Method for modifying polyolefin lithium-ion battery separator

A polyolefin diaphragm and modification technology, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of not introducing heat-resistant materials and increasing the resistance of the diaphragm, so as to increase the surface roughness and shrinkage of the film Effect of reducing and increasing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Pretreatment of the diaphragm

[0022] Corona treatment was performed on the PE separator fully washed with deionized water and ethanol, with a power of 0.1W and a treatment time of 20s to make the surface negatively charged.

[0023] 2) In situ self-assembly to construct organic-inorganic hybrid composite layer

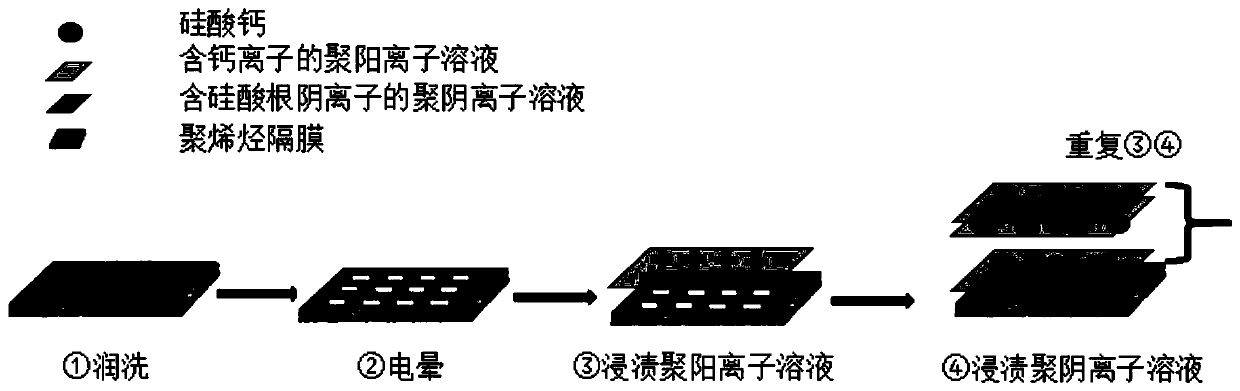

[0024] as attached figure 1 As shown, soak the PE diaphragm pretreated in step 1) in chitosan-calcium chloride solution (chitosan concentration 0.1g / L, calcium chloride concentration 0.075mol / L) for 20min, take it out and wash it, and then Soak in polyacrylic acid-sodium silicate solution (polyacrylic acid concentration 0.1g / L, sodium silicate concentration 0.075mol / L) for 20min, take it out and wash it. An organic / inorganic hybrid composite layer is constructed on the surface of the PE separator.

[0025] 3) Post-treatment of modified diaphragm

[0026] The PE separator containing the organic / inorganic hybrid composite layer obtained in step 2) was fur...

Embodiment 2

[0028] 1) Pretreatment of the diaphragm

[0029] Corona treatment was performed on the PE separator fully washed with deionized water and ethanol, with a power of 1W and a treatment time of 6s to make its surface negatively charged.

[0030] 2) In situ self-assembly to construct organic-inorganic hybrid composite layer

[0031] as attached figure 1 As shown, soak the PE diaphragm pretreated in step 1) in chitosan-calcium chloride solution (chitosan concentration 1g / L, calcium chloride concentration 0.04mol / L) for 20min, take it out and wash it, and then dip it Put it in polyacrylic acid-sodium silicate solution (polyacrylic acid concentration 1g / L, sodium silicate concentration 0.04mol / L) for 20min, take it out and wash it. Step 2) was repeated, and two layers of organic / inorganic hybrid composite layers were constructed on the surface of the PE separator.

[0032] 3) Post-treatment of modified diaphragm

[0033] The PE separator containing the organic / inorganic hybrid com...

Embodiment 3

[0035] 1) Pretreatment of the diaphragm

[0036] The PP separator fully washed with deionized water and ethanol was subjected to corona treatment with a power of 1.5W and a treatment time of 8s to make the surface negatively charged.

[0037] 2) In situ self-assembly to construct organic-inorganic hybrid composite layer

[0038] as attached figure 1 As shown, soak the PP diaphragm pretreated in step 1) in chitosan-polyacrylic acid solution (chitosan concentration 0.5g / L, calcium chloride concentration 0.09mol / L) for 20min, take it out and wash it, and then dip it Put it in polyacrylic acid-sodium silicate solution (polyacrylic acid concentration 0.5g / L, sodium silicate concentration 0.09mol / L) for 20min, take it out and wash it. An organic / inorganic hybrid composite layer is constructed on the surface of the PP separator.

[0039] 3) Post-treatment of modified diaphragm

[0040] The PP separator containing the organic / inorganic hybrid composite layer obtained in step 2) wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com