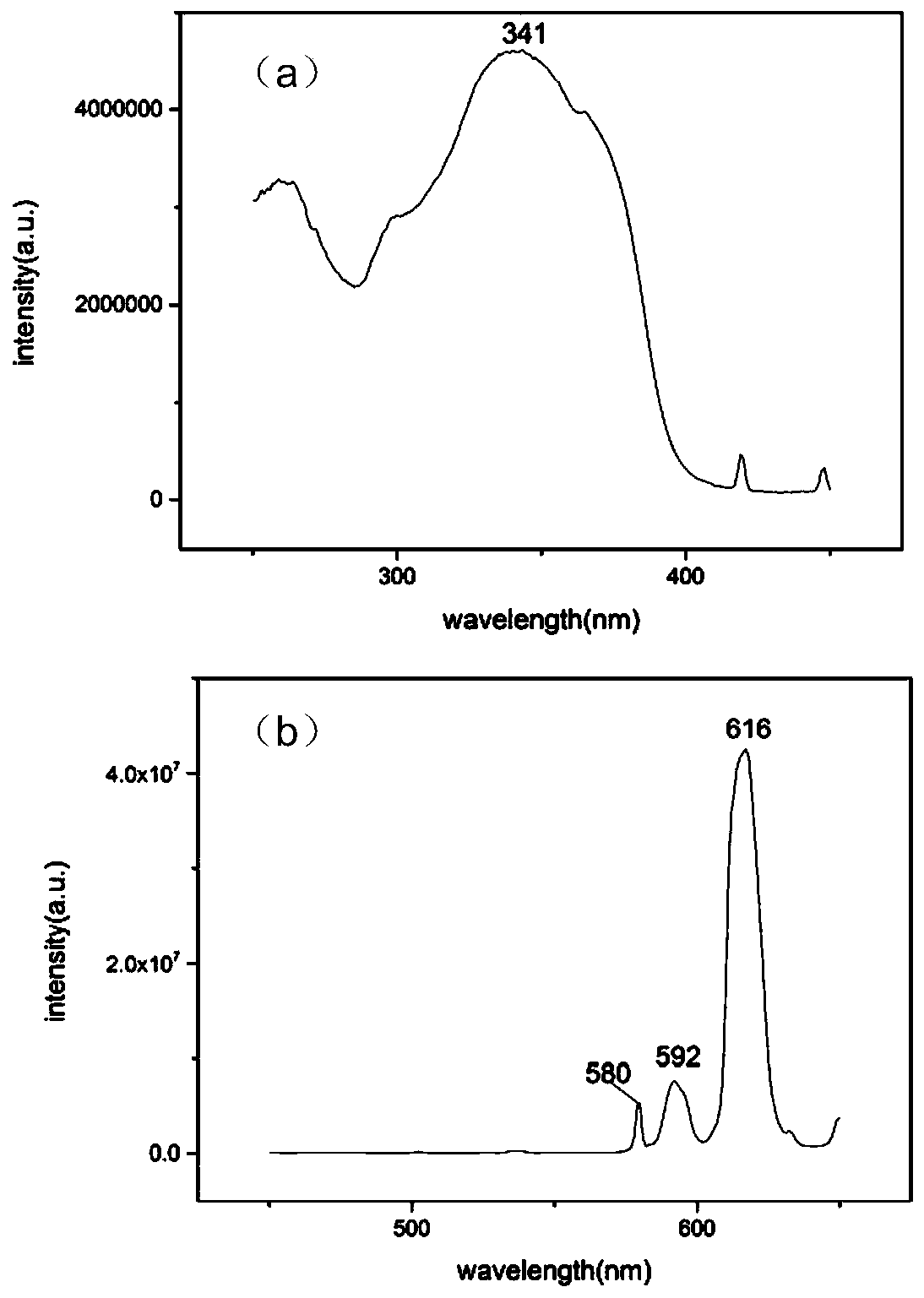

[0039] Step a1, according to europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O): 2-thienoyltrifluoroacetone (TTA): o-phenanthroline (Phen) = 1:3:1 molar ratio, weigh 2.2305g of Eu(NO 3 ) 3 ·6H 2 The TTA of O, 3.3327g, the Phen of 0.9011g; Dissolve Eu(NO with 5ml absolute ethanol 3 ) 3 ·6H 2 O, then dissolve TTA and Phen with 6ml of absolute ethanol, add NaOH solution dropwise in the TTA that dissolves, adjust the pH value to 6~7; Then dissolve the Eu(NO 3 ) 3 ·6H 2 O and Phen were added dropwise to TTA, and after magnetic stirring for 12 hours, the precipitate was filtered with a funnel, washed, put into an oven, heated to 80°C and dried under vacuum to obtain a red fluorescent rare earth complex . The red fluorescent rare earth complex is Eu(TTA) 3 Phen, emits the characteristic red fluorescence of europium under ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com