Fluorescent vegetable fiber and preparation method thereof as well as fluorescent paper and application thereof

A plant fiber and fluorescent technology, applied in the field of fluorescent paper, can solve the problems of difficult redispersion, high equipment requirements, and high price, and achieve the effects of mild reaction conditions, excellent fluorescence intensity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] According to the first aspect of the present invention, a kind of preparation method of fluorescent plant fiber is provided, comprising the following steps:

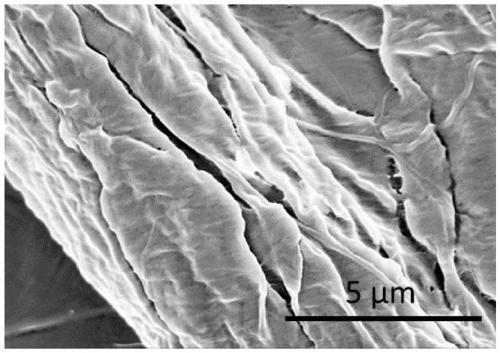

[0056] (a) plant fiber slurry is provided, and the TEMPO catalytic oxidation system is used to oxidize the plant fiber to obtain carboxyl-containing plant fiber;

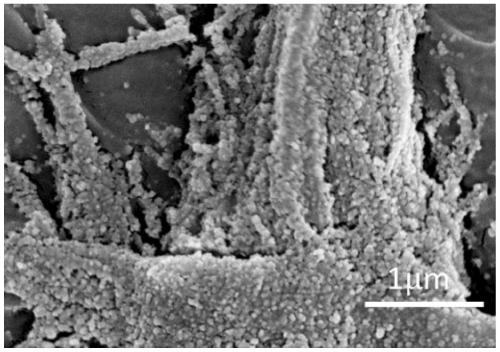

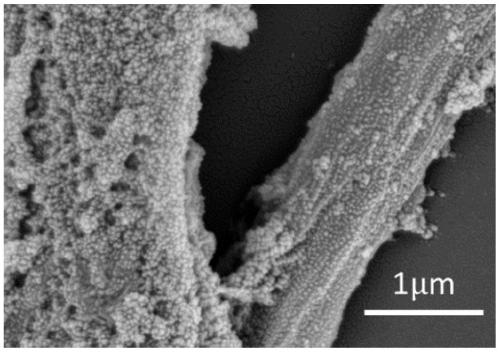

[0057] (b) Disperse the carboxyl-containing plant fibers obtained in step (a) in water, then add an aqueous solution containing rare earth ions, so that the carboxyl-containing plant fibers absorb rare earth ions, then add a precipitating agent for precipitation reaction, and obtain fluorescence after post-treatment plant fibres;

[0058] Precipitating agent is sodium fluoride or potassium fluoride.

[0059] The time for the precipitation reaction in step (b) is not limited, and it is sufficient to determine that the precipitation is complete by using methods commonly used in the art. For example, the time for the precipitation reaction can be 3-5 hour...

Embodiment 1

[0102] (1) a preparation method of fluorescent plant fiber, comprising the following steps:

[0103] (1) plant fiber containing carboxyl group

[0104] Plant fiber slurry is provided (the kind of plant fiber in the plant fiber slurry is coniferous wood fiber, and the beating degree of plant fiber slurry is 70 ° SR), takes by weighing the plant fiber slurry containing 1.0g dry fiber, and the plant fiber The slurry was added to deionized water to obtain a slurry with a dry fiber content of 1% wt.

[0105] Add TEMPO reagent (the add-on of TEMPO reagent is 0.015g) and sodium bromide (the add-on of sodium bromide is 0.1g) in the slurry of 1%wt, after mechanical stirring 25min, dropwise add NaClO aqueous solution (available chlorine The content is 6% (g / 100mL), the amount of NaClO added is 6g), the pH value is maintained at 10.5, the temperature is 25°C, and the reaction is carried out for 4h under stirring conditions. After the reaction is finished, it is purified by suction filt...

Embodiment 2

[0116] (1) a preparation method of fluorescent plant fiber, comprising the following steps:

[0117] (1) plant fiber containing carboxyl group

[0118] Plant fiber slurry is provided (the kind of plant fiber in the plant fiber slurry is hardwood fiber, and the beating degree of plant fiber slurry is 65 ° SR), takes by weighing the plant fiber slurry containing 1.0g dry fiber, and the plant fiber The slurry was added to deionized water to obtain a slurry with a dry fiber content of 1% wt.

[0119] Add TEMPO reagent (the add-on of TEMPO reagent is 0.016g) and sodium bromide (the add-on of sodium bromide is 0.1g) in the slurry of 1%wt, after mechanical stirring 25min, dropwise add NaClO aqueous solution (available chlorine The content is 6% (g / 100mL), the amount of NaClO added is 8g), the pH value is maintained at 10.5, the temperature is 25°C, and the reaction is carried out under stirring conditions for 3h. After the reaction is finished, it is purified by suction filtration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com