Corrosion inhibitor for ethylene chemical engineering

A corrosion inhibitor and chemical technology, applied in the field of corrosion inhibitors for ethylene chemical industry, can solve the problems of unfriendly environment, poor anti-corrosion effect of corrosion inhibitors, and generation of harmful substances, etc., to achieve corrosion inhibition speed and good corrosion inhibition performance , good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

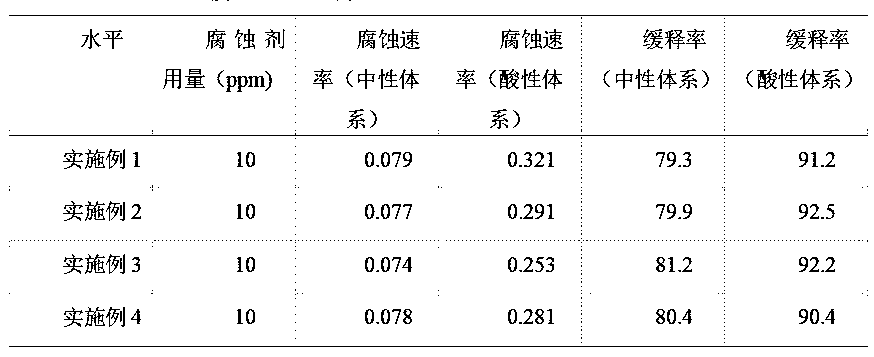

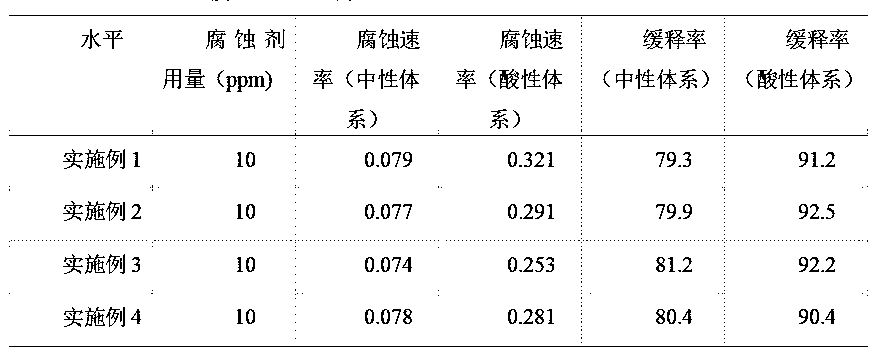

Examples

Embodiment 1

[0020] Sodium silicate 15%, acrylic acid 3%%, hydroxyethylidene diphosphate 1%, mercaptobenzothiazole 5%, benzotriazole 16%, oleic acid 10%, ethylenediamine 10%, diethylenetriamine 11%, imidazoline 12%, alkanol 1%, quaternary ammonium salt 1%, acetylenic alcohol 2%

[0021] Preparation method: Weigh sodium silicate, hydroxyethylidene diphosphate, mercaptobenzothiazole, benzotriazole, imidazoline and oleic acid, then mix sodium silicate, hydroxyethylidene diphosphate, mercaptobenzothiazole, benzene And triazole, imidazoline and oleic acid undergo dehydration condensation reaction to generate compound imidazoline, wherein the temperature of vacuum dehydration in the dehydration condensation reaction is 150°C, and the reaction time is 5h; compound imidazoline, ethylenediamine, alkylamine Base alcohol and alkylamino alcohol are mixed according to the ratio of 1:2:1:2, and the temperature is raised to 70-80°C while stirring, and the heating reaction is carried out for 2 hours; 70% ...

Embodiment 2

[0023] Sodium silicate 17%, acrylic acid 5%, hydroxyethylidene diphosphate 3%, mercaptobenzothiazole 7%, benzotriazole 20%, oleic acid 15%, ethylenediamine 13%, diethylenetriamine 16% , imidazoline 17%, alkanol 3%, quaternary ammonium salt 2%, acetylenic alcohol 4%.

[0024] Preparation method: Weigh sodium silicate, hydroxyethylidene diphosphate, mercaptobenzothiazole, benzotriazole, imidazoline and oleic acid, then mix sodium silicate, hydroxyethylidene diphosphate, mercaptobenzothiazole, benzene And triazole, imidazoline and oleic acid undergo dehydration condensation reaction to generate compound imidazoline, wherein the temperature of vacuum dehydration in the dehydration condensation reaction is 150°C, and the reaction time is 5h; compound imidazoline, ethylenediamine, alkylamine Base alcohol and alkylamino alcohol are mixed according to the ratio of 1:2:1:2, and the temperature is raised to 70-80°C while stirring, and the heating reaction is carried out for 2 hours; 70%...

Embodiment 3

[0026] Sodium silicate 18%, acrylic acid 6%, hydroxyethylidene diphosphate 4%, mercaptobenzothiazole 8%, benzotriazole 23%, oleic acid 18%, ethylenediamine 14%, diethylenetriamine 18% , imidazoline 118%, alkanol 4%, quaternary ammonium salt 2.5%, acetylenic alcohol 5%.

[0027] Preparation method: Weigh sodium silicate, hydroxyethylidene diphosphate, mercaptobenzothiazole, benzotriazole, imidazoline and oleic acid, then mix sodium silicate, hydroxyethylidene diphosphate, mercaptobenzothiazole, benzene And triazole, imidazoline and oleic acid undergo dehydration condensation reaction to generate compound imidazoline, wherein the temperature of vacuum dehydration in the dehydration condensation reaction is 150°C, and the reaction time is 5h; compound imidazoline, ethylenediamine, alkylamine Base alcohol and alkylamino alcohol are mixed according to the ratio of 1:2:1:2, and the temperature is raised to 70-80°C while stirring, and the heating reaction is carried out for 2 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com