Iron copper oxide and its preparation method and application

An oxide, iron and copper technology, applied in the field of environmental treatment, can solve problems such as low catalytic efficiency, and achieve the effects of high catalytic efficiency, good application prospects and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

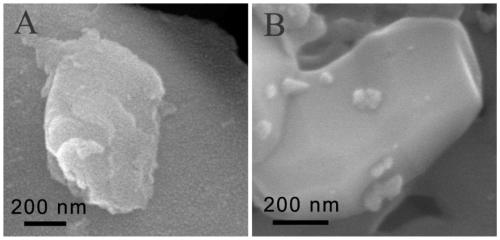

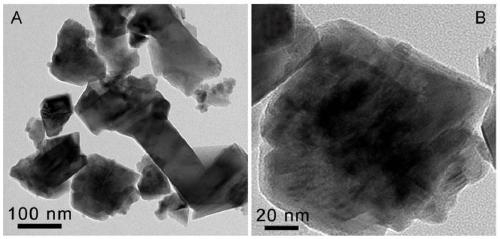

[0040] An iron-copper oxide is prepared by reacting potassium ferricyanide solution and copper chloride solution through heat treatment, which specifically includes the following steps:

[0041] (1) Mix 1 L of potassium ferricyanide solution with a concentration of 20 mM and 1 L of copper chloride solution with a concentration of 40 mM, magnetically stir for 2 hours, and centrifuge to obtain the iron-copper oxide precursor.

[0042] (2) The iron-copper oxide precursor obtained in step (1) was reacted at 550° C. for 2 hours to obtain iron-copper oxide, numbered as CuFeO.

[0043] An application of the iron-copper oxide in this embodiment in the treatment of antibiotic wastewater, specifically the use of iron-copper oxide to remove sulfamethazine in water, includes the following steps:

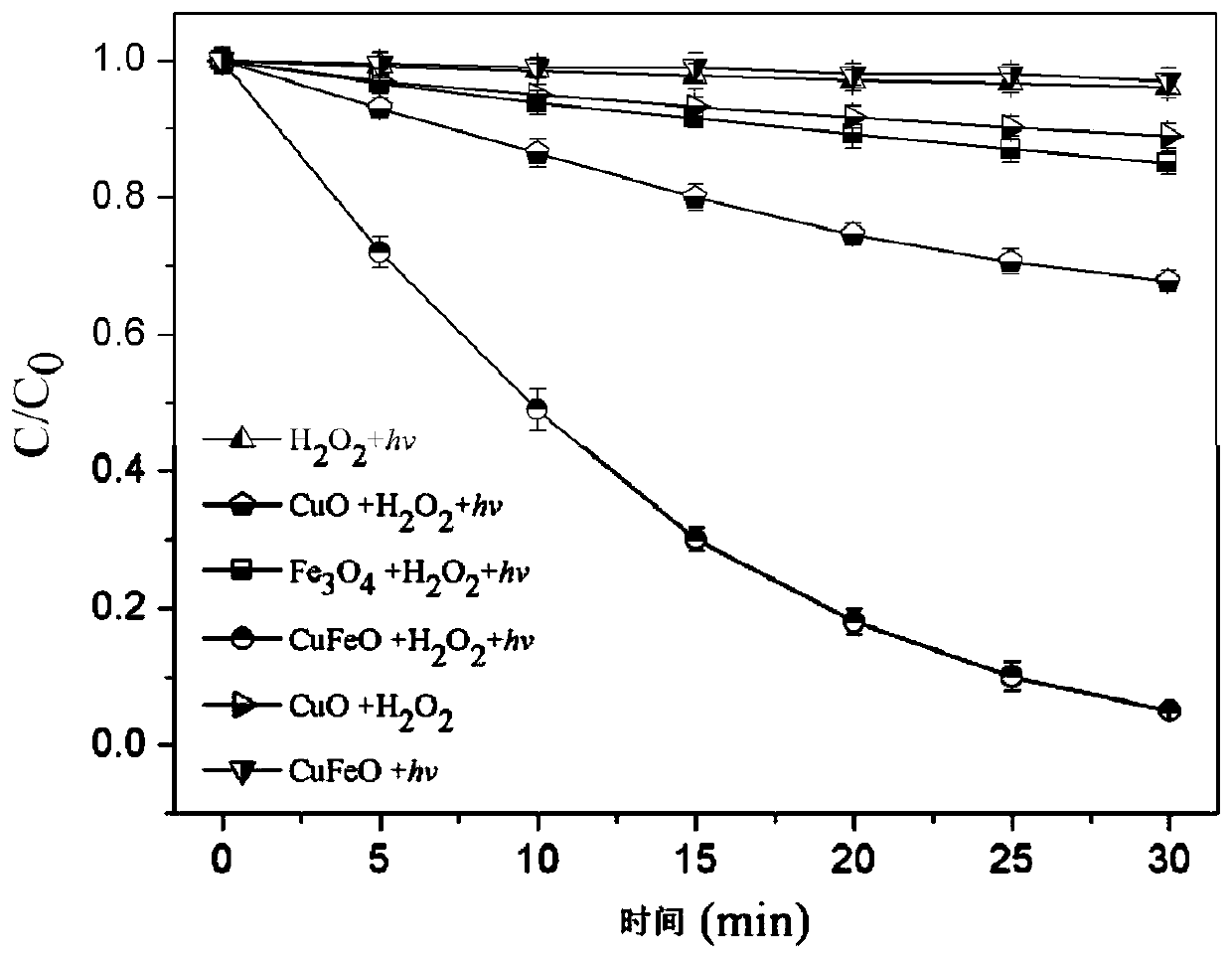

[0044] Take the sulfamethazine solution with a volume of 1L and a concentration of 50mg / L, add 0.5g of iron copper oxide and 10mL of a 30% (w / w) concentration of H 2 O 2 After the solution is uniformly m...

Embodiment 2

[0060] An application of iron-copper oxide in the treatment of antibiotic wastewater, specifically the use of iron-copper oxide to remove sulfamethazine in water, includes the following steps:

[0061] Take 4 parts of sulfamethazine solution with a volume of 1L and a concentration of 50mg / L, add 0.5g of the iron-copper oxide prepared in Example 1, and then add 10mL each with a concentration of 30% (w / w) H 2 O 2 After the solution is uniformly mixed, the initial pH of the obtained mixed solution is adjusted to 4, 6, 8, 10, and the Fenton-like reaction is performed under visible light illumination to complete the degradation of sulfamethazine.

[0062] After the Fenton-like reaction was carried out for 5min, 10min, 15min, 20min, 25min and 30min, samples were taken from the reaction system, and the content of sulfamethazine in the solution was detected by high performance liquid chromatography. The measurement results are shown in Image 6 . Image 6 It is a diagram showing the remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com