Preparation and application of cubic spinel type Mn/Al oxide-sludge biochar material

A spinel-type, biochar technology, applied in water/sludge/sewage treatment, water pollutants, water/sewage treatment, etc., to achieve the effect of stable source, large specific surface area and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

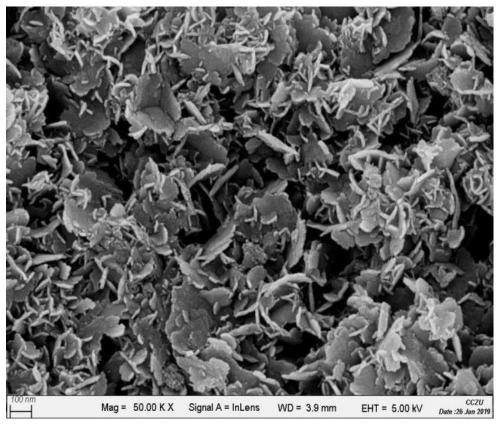

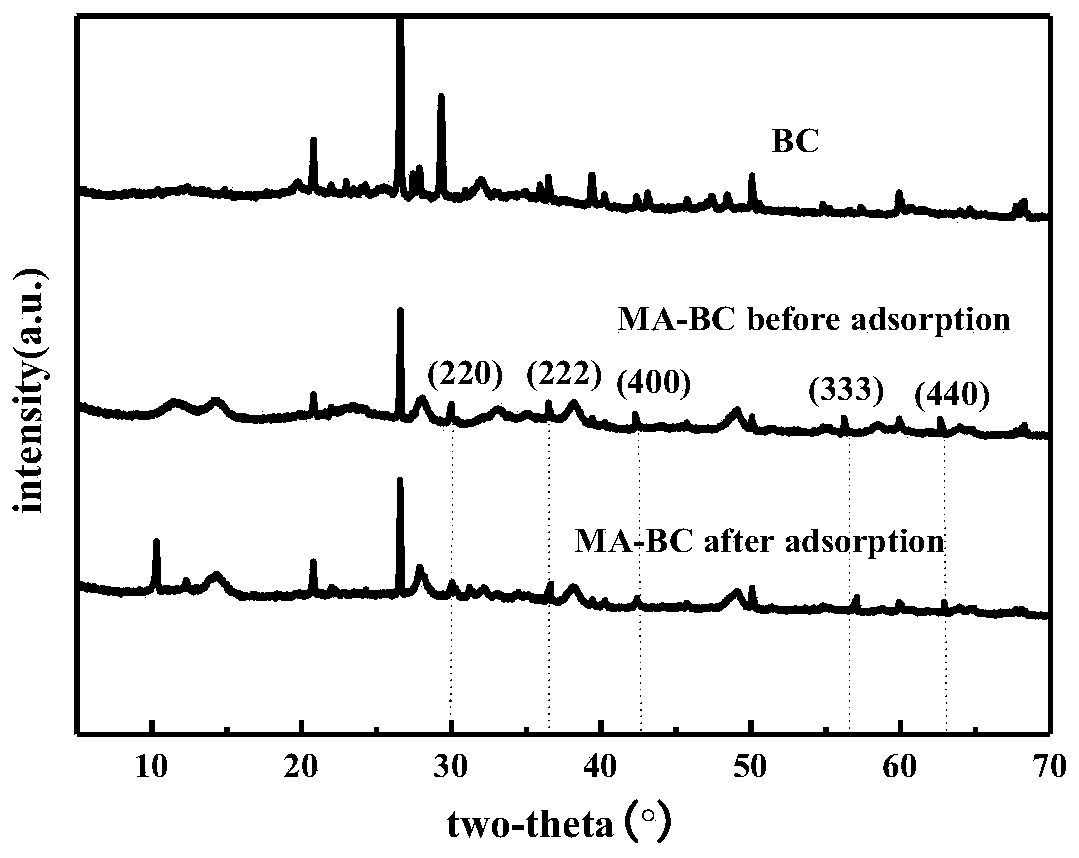

[0024] Preparation of cubic spinel Mn / Al oxygen body-sludge biochar: first, dehydrated sludge was dried to constant weight at 105 °C, and ground through a 200-mesh sieve. Then 2.5 g of powdered sludge was added to 50 mL of deionized water and stirred for 1 h to disperse evenly in the solution, and then 0.01 mol of manganese chloride tetrahydrate (MnCl 2 4H 2 O) and 0.02 mol aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) Dissolve into the solution containing the sludge powder and keep stirring with a magnetic stirrer for 30 min. During stirring, 5 M NaOH was added dropwise to the mixed solution until the pH was greater than or equal to 10. Subsequently, the mixed solution was transferred to a 100 ml polytetrafluoroethylene-lined stainless steel hydrothermal reactor and reacted at 453 K for 12 h. After the reaction was finished and cooled naturally, the filtered precipitate was washed with deionized water until neutral, and finally dried at 333 K for 24 h. The obtained sampl...

Embodiment 2

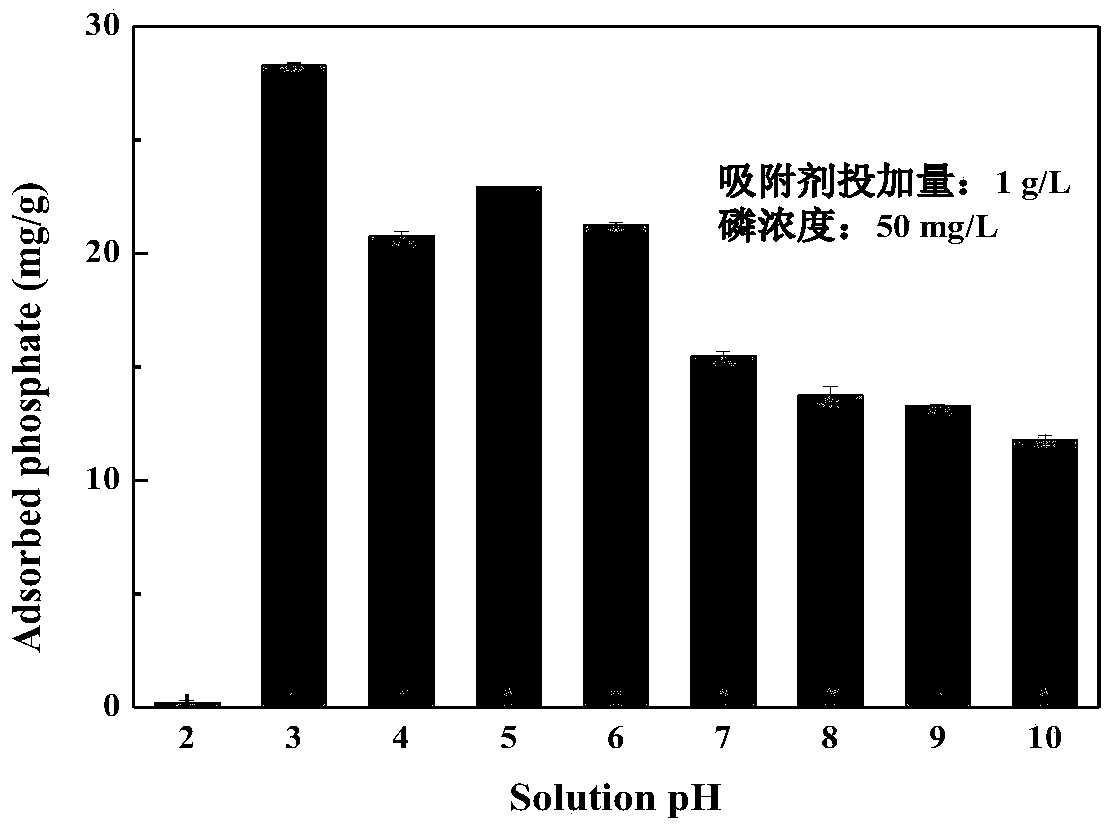

[0027] The effect of different pH values on MA-BC adsorption and removal of phosphorus in Example 1: Weigh 0.1 g MA-BC and add it to a conical flask containing 100 mL of phosphate solution with a concentration of 50 mg / L, and use 0.1M HCl and NaOH adjusted the pH of the solution to 2-10 with an interval of 1, and then placed the Erlenmeyer flask in a constant temperature shaker at 298 K for 24 h. After the adsorption was completed, the supernatant was taken, filtered through a 0.45 μm membrane, and the phosphate concentration was detected with a UV-vis spectrophotometer. The result is as image 3 As shown, when the pH is equal to 3, the maximum adsorption capacity is 28.2 mg / g. When the pH is equal to 2, the adsorption amount is the smallest, about 0.2 mg / g. When the pH is greater than 3, the adsorption amount shows a decreasing trend as the pH increases.

Embodiment 3

[0029] The MA-BC prepared in Example 1 was used for the kinetics study of adsorption and removal of phosphorus: Weighed 0.1 g of MA-BC and added it to a conical flask containing 100 mL of phosphate solution with a concentration of 50 mg / L, and adjusted The pH of the solution was 3, and then the Erlenmeyer flask was placed in a constant temperature shaker at 298 K for 48 h, and the solution was shaken at different time periods (1 min, 5 min, 10 min, 30 min, 1 h, 2 h, 5 min, h, 12 h, 24 h, 36 h, 48 h) Take the supernatant, filter it with a 0.45 μm membrane, and detect the phosphate concentration with a UV-vis spectrophotometer. The result is as Figure 4 As shown, the adsorption rate was faster before 10 min, then the adsorption rate began to decrease, and finally reached equilibrium at about 36 h, and the adsorption amount at equilibrium was 31.2 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com