A kind of preparation method of spinnable silica-alumina sol

A technology of silica-alumina sol and acid silica sol, which is applied to the preparation of aluminum hydroxide, chemical instruments and methods, silicon compounds, etc., can solve the problems of aluminum sol not having spinnability, etc., and achieve low cost, simple process, and reduced energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of spinnable silica-alumina sol, comprising steps as follows:

[0049] (1) Preparation of Aluminum Hydroxide Suspension

[0050] 1500g AlCl 3 ·6H 2 Dissolve O in 10L of triple distilled water, add 1270g of ammonia water with a mass fraction of 25%, stir evenly, react at 20-25°C for 2.0h, filter the reaction product, wash the filter cake with triple distilled water until the conductivity of the filtrate is 1.38mS / cm to obtain amorphous aluminum hydroxide, which is then added to water to obtain a suspension with a solid content of 5.6%;

[0051] (2) Preparation of aluminum sol

[0052] Add 325g of formic acid solution and 373g of acetic acid to the suspension obtained in step (1) and stir, react at 35-40°C for 8h to obtain a uniform and transparent aluminum sol with a pH value of 4.0 and a solid content of 5%;

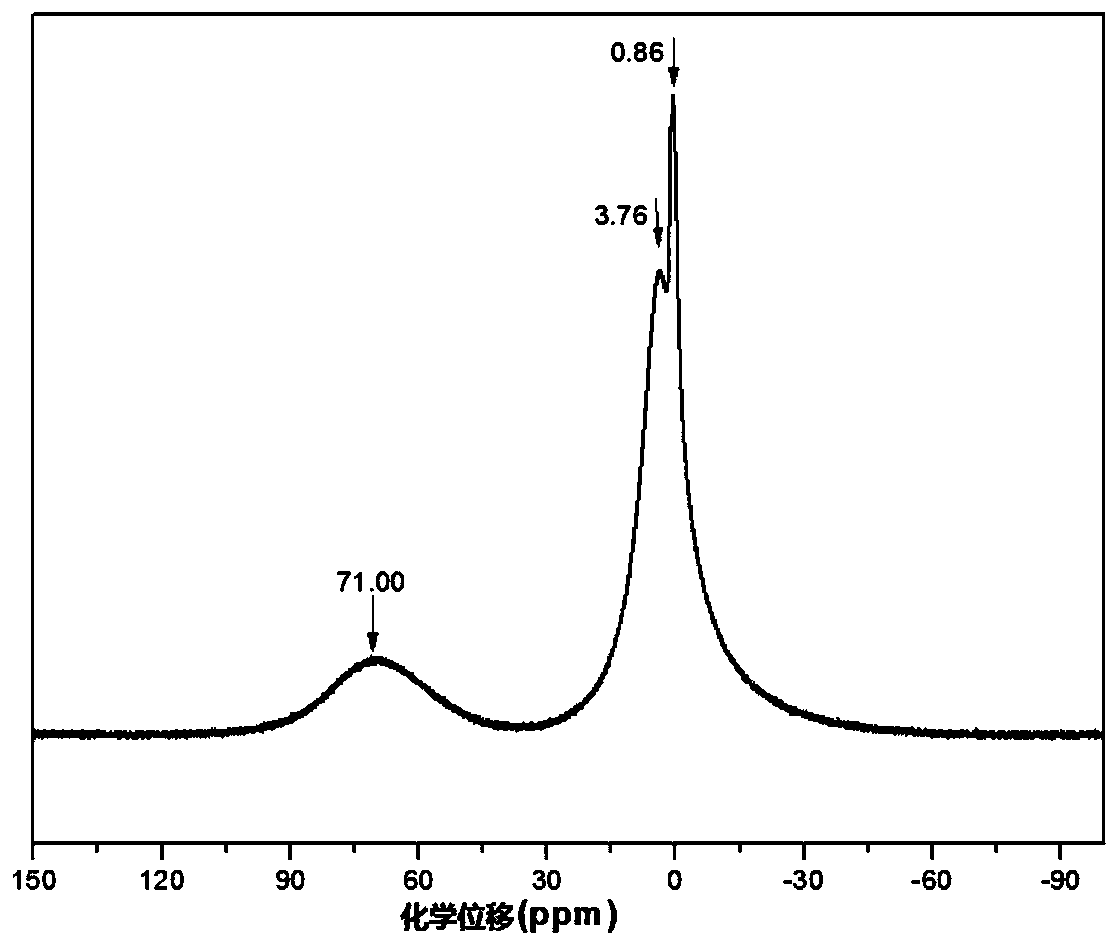

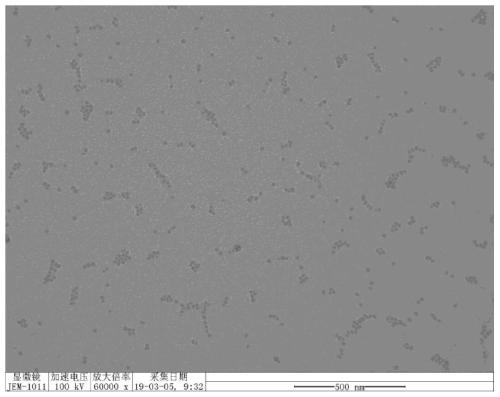

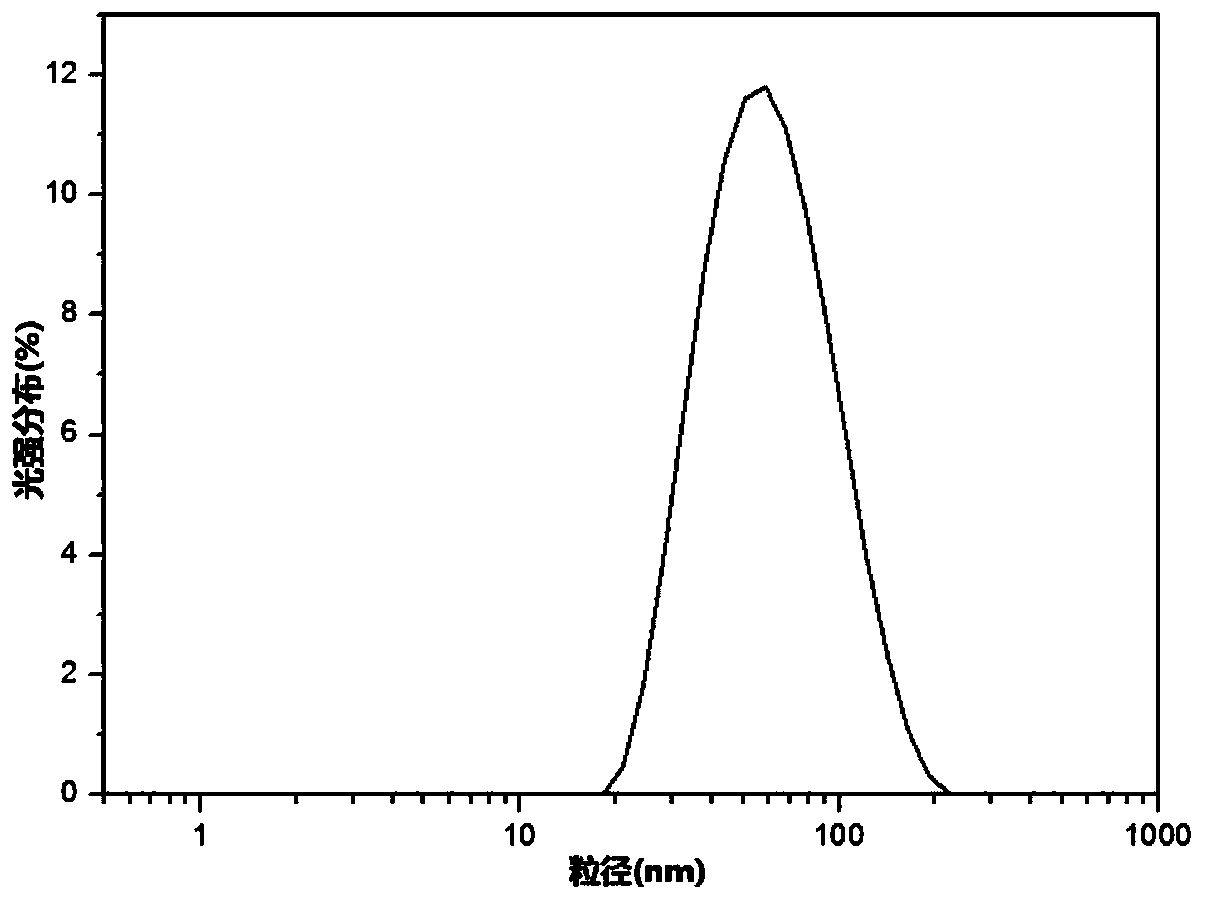

[0053] (3) Preparation of spinnable silica-alumina sol

[0054] 6330g of aluminum sol obtained in step (2) and 821.1g of newly prepared...

Embodiment 2

[0062] A preparation method of spinnable silica-alumina sol, comprising steps as follows:

[0063] (1) Preparation of Aluminum Hydroxide Suspension

[0064] With embodiment 1;

[0065](2) Preparation of aluminum sol

[0066] Add 162.4g of formic acid solution and 559.4g of acetic acid to the suspension obtained in step (1), stir, and react at 35-40°C for 8h to obtain a uniform and transparent aluminum sol with a solid content of 5.0% and a pH value of 3.9;

[0067] (3) Preparation of spinnable silica-alumina sol

[0068] 6354g of the aluminum sol obtained in step (2) and 821.1g of the newly prepared solid content of 15% acidic silica sol are uniformly mixed at 35°C to obtain a mixed sol, and the mixed sol is at 40°C and a vacuum of 0.095MPa. The mixed sol was aged to a viscosity of 20 Pa·s to obtain a spinnable silica-alumina sol.

[0069] The above-mentioned spinnable silica-alumina sol is centrifuged to obtain gel fiber cotton. The process conditions are as follows: the ...

Embodiment 3

[0071] A preparation method of spinnable silica-alumina sol, comprising steps as follows:

[0072] (1) Preparation of Aluminum Hydroxide Suspension

[0073] 1500g AlCl 3 ·6H 2 O was dissolved in 10.5L of triple distilled water. After complete dissolution, 1863.88g of 40% sodium hydroxide solution was added, stirred evenly, and reacted at 30-35°C for 2.5h. Wash until the conductivity of the filtrate is 1.42mS / cm to obtain amorphous aluminum hydroxide, which is then added to triple distilled water to obtain a suspension with a solid content of 7.5%;

[0074] (2) Preparation of aluminum sol

[0075] Add 487.2g of formic acid solution and 186.5g of acetic acid to the suspension obtained in step (1), stir, and react at 45-50°C for 9.5h to obtain a uniform and transparent aluminum sol with a solid content of 6.5% and a pH value of 4.0;

[0076] (3) Preparation of spinnable silica-alumina sol

[0077] Mix 4877g of aluminum sol obtained in step (2) with 905.6g of newly prepared a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com