A kind of macromolecular nucleating agent for rapid crystallization of polylactic acid and using method thereof

A technology of macromolecules and nucleating agents, applied in the field of macromolecular nucleating agents, can solve the problems of degradability and partial mechanical properties of polylactic acid resin, low crystallinity of polylactic acid, influence of polylactic acid performance, etc. Value and commercial prospects, effect of low degradability, low investment in processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Preparation of bio-based polyamide polymers:

[0045] (1) Add 100g of undecylenic acid methyl ester and 1g of 1,3-diamino-propanol into 4ml of tetrahydrofuran; after passing through argon for half an hour, place it in an oil bath at 40°C, add 10ml of sodium methoxide, React at 40°C for 20 hours, and then recrystallize to obtain a white powdery solid, which is the desired functional polyamide monomer 1;

[0046] (2) Take 54g of functional polyamide monomer A, 12g of butyric anhydride, and 40mg of dimethylaminopyridine in a round-bottomed flask, add 3ml of tetrahydrofuran to mix, and react at 50°C for 10 hours to obtain a clear solution. The functional polyamide obtained after purification Amide monomer 2;

[0047](3) 1350mg of functional polyamide monomer 2, 150mg of functional polyamide monomer 1, 200mg of oxadithiol, and 10mg of azobisisobutyronitrile catalyst and 10ml of tetrahydrofuran are added to the reaction vessel; After that, the mixture was placed in an oil b...

Embodiment 1

[0052] 1) Dry 100 parts of polylactic acid in a vacuum oven at 40°C for 12 hours for subsequent experiments;

[0053] 2) Add 100 parts of polylactic acid obtained in step 1) into an internal mixer, and blend for 3 minutes at a temperature of 160° C. at a speed of 40 revolutions per minute to mix the various materials uniformly to obtain Polylactic acid resin.

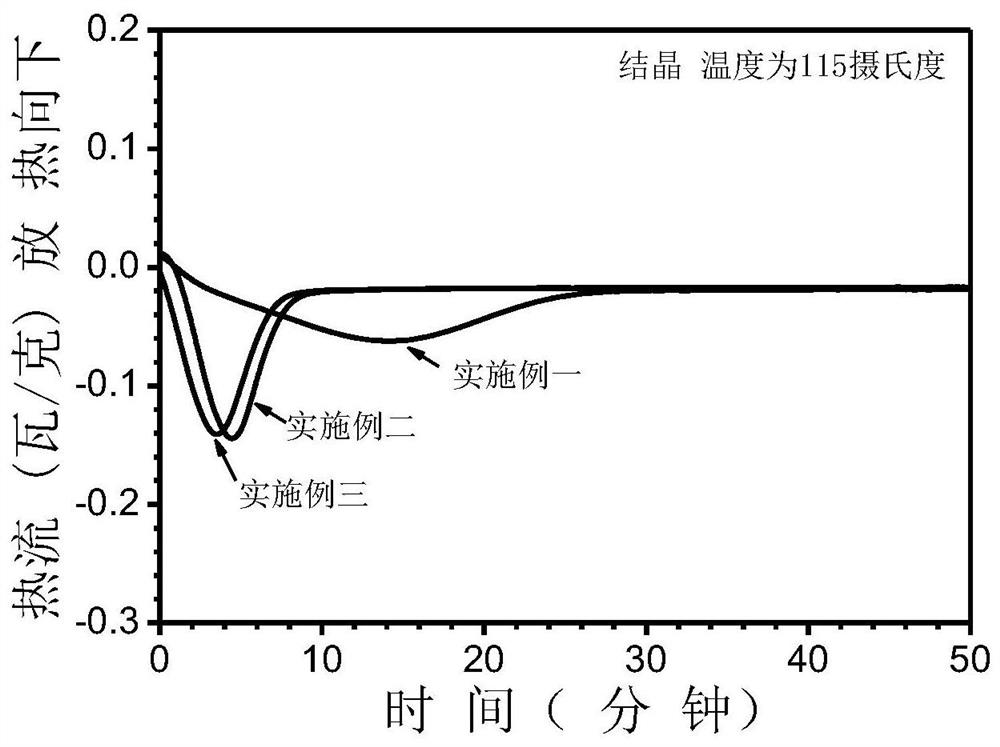

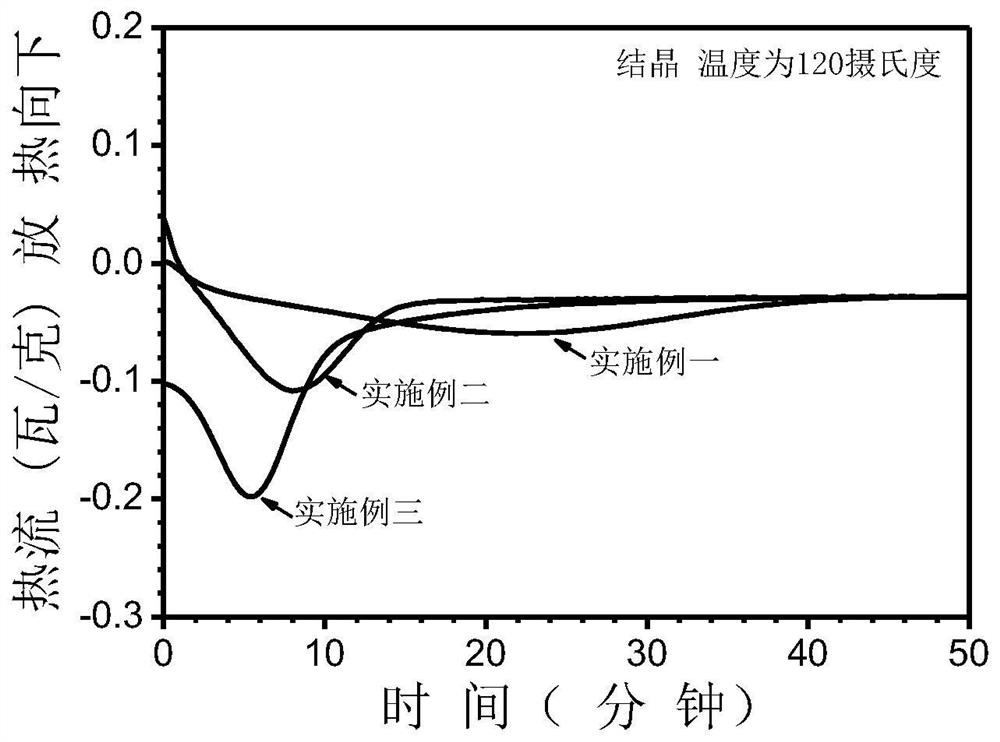

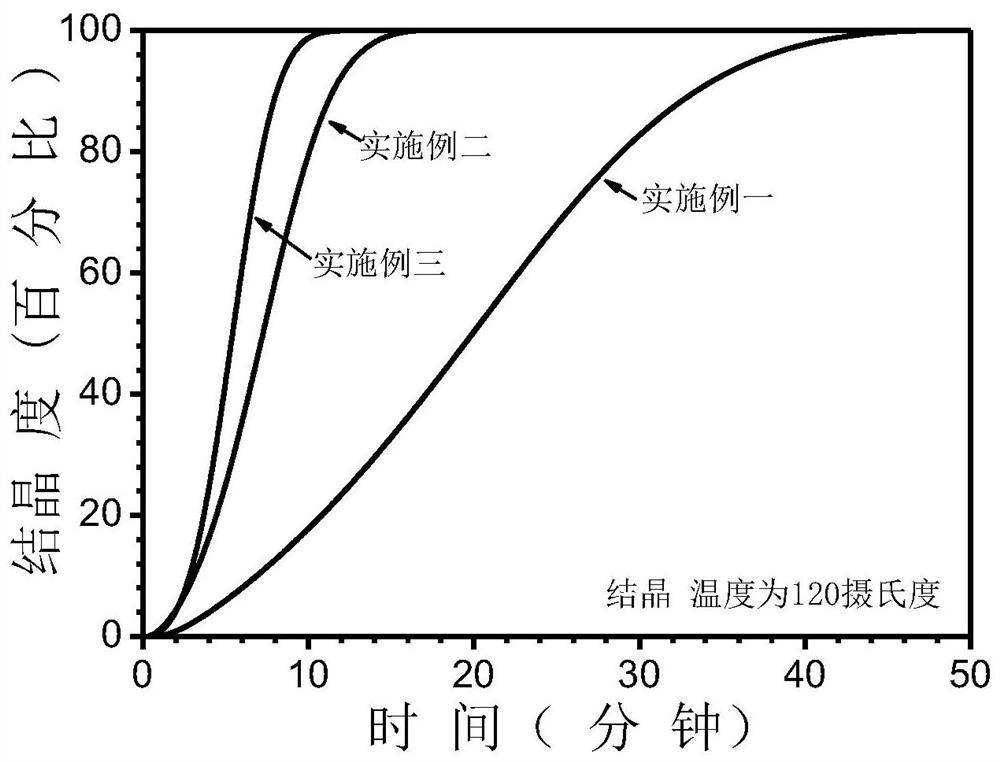

[0054] The polylactic acid resin obtained in Example 1 was subjected to an isothermal crystallization test, and the relationship between the heat flow and the crystallization time of the isothermal crystallization at 115° C. in Example 1 was as follows figure 1 Shown, embodiment 1 in 120 ℃ isothermal crystallization heat flow and crystallization time relation are as follows figure 2 Shown, the crystallinity and crystallization time relation of embodiment 1 at 120 ℃ isothermal crystallization are as follows image 3 shown.

Embodiment 2

[0056] 1) Dry 99.5 parts of polylactic acid and 0.5 parts of macromolecular nucleating agent in a vacuum oven at 100°C for 4 hours for subsequent experiments;

[0057] 2) Mix 99.5 parts of polylactic acid and 0.5 parts of macromolecular nucleating agent in the pretreatment material obtained in step 1) and add them to the internal mixer. Mix various materials uniformly in 20 minutes to obtain rapid crystallization polylactic acid resin.

[0058] The rapid crystallization polylactic acid resin obtained in Example 2 is subjected to an isothermal crystallization test, and the relationship between the heat flow and the crystallization time of the isothermal crystallization at 115°C in Example 2 is as follows figure 1 Shown, embodiment 2 is in 120 ℃ of isothermal crystallization heat flow and crystallization time relation as follows figure 2 Shown, the crystallinity and crystallization time relation of embodiment 2 at 120 ℃ isothermal crystallization are as follows image 3 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com