Fermenting-modified composite biochar for treatment of urban wastewater and preparation method thereof

A technology for urban sewage and biochar, which is applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Uniformity and other problems, to achieve the effect of many adsorption active sites, cheap raw materials, and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

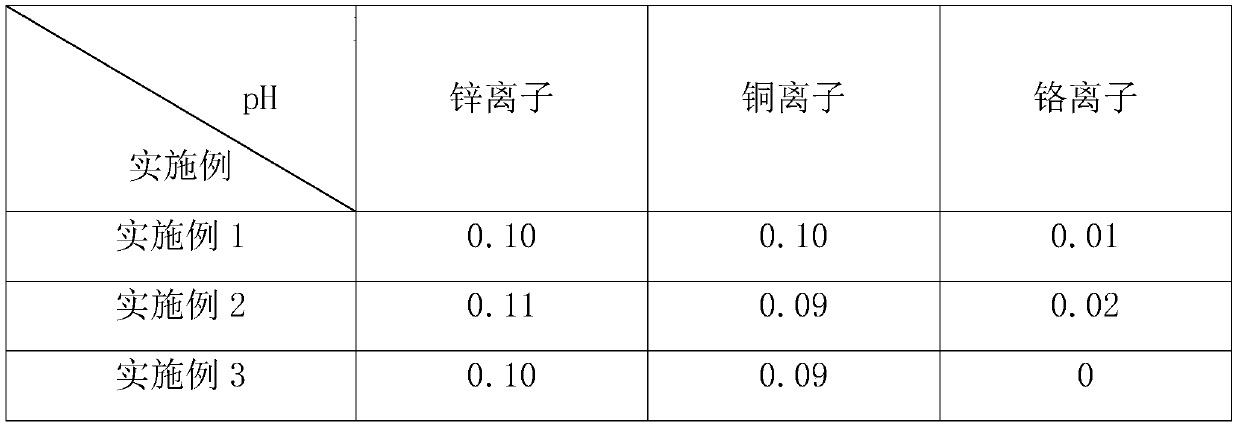

Examples

Embodiment 1

[0027] Embodiment 1: the preparation one of biochar:

[0028] Raw material pretreatment: cut 150g of fresh lotus leaves into small pieces of about 3cm, cut 80g of fresh knotweed into small pieces of about 7cm, then dry the petiole of lotus leaf at 70°C for 2h, and then add knotweed , after the two are blended, dry at a temperature of 70°C until the water content of the petiole of the lotus leaf and the knotweed is lower than 25%;

[0029] The fresh lotus leaf petiole has more water content, so the drying time is longer than that of knotgrass. After mixing the two, dry it until the water content is lower than 25%. Next step.

[0030] Fermentation: Mix the pretreated lotus leaf petiole and knotweed with 40g of 2cm corn stalks and 30g of peanut shells to obtain a mixture, and spray the polyphenol oxidase solution with a concentration of 0.8U / g on the mixture. Stir evenly until the water content is 45%, then ferment for 18 days in an environment with a temperature of 18-20°C and...

Embodiment 2

[0036] Embodiment 2: the preparation two of biochar:

[0037] Raw material pretreatment: cut 200g of fresh lotus leaves into small pieces of about 3cm, cut 100g of fresh knotweed into small pieces of about 7cm, then dry the petiole of the lotus leaf at 70°C for 2 hours, and then add knotweed , after the two are blended, dry at a temperature of 70°C until the water content of the petiole of the lotus leaf and the knotweed is lower than 25%;

[0038] Fermentation: Mix the pretreated lotus leaf petiole and knotweed with 40g of 3cm corn stalks and 30g of peanut shells to obtain a mixture, and spray the polyphenol oxidase solution with a concentration of 0.9U / g on the mixture. Stir evenly until the water content is 45%, then ferment for 18 days in an environment with a temperature of 20-22°C and a humidity of 72-74%, turn over every 6 days, and oxidize the fermented mixture with 1wt% hydrogen After soaking in sodium solution for 35min, wash twice with 3wt% hydrogen peroxide, filte...

Embodiment 3

[0042] Embodiment 3: the preparation three of biochar:

[0043] Raw material pretreatment: cut 250g of fresh lotus leaves into small pieces of about 4cm, cut 50g of fresh knotweed into small pieces of about 10cm, then dry the petiole of the lotus leaf at 75°C for 2 hours, and then add knotweed , after the two are blended, dry at a temperature of 70°C until the water content of the petiole of the lotus leaf and the knotweed is lower than 25%;

[0044] Fermentation: Mix the pretreated lotus leaf petiole and knotweed with 50g of 3cm corn stalks and 20g of peanut shells to obtain a mixture, and spray the polyphenol oxidase solution with a concentration of 1U / g on the mixture until The water content is 48%, stirred evenly, then fermented in an environment with a temperature of 21-23°C and a humidity of 73-75% for 18 days, turning over every 6 days, and using 1wt% sodium hydroxide to ferment the mixture After the solution was soaked for 40 minutes, it was washed twice with 3wt% hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com