Titanium oxide material and application thereof

A technology of titanium oxide and titanium compound, applied in the direction of titanium oxide/hydroxide, electrochemical generator, electrical components, etc., can solve the problems of unsuitable electrode materials, large irreversible capacity, low Coulombic efficiency, etc., and reach a broad market Application prospect, improvement of cycle stability, and effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

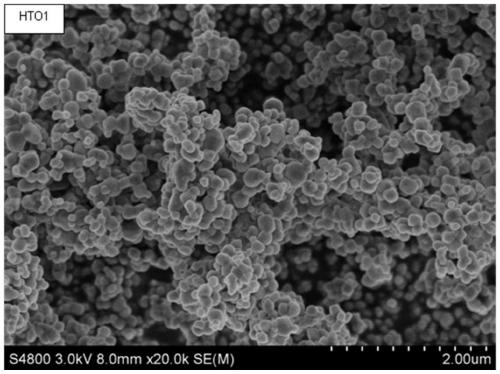

[0034] Example 1 Preparation of titanium oxide material of the present invention

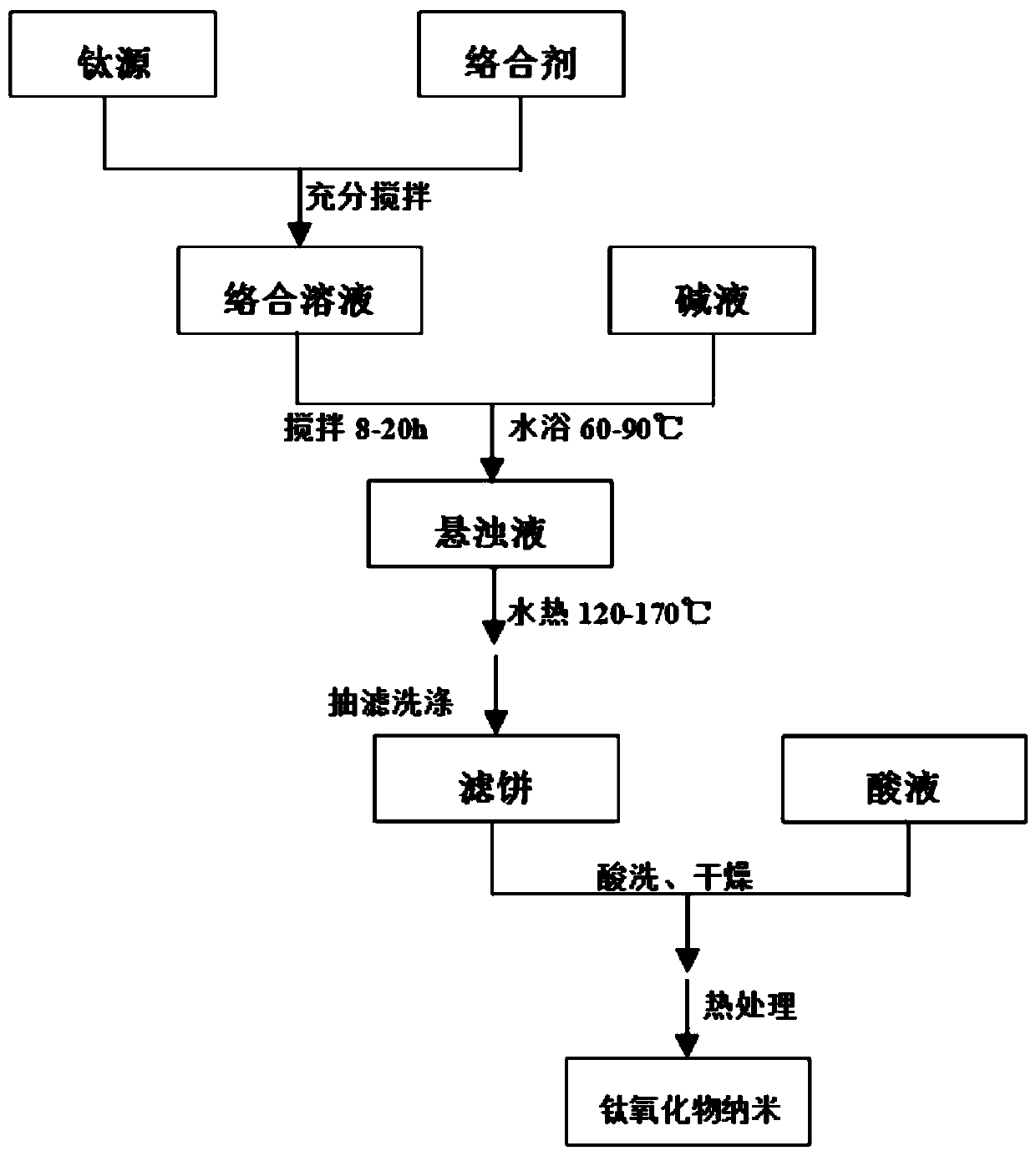

[0035] The preparation method of the titanium oxide nanomaterial of the present invention comprises the following steps:

[0036] 1) Take 4000ml of 0.5mol L-1 titanium sulfate solution, add 30% hydrogen peroxide, and stir thoroughly to obtain a complex solution, wherein the molar ratio of titanium sulfate:hydrogen peroxide is 1:1;

[0037] 2) adding concentrated ammonia water to the complex solution, controlling the pH value of the reaction solution to 10, and fully stirring for 10 h under the condition of a water bath at 60° C. to obtain a suspension;

[0038] 3) The suspension was subjected to a hydrothermal reaction at 120°C, and after 24 hours of heat preservation, solid-liquid separation was carried out, and the separated titanate precipitate was added to a 0.5mol L-1 HCl solution to control the pH of the reaction solution The value is 4.3, stirred for 5 hours, filtered, washed, and dried ...

Embodiment 2

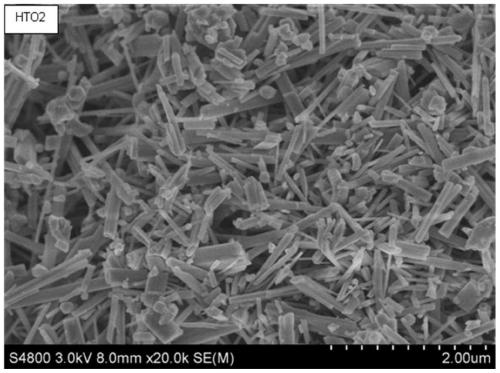

[0040] Example 2 Preparation of titanium oxide nanomaterials of the present invention

[0041] The preparation method of the titanium oxide nanomaterial of the present invention comprises the following steps:

[0042] 1) Take 4000ml of 0.5mol L-1 titanium sulfate solution, add 30% hydrogen peroxide, stir well to form a complex solution, wherein the molar ratio of titanium sulfate: hydrogen peroxide is 1:2;

[0043] 2) Add 10 mol·L-1 sodium hydroxide solution to the complex solution, control the pH of the reaction solution to 11, and fully stir for 12 hours in a water bath at 70°C to obtain a suspension;

[0044] 3) The suspension was subjected to a hydrothermal reaction at 150°C, and after 36 hours of heat preservation, solid-liquid separation was performed, and the separated titanate precipitate was added to a 1mol L-1 HCl solution to control the pH of the reaction solution was 4.3, stirred for 4 hours, filtered and washed, and dried at 90°C for 10 hours to obtain a precursor,...

Embodiment 3

[0046] Example 3 Preparation of titanium oxide nanomaterials of the present invention

[0047] The preparation method of the titanium oxide nanomaterial of the present invention comprises the following steps:

[0048] 1) Take 4000ml of 0.5mol L-1 titanium sulfate solution, add ethylenediaminetetraacetic acid, stir well to form a stable complex solution, wherein the molar ratio of titanium sulfate: ethylenediaminetetraacetic acid is 1:8;

[0049] 2) Add 8 mol·L-1 potassium hydroxide to the complex solution, control the pH of the reaction solution to 10.5, and fully stir for 12 hours in a water bath at 90°C to obtain a suspension;

[0050] 3) The suspension was subjected to a hydrothermal reaction at 170°C, and after 48 hours of heat preservation, solid-liquid separation was performed, and the separated titanate precipitate was added to a 1mol L-1 HCl solution to control the pH of the reaction solution 4.3, stirred for 5h, filtered and washed, dried at 90°C for 10h to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com