Environmentally-friendly bio-cellulose mask matrix and preparation method thereof

A bio-cellulose and environment-friendly technology, applied in the field of environment-friendly bio-cellulose facial mask substrate and its preparation, can solve problems such as waste of resources, and achieve the effects of less manpower consumption, lower energy consumption, and less waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

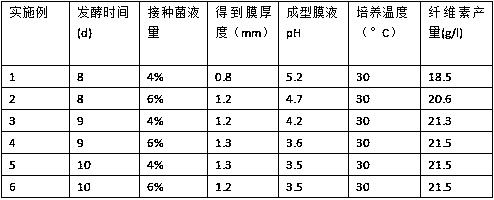

Examples

Embodiment 1

[0019] 1) Take fresh and clean banana peels, mash them in a masher for 20 minutes to form a pulp, and ferment them naturally for 24 hours, and then filter the residue in the banana peel pulp with gauze to obtain the desired banana peel extract;

[0020] 2) Transfer the banana peel extract as a culture medium into a mold, inoculate Acetobacter xyluconate, and obtain a biocellulose membrane after 8 days;

[0021] 3) Boil the biocellulose membrane obtained in step 2) in a 0.25 mol / L sodium hydroxide alkaline solution for 30 minutes to obtain a formed membrane;

[0022] 4) The formed film obtained in step 3) is repeatedly brewed with water to obtain a neutral film;

[0023] 5) Cut the neutral film obtained in step 4) to obtain an environmentally-friendly biocellulose mask substrate.

[0024] The banana peel extract and mold of the step 2) were sterilized at 120°C for 30 minutes before inoculation with Acetobacter xyluconate.

[0025] The step 2) inoculation amount is 2% of the volume of the ...

Embodiment 2

[0030] 1) Take fresh and clean banana peels, mash them in a masher for 20 minutes to form a pulp, and ferment them naturally for 24 hours, and then filter the residue in the banana peel pulp with gauze to obtain the desired banana peel extract;

[0031] 2) Transfer the banana peel extract as a culture medium into a mold, inoculate Acetobacter xyluconate, and obtain a biocellulose membrane after 8 days;

[0032] 3) Boil the biocellulose membrane obtained in step 2) in a 0.25 mol / L sodium hydroxide alkaline solution for 30 minutes to obtain a formed membrane;

[0033] 4) The formed film obtained in step 3) is repeatedly brewed with water to obtain a neutral film;

[0034] 5) Cut the neutral film obtained in step 4) to obtain an environmentally-friendly biocellulose mask substrate.

[0035] The banana peel extract and mold of the step 2) were sterilized at 120°C for 30 minutes before inoculation with Acetobacter xyluconate.

[0036] The step 2) inoculation amount is 4% of the volume of the ...

Embodiment 3

[0041] 1) Take fresh and clean banana peels, mash them in a masher for 20 minutes to form a pulp, and ferment them naturally for 24 hours, and then filter the residue in the banana peel pulp with gauze to obtain the desired banana peel extract;

[0042] 2) Transfer the banana peel extract as a culture medium into a mold, inoculate Acetobacter xyluconate, and obtain a biocellulose membrane after 9 days;

[0043] 3) Boil the bio-cellulose mask obtained in step 2) in a 0.25 mol / L sodium hydroxide alkaline solution for 30 minutes to obtain a formed film;

[0044] 4) The formed film obtained in step 3) is repeatedly brewed with water to obtain a neutral film;

[0045] 5) Cut the neutral film obtained in step 4) to obtain an environmentally-friendly biocellulose mask substrate.

[0046] The banana peel extract and mold of the step 2) were sterilized at 120°C for 30 minutes before inoculation with Acetobacter xyluconate.

[0047] The step 2) inoculation amount is 4% of the volume of the medium....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com